START-UP & ADJUSTMENTS

MI35.2505

02JAN96

Do NOT operate system without having the ground

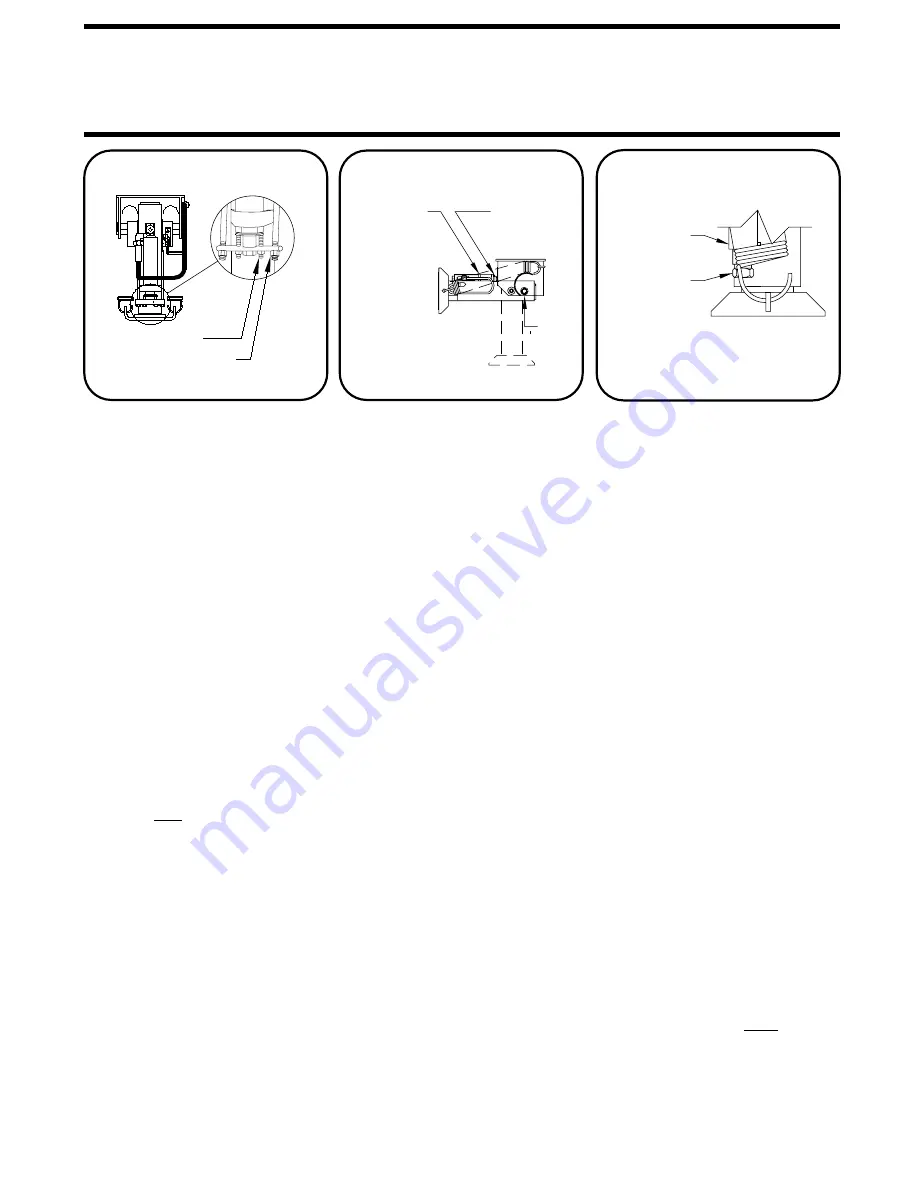

FIGURE 10

16000# JACK

FIGURE 11

SET SCREW

ADJUSTING

HEAVY DUTY

LEVELING

CAP

UNITS

ADJUSTING NUTS

SET SCREWS

FIGURE 9

9000# JACK

LOWER

ADJUSTING

LOW PROFILE

STANDARD &

UNITS

NUT

UPPER

ADJUSTING

NUT

STOP

A. HYDRAULIC START-UP

1. PRIMING PUMP

4-LEVER:

turn the master switch on. Move any lever on the manual

system to the EXTEND postion. The lever must be moved

to the fullest extent of its travel. This should be done in 3-

second intervals until the pump is primed. This can be de-

termined by a lower pitch sound from the pump. Extend the

two front jacks until they bump the ground, then RETRACT and

Check the system for hydraulic leaks.

Check that the correct jacks are operating as each lever is

operated.

Refill hydraulic tank to within 1" of the top after all jacks have

have been operated.

B. JACK ADJUSTMENTS

Horizontal stop is adjusted by turning the set screws located

just inside the cable locknuts. The jack can be adjusted down

to provide clearance for objects which may interfere with the

operation of the jacks. The horizontal stop must be adjusted to

provide clearance in case the jack extends in the horizontal posi-

tion. The jack must be able to fully extend in the horizontal posi-

tion without interfering with suspension components, tanks,

etc.

Each jack should be checked to be sure that it is vertical when

it swings down. To do this retract all jacks, then extend each

jack until it is close to but not touching the ground. Each jack

it can be adjusted by loosening the lower actuator nut and

tightening the upper actuator nut. (FIGURE 10) If the jack

provide clearance for objects which may interfere with the

operation of the jack (FIGURE 10). The stop must be adjusted

so that the jack can be fully extended in the horizontal pos-

ition without interfering with suspension components or tanks,

etc.

If the jack stopped short of being vertical,

the jack went beyond vertical, loosen the set screw and turn

the adjusting cap counterclockwise. After each counterclock-

wise adjustment, the weight of the coach must be applied to

the jack to make the adjustment effective. Do NOT adjust cap

more than one turn without cycling the jack (FIGURE 11). The

horizontal stop on the heavy-duty jack is adjusted by adding

washers under the urethane stop.

The horizontal stop can be adjusted up or down in the slot to

loosen the set screw and turn the adjusting cap clockwise. If

wire grounded properly to the chassis.

Consult the respective operator’s manuals for specific operat-

ing instruction for the system being installed.

6000# JACK

PART IV

To prime the pump turn the ignition key on, then

NOTE:

1. 6000# JACKS:

2. 9000# JACKS:

3. 16000# JACKS:

- KICK DOWN JACKS ONLY

If the jack stopped short of being vertical

must be adjusted so it can extend in the horizontal position

without interfering with any suspension components, tanks,

etc.

goes past vertical reverse the process.

refill the tank. Care should be taken not to run the pump

out of fluid as it may damage the pump.

Always make the vertical adjustment first.

If the vertical adjustment is changed at any time, be sure

to check the horizontal adjustment. Vertical adjustment is

changed by adjusting the locknuts on the actuator cable.

(FIGURE 9) If the jack stopped short of vertical, tighten the

locknuts off. If the jack goes past vertical, back the lock-

nuts off. Be sure to adjust each nut the same number of

turns.