12

CAUTION

Use only Hyster approved brushes to protect

commutator and to obtain maximum brush life.

1

2

3

4

SHUNT

LENGTH

SHUNT

LENGTH

5

6

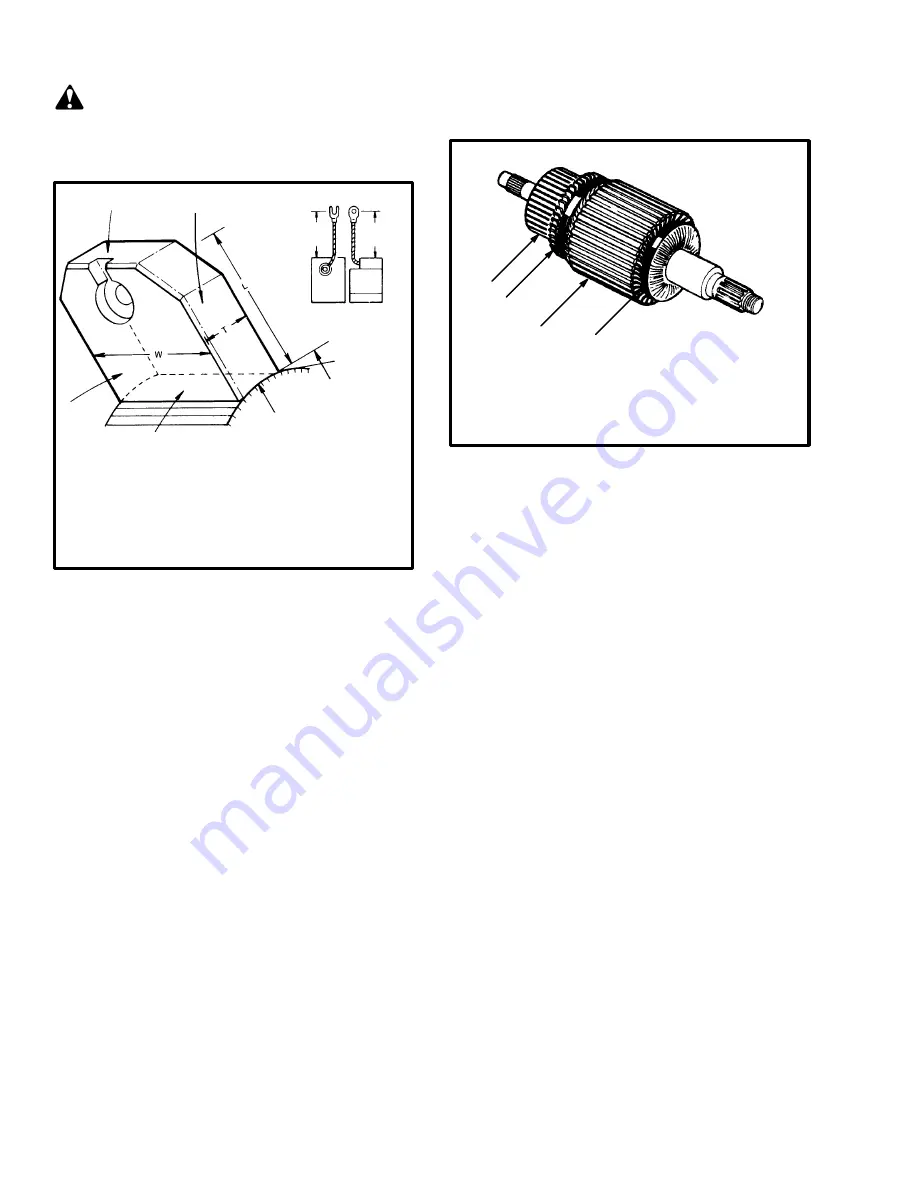

FIGURE 15. BRUSH DESIGN DETAIL

1. COMMUTATOR END

2. FRONT SIDE

3. TOP

4. RIGHT SIDE

5. BEVEL

6. CONCAVE FACE

6936

ARMATURE

The armature assembly consists of several laminations

of iron located around a steel shaft, the copper armature

windings and a commutator. Each commutator segment

is separated by heat resistant, nonconducting material,

and is attached to an armature coil. Circular bands hold

the armature coils in place. Between each copper

armature band is a laminated iron core. These reinforce

the magnetic field for each coil field. The armature is

wired so current from one brush makes contact with a

commutator bar, energizes an armature coil and returns

through another commutator bar and brush. As the

armature assembly turns, alternate commutator

segments are energized changing the polarity of the

armature coils in rotating sequence (May vary among

motor manufacturers.)

1

2

3

4

FIGURE 16. ARMATURE ASSEMBLY

1. LAMINATED IRON CORES

2. COMMUTATOR

3. ARMATURE COILS

4. BAND

6937

COMMUTATOR

Description

The commutator is formed of alternate copper segments

(bars) and mica plates. The mica plates physically

separate and electrically insulate the bars. The mica

plates are undercut below the commutator surface to

prevent interference with the sliding action of the

brushes on the surface of the commutator. The bars are

wedge shaped and form a cylinder when assembled.

Each bar has a riser at one end to make armature coil

connections. The bars are held in position by the

clamping action of a wedge ring with lock nut (or

manufactured integral). Mica cones, contoured to fit

between the shell and wedge ring insulate the bars from

ground (armature). The commutator provides sliding

electrical contact between the brushes and the moving

armature coils. It acts as a reversing switch to allow the

current to flow through the coils in the proper direction

at all times.