2.18

If the saw is fitted with a blade coarser than optimum (e.g.: 1.4/2.5 TPI) we can still use the graph, but we go to the 1.4/2.5

curve. As a result we find that the FEED RATE is decreased to 1.3 in/min (133mm/min) for this blade. If however, the

machine is fitted with a finer than optimum blade (e.g. 3/4 TPI) we use the graph for the optimum blade as before, and

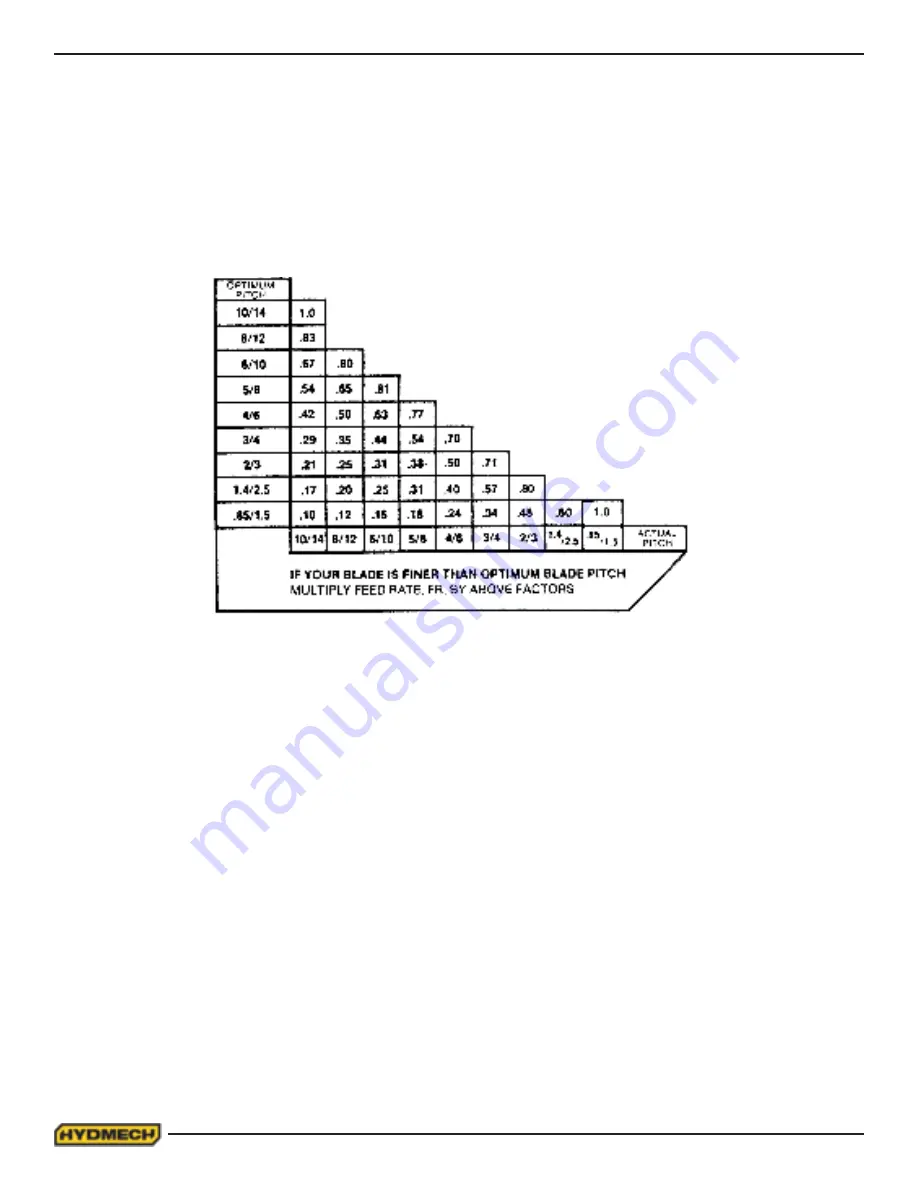

then use a multiplier given by the table below.

Optimum Vs Actual Blade Pitch

ADDITIONAL CUTTING SETUP EXAMPLES

EXAMPLE # 2

Material:

Round Steel Tube SAE 4320 - Hardened to 35 RC (325 Bhn )

Dimensions - 6” O.D. x 4” I.D. (150mm O.D. x 100mm I.D.)

Step 1

Effective Material Width: 4 1/2” (.75 X 6) 114mm (19 x 6)

Step 2

Feed Force limit setting for 6” Diameter material (Refer to Feed Force Limit, Setting in Step 2)

Step 3

Optimum blade pitch (TPI): 3/4 T. P. I.

Actual blade pitch on the saw: 4/6 T. P. I.

Step 4

Optimum blade speed for 4 1/2” effective 225 ft/min (70m/min) material width

Blade speed reduced by hardness factor: 225 ft/min X .60 = 135ft/min (70m/min x .60 = 42m/min)

Step 5

Feed Rate for 3/4 TPI blade: 1.8 in/min (45mm/min)

Feed Rate for 4/6 TPI blade: 1.8 in/min X .70 = 1.3in/min

(reduced by finer than optimum blade pitch factor) (45mm/min x .70= 31.5mm/min)

FEED RATE, continued

Summary of Contents for M16A

Page 2: ...2 ...

Page 3: ...2 ...

Page 38: ...2 20 ...

Page 55: ...4 1 ELECTRICAL SCHEMATICS SEE PDF ON ATTACHED CD SECTION 4 ELECTRICAL ...

Page 56: ...4 2 ...

Page 61: ...6 2 ...

Page 68: ...7 7 AUTOMATIC MODE SCREEN Fig 8 ...

Page 72: ...8 2 M16A LAYOUT ...

Page 74: ...8 4 M20A LAYOUT ...

Page 76: ...9 2 ...