36

Caution:

care must be taken to avoid the metal scrap from flying out, leading to personal injury. Wear the goggles

or the safe glasses or safe devices suitable for operations!

Change the bucket

Caution:

while hitting out or into the connecting pin, care must be taken to prevent against any personal injury

due to out-flied metal scrap. Wear the goggles or the safe glasses or safe devices suitable for operations!

1.

Park the machine on flat ground and lower the flat surface of bucket onto ground to make sure the bucket

does not move after the removal of pin.

2.

Slide the O-ring out, as shown in the figure.

3.

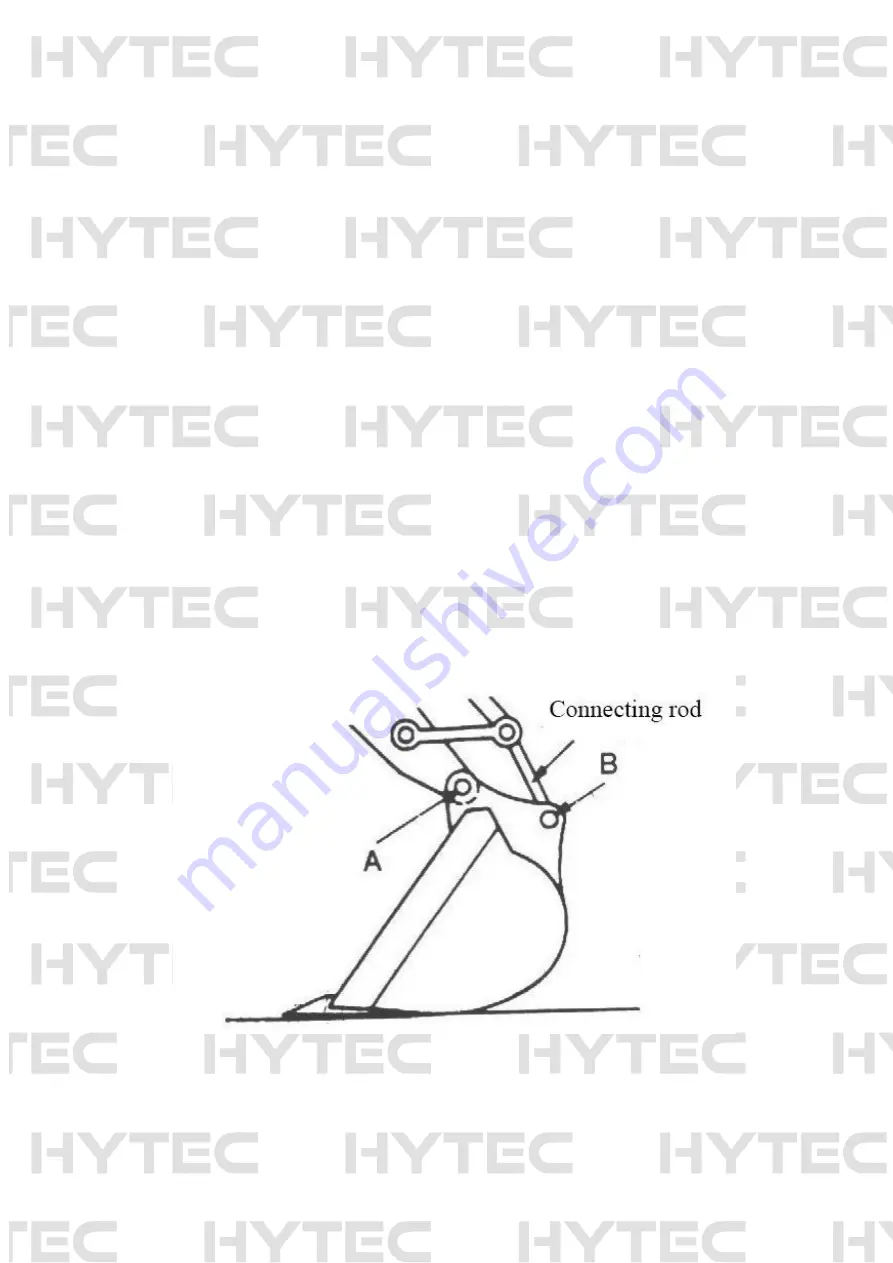

Remove the bucket pins A and B to separate the bucket and the arm. Clean the pin and its pin hole and then

properly grease them.

4.

Adjust the arm and the new bucket correctly, and make sure the bucket does not roll away. .

5.

Install the bucket pins A and B.

6.

Put the locker and ring onto pins A and B.

7.

Adjust the connection clearance of bucket at pin A. Refer to the way to adjust the bucket connection

clearance.

8.

Grease the pins A and B.

9.

Start up engine and run it at low speed. Slowly rotate the bucket to two directions to check if there is any

interference to movement of bucket. Do not use any machine with interference, which should be solved

immediately. .

Summary of Contents for F1000

Page 1: ...1 HYTEC F1000 EXCAVATOR OPERATION PARTS MANUAL ...

Page 4: ...4 Quick hitch Narrow bucket Log grab Mechanical thumb Auger Ripper Rake ...

Page 5: ...5 Section II Main performance parameters ...

Page 11: ...11 Hydraulic system structure of HYTEC F1000 Excavator I Rotary motor ...

Page 12: ...12 ...

Page 15: ...15 ...

Page 16: ...16 Section IV Schematics of main valve ...