PART III

MI35.2015

25AUG95

5. WIRING: Refer to the appropriate electrical diagram for

wiring. Any wire or cable in the interior of the coach is to be

protected by fusing. All wire insulation should be rated 125

deg. Celsius (257 deg. F). Check applicable RVIA or other

code for detailed fusing and wiring information. Protecting

all wires and cables by fusing is desirable.

A #2 battery cable is supplied with most systems to connect

the pump to the battery or a battery junction post. If a different

cable is used it must be able to carry 200 amperes. If fusing

is required, use a 200 ampere fuse. The fuse should be placed

near the power source. Never connect a fuse directly to the

battery or place it in the battery box where an electrical spark

can cause the battery to explode. If power is taken directly

from the battery, the fuse should be at least 18" from the bat-

tery. A fuse kit is available from HWH Corporation.

Wiring harnesses supplied are usually adequate for most

installations. Harnesses are loomed at the factory. All con-

nections are plug in type except for pump relay which has

ring terminal connections and the power supply for the panel.

That is a field connection made by the installers.

If lengthening or shortening the harness is necessary it is

suggested that all connections be soldered and protected

with shrink tube. If other connection devices are used they

must be sealed to prevent deteriation of the connection.

Grease-filled weather resistant crimp on butt connectors are

available .

Packard Connectors are marked with A & B for wire

connections. This cannot be mixed up. Maintain correct wire

size and color when altering harnesses.

Master Warning Light/Buzzer connections are done by the

installer. Route all wiring away from all heat sources and pro-

tect against sharp edges. Check that jacks can pivot properly

without cutting or stretching wire harnesses or connections.

All grounding connections are supplied by HWH Corporation

and all grounding should be done at the supplied ground stud.

(Refer to PUMP RELAY AND PANEL CONNECTION DIAGRAM).

Coat all exposed electrical connections (battery cable ends,

pump solenoid terminals, grounds, etc.) with a protective

sealant such as Kraylon 1307.

6. THE MASTER WARNING LIGHT/BUZZER:

Warning Light should be used with all systems. A buzzer must

be used with systems using straight acting jacks.The Master

Warning Light should be mounted in the dash in a location

highly visible to the driver. This light will warn the driver if

any of the jacks are down when the ignition is turned to "ON".

Drill a 1/2" hole at the desired location. Be sure to check for

wires or other devices behind the surface before drilling. When

installing the light itself, make sure the ignition is in the "OFF"

position. With the ignition on +12 can be present at the warn-

ing light.

When using a buzzer, the +12 power should come from the

"ON" side of the ignition switch. The power for the panel should

come from the "ACC" side of the ignition switch. (Refer to the

MASTER LIGHT/BUZZER CONNECTION DIAGRAM).

With all wiring complete, the light plate (100 Series System),

or cover plate (110 Series) may now be mounted.

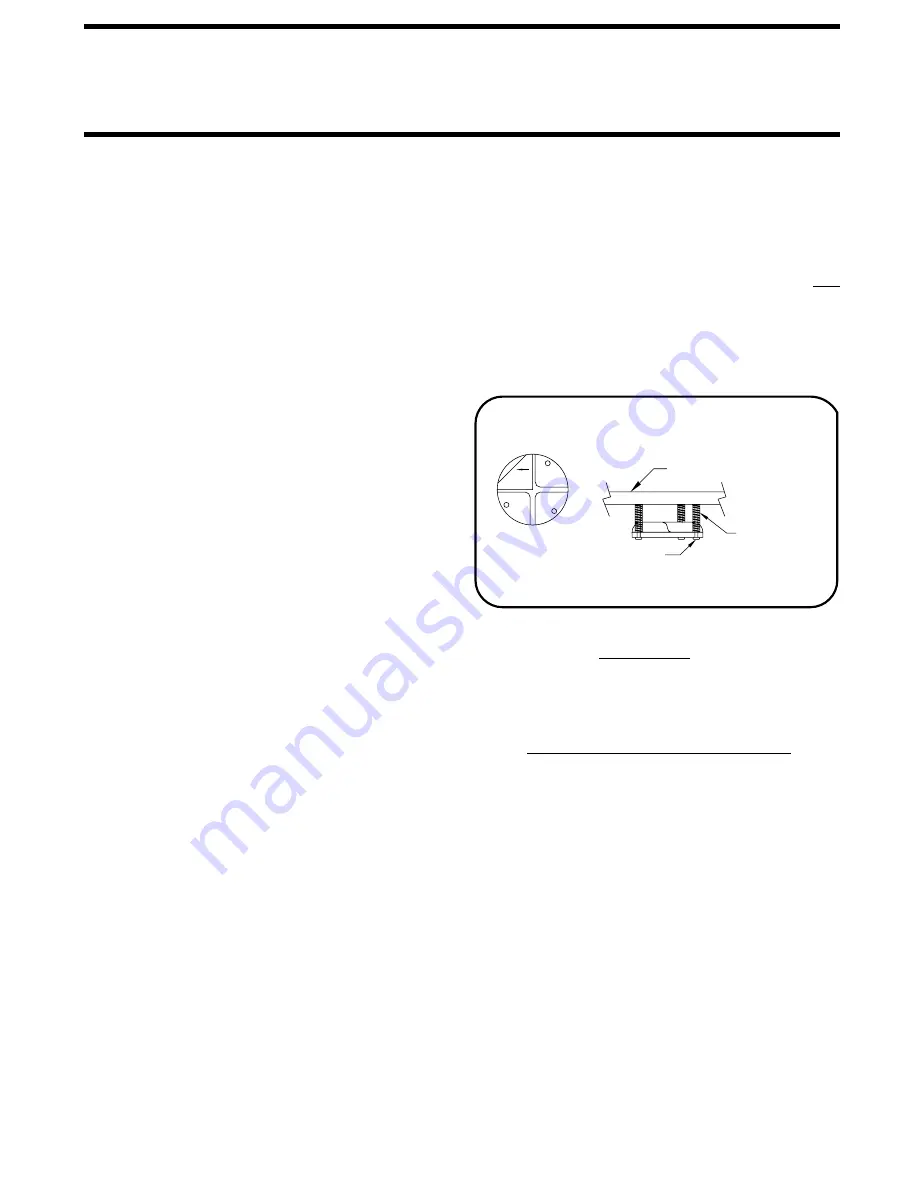

7. MOUNTING THE SENSING UNIT:

can be mounted above or below the surface as long as the

"This Side Up" sticker (FIGURE 8) is facing up and the "Rear"

arrow is pointing to the rear of the coach. The sensing unit

must be mounted to a solid surface that will not flex. Do NOT

mount the sensing unit near any heat-emitting items. Outside

of the frame rails is preferred. The sensing unit must be at

least 12" away from exhaust pipes or other high temperature

components, and must not be in line of sight from these high

temperature components.

A Master

8. FLUIDS: Use Mercon, Multipurpose or Dextron automatic

transmission fluid. DO NOT USE brake fluid or hydraulic

jack fluid. Use of these fluids can damage seals. The hydraulic

tank should be filled to within 1" from the top.

Air Dump - Optional

The air dump feature is used only on coaches with full air bag

suspension, not on coaches with spring suspensions and air

booster bags.

Most coaches have three height control valves; one for the

right rear air bag, one for the left rear air bag, and one for

the front two air bags, OR one for the two rear bags, one for

left front air bag, and one for the right front air bag.

An air dump solenoid valve must be teed into the air line be-

tween each height control valve and the air bag it controls.

(See the Air Line Connection Diagram).

On the 100 and the 110 Series, the air dump signal is on the

yellow wires coming from the control panel. There is one

connection at the front of the vehicle and one at the rear. A

Tee adaptor is supplied with the control system. This will con-

nect two dump valves to one harness connection at the front

or rear of the vehicle. (Refer to Electrical Connection Diagram

With Suspension Air Dump.)

COMPONENT INSTALLATION

NOTE:

The Level Sensing Unit

SURFACE

MOUNTING

BELOW THE SURFACE MOUNTING

SCREWS (3)

REAR

THIS

SIDE

STICKERS

ON TOP

UP

FIGURE 8

LEVEL SENSING UNIT

SPRINGS (3)