©I.CH Motion® 2020

ichmo

.com

Specifications subject to change without notice.

Owner's Guide: 3P20M Hybrid Stepper Motor Driver

Page 9

TECHNICAL DOCUMENT

Selecting Supply Voltage:

The power MOSFETS inside the 3L583M can actually operate within +18

~

50VDC, including power input fluctuation and back EMF voltage

generated by motor coils during motor shaft deceleration. Higher supply voltage can increase motor torque at higher speeds, thus helpful for

avoiding losing steps. However, higher voltage may cause bigger motor vibration at lower speed, and it may also cause over-voltage protection or

even driver damage. Therefore, it is suggested to choose only sufficiently high supply voltage for intended applications, and it is suggested to use

power supplies with theoretical output voltage of +24

~

+ 45V, leaving room for power fluctuation and back-EMF.

9. Output Current and Microstep Resolution Settings

Current Setting

For a given motor, higher driver current will make the motor output more torque, but at the same time causes more heating in the motor and

driver. Therefore, output current is generally set to be such that the motor will not overheat for long time operation. Phase current rating supplied

by motor manufacturer is important in selecting driver current, however the selection also depends on leads and connections.

DIP Setting for Dynamic Current

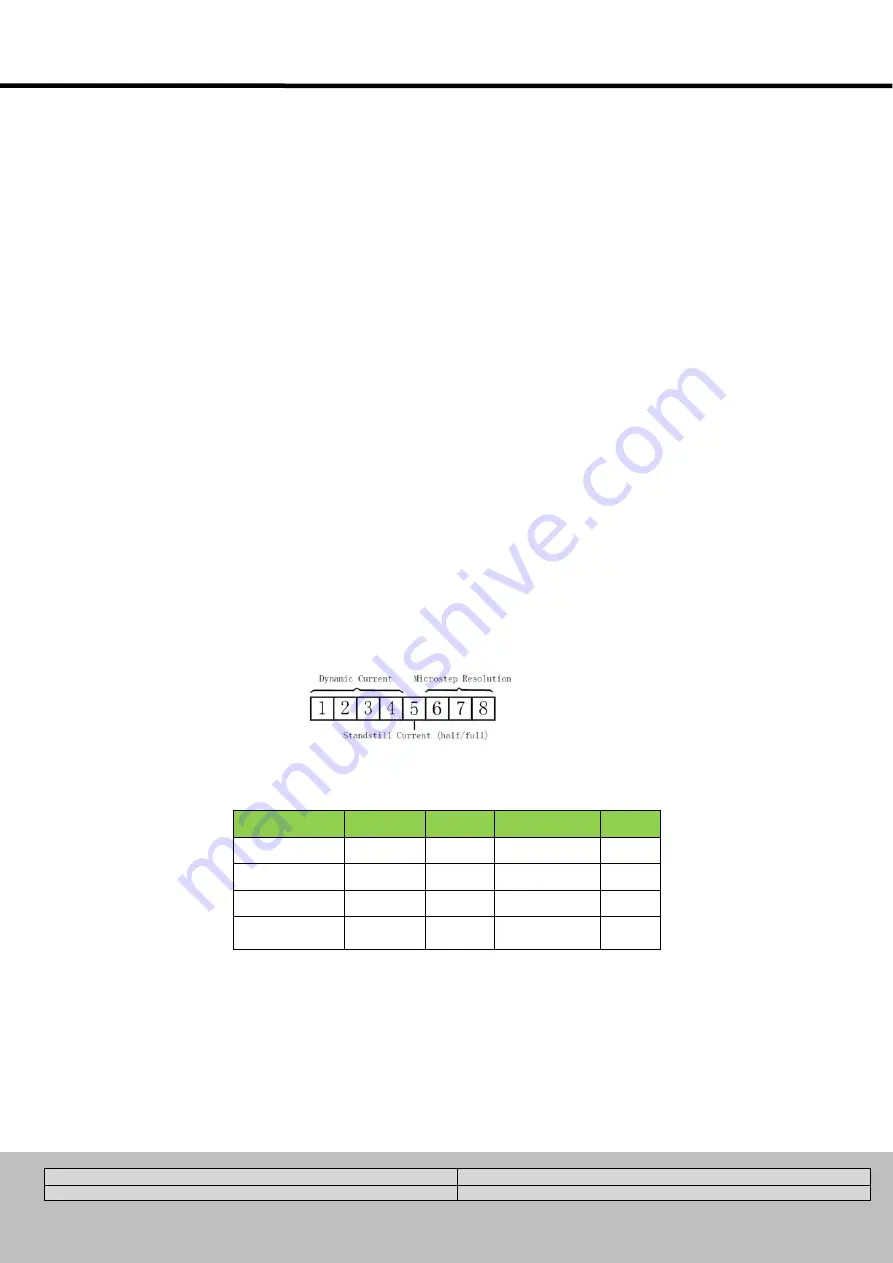

The 3P20M uses an 8-bit DIP switch to set motor dynamic current, standstill current and microstep resolution, as shown below:

The first four bits (SW1, 2, 3, 4) of the DIP switch are used to set the dynamic current. Select a setting closest to your motor’s required current.

Peak current (A)

RMS (A)

SW1

SW2

SW3

2.1

1.5

OFF

OFF

OFF

2.5

1.8

ON

OFF

OFF

2.9

2.1

OFF

ON

OFF

3.2

2.3

ON

ON

OFF