11

A discharge check valve must be placed between

the aftercooler and the discharge receiver. This is

especially important on booster compressors, as

high pressure gas (or air) may leak back through the

compresor to the suction side of the system, causing

dangerously high pressures in the suction side

receivers, piping, etc.

On initial start-up of the compressor, bubble test all

piping connections for leaks with a soap-water solution.

All piping must be leak free.

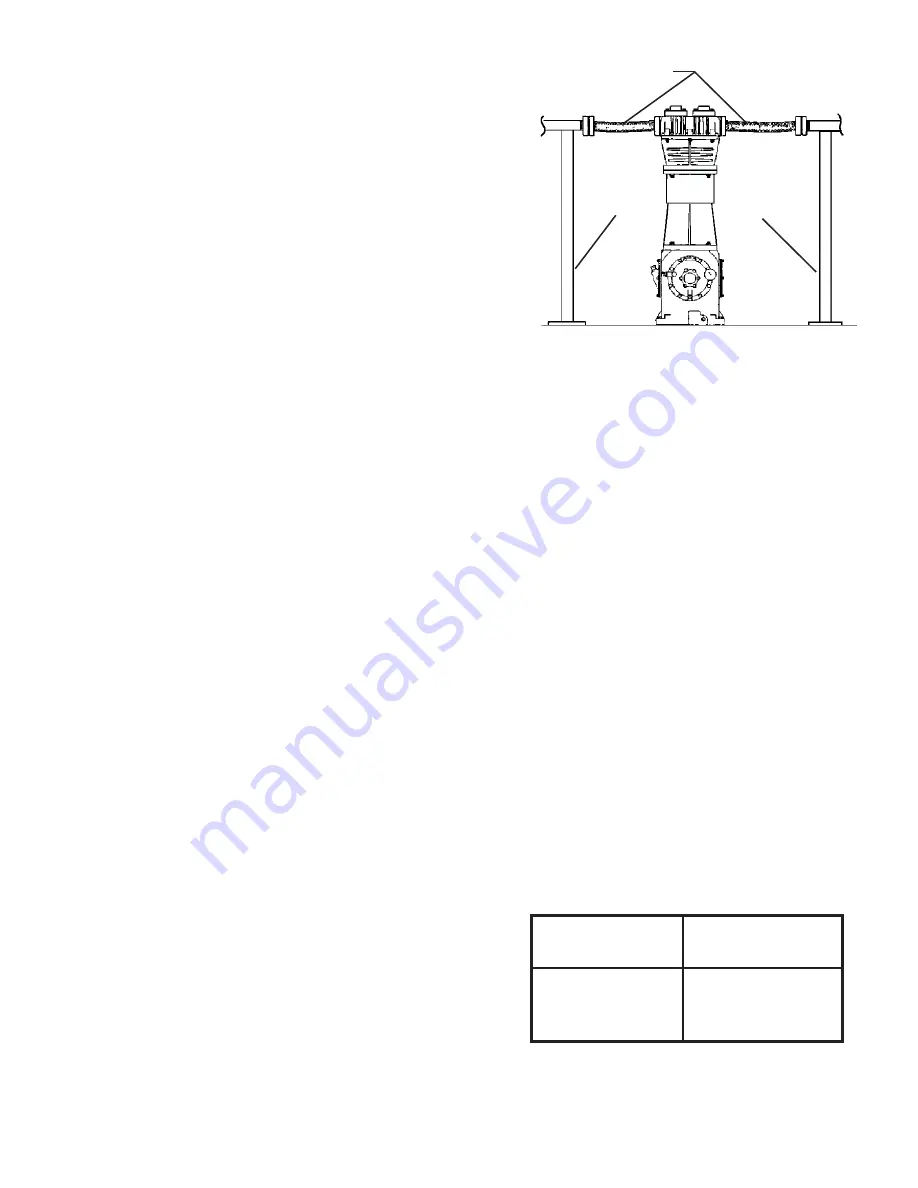

Flexible expansion joints must be placed within 36

inches of the compressor to help compensate for

expansion/contraction of the pipes, as well as isolate

the vibration of the compressor from the rigid piping.

All piping must be adequately supported to ensure no

piping loads are placed upon the compressor (see

Figure 5). Failure to do so may cause a dangerous

break in the rigid pipe caused by vibration in the

piping.

All piping must be compatible with the gas being

compresssed, and must be rated above the working

pressure of the system.

Compressor

Horsepower

1-3

5-15

20-50

Receiver size

Gallons / HP

20-40

15-20

8-12

be rated for the working pressure of the inlet gas, and

protected with a properly sized safety valve set at 20

to 30 PSI above the maximum operating pressure but

below the maximum allowable working pressure of

the pipe.

An inlet

fi

lter must be placed in-line with the inlet, to

ensure clean gas (or air) to the booster. The

fi

lter

should be a 1.0 micron or better, coalescing type,

suf

fi

ciently sized for twice the full

fl

ow of the booster

with minimal pressure drop. Inlet

fi

lters should be

installed on the upstream side of an inlet receiver to

prevent pulsation damage. The inlet receiver and

piping must be cleaned of any foreign residue before

compressor startup. Unless otherwise indicated, air

boosters and gas compressors do NOT come with an

inlet gas

fi

lter. Damage to the machine will occur if

contamination is drawn into the booster compressor

and will void the warranty!

Hycomp air boosters and gas compressors require

an inlet receiver to be installed just upstream of the

booster compressor. See RECEIVERS (Air Boosters

& Gas Compressors) for additional sizing details. See

Figure 4 for additional details.

Compressors are not designed to pump any liquids.

Liquids are non-compressible and even the slightest

amount of liquid can cause high-impact stresses

resulting in serious damage to the compressor. The

use of a liquid trap in the suction line is required where

the presence of entrained liquids in the suction gas is

a possibility.

DISCHARGE PIPING

Recommended practice is to have a compressor

aftercooler, discharge safety valve, discharge check

valve, and an air receiver. To prevent undesirable

pressure drops in piping, pipe size should be

increased one size for each 100 feet of run. Sweat

type copper

fi

ttings, when compatible with the gas

being compressed, will give much less pressure loss

than the equivalent size steel pipe. All horizontal pipe

runs should be sloped away from the compressor at

about one quarter inch per foot. All low points in the

piping system should have a drain leg to catch any

accumulation of condensation in the piping.

It is extremely important that a properly sized safety

valve, set at 10% or 20 to 30 PSI above the maximum

operating pressure but below the maximum allowable

working pressure of the system components, be

placed at the discharge receiver and upstream of the

aftercooler. Never place a line valve in the discharge

piping between the compressor discharge and the

safety valve.

Flex Connectors

Rigid Pipe

Support

Rigid Pipe

Support

Table 1: Receiver Sizing for Ambient Air

Compressors

Figure 5: Piping Connections