15

P/N 42-9452 8/08 Copyright Hydrotherm

KN USER’S CONTROL MANUAL

Method 2: HeatNet modulation – BMS control

(cont.)

2

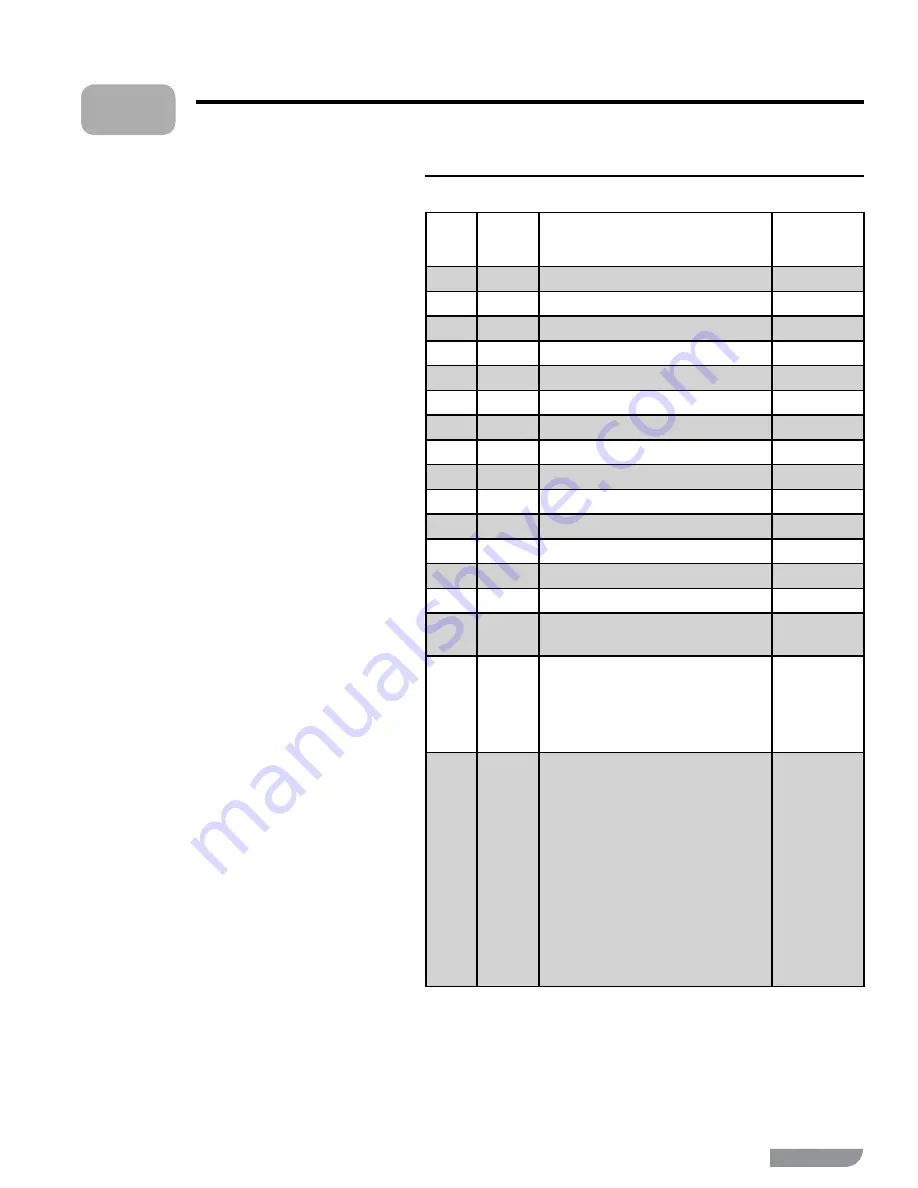

Table 5

Modbus input (read-only) registers

Address

Data

Type

Description Valid

Values/

Range

30001

Unsigned Boilers Running

0 – 16

30002

Unsigned Modulation (% BTU Load)

0 – 100

30003

Signed

Header / System Temperature

32 – 250 °F

30004

Signed

Supply Temperature

32 – 250 °F

30005

Signed

Return Temperature

32 – 250 °F

30006

Signed

Outside Air Temperature

-40 – 250 °F

30007

Signed

Spare Input 1

-32768 to 32767

30008

Signed

Spare Input 2

-32768 to 32767

30009

Unsigned Clock – Month

0 – 11

30010

Unsigned Clock – Day

1 – 31

30011

Unsigned Clock – Year

0 – 99

30012

Unsigned Clock – Hours

0 – 23

30013

Unsigned Clock – Minutes

0 – 59

30014

Unsigned Clock – Seconds

0 – 59

30015

Unsigned Clock – Day of Week

1 – Monday 7 –

Sunday

30016 –

30047

Unsigned Boilers 1 – 16 status fl ag (32-bit) registers. The

upper 16-bits of each 32-bit register is stored at

odd numbered addresses 30016 –30046. The

lower 16-bits of each 32-bit register is stored at

even numbered addresses 30017 – 30047.

See the Boiler

Status Flags

Table Below

30048 –

30079

Unsigned Boilers 1 – 16 runtime (32-bit) registers. The

upper 16-bits of each 32-bit register is stored at

odd numbered addresses 30048 – 30078. The

lower 16-bits of each 32-bit register is stored at

even numbered addresses 30049 – 30079.

When the upper and lower registers are combined

they form a 32-bit unsigned integer that is the

number of seconds that the boiler has been

running. For instance: (((Register 29) * 65536)

+ Register 30) = Boiler 1 runtime in seconds.

Boiler 1 is the master boiler. Boilers 2 – 16 are

member boilers.

0 – 4294967295

seconds

BACnet or LonWorks protocols

Install the correct bridge to adapt to building management

systems using BACnet or LonWorks protocols.

Th e bridge translates the BACnet or LonWorks input to

the Modbus protocol for compatibility with the HeatNet

controls.

Wiring and set-up

Wire and set up the master boiler and member boilers exactly

as for HeatNet modulation — local control applications.

See page 6 through page 13.

ALL control parameters must be set up just as for the local

control method.

Th

e ONLY diff erence in setup is the termination DIP switch

sett ings. Use the sett ings for Modbus communications given

in Table 1, page 11.

Connect communications cables (RJ45 or shield-wire

cables) between the control communications boards as for

the local control method.

Verify network operation BEFORE connecting the building

management system.

Connect the BMS cable

DO NOT connect the building management system cable

until the boiler network has been proven to operate inde-

pendently. Th

e system is designed to revert to local control

by the master boiler should communications with the

building management system be lost.

Turn off power to the master boiler.

See Figure 10, page 13. Connect an RJ45 cable to the BMS

input port, item 6. Or use shielded wire cable, connected to

terminal block, item 3.

Verify BMS/HeatNet operation

Turn on power to the master boiler.

Allow the master boiler to initialize.

Verify operation with the building management system.

1.

2.

1.

2.

3.

4.

5.

1.

2.

3.

1.

2.

3.