IGUP-RED-0309

4

LOCATION

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature and

humidity are maintained at or below 75°F and 55% rela-

tive humidity. DO NOT allow air conditioning, electric fans,

ovens, open doors or windows (etc.) to create air cur-

rents around the merchandiser, as this will impair its cor-

rect operation.

DO NOT place Self Contained versions

of this case, having the electric evapo-

rator pan, underneath or adjacent to

any flammable structure or structure

housing flammable merchandise!

UNCRATING THE STAND

Place the fixture as close to its permanent position as

possible. Remove the top of the crate. Detach the walls

from each other and remove from the skid. Unbolt the

case from the skid. The fixture can now be lifted off the

crate skid. Lift only at base of stand!

EXTERIOR LOADING

These models have not been structurally designed to sup-

port excessive external loading. Do not walk on their

tops; This could cause serious personal injury and dam-

age to the fixture.

SETTING AND JOINING

The sectional construction of these models enable them

to be joined in line to give the effect of one continuous

display. A joint trim kit is supplied with each joint.

Attention Installer!

Proper case joint sealing is extremely

important to prevent water leaks!

It is the contractor’s responsibility to install

case(s) according to local construction and

health codes.

LEVELING

IMPORTANT! It is imperative that cases be

leveled from front to back and side to side prior

to joining. A level case is necessary to insure

proper operation, water drainage, glass align-

ment, and operation of the hinges supporting

the glass. Leveling the case correctly will solve

most hinge operation problems.

NOTE: A. To avoid removing concrete flooring, begin

lineup

leveling from the highest point of the

store floor.

B. When wedges are involved in a lineup, set them

first.

All cases were leveled and joined prior to shipment to

insure the closest possible fit when cases are joined in the

field. When joining, use a carpenters level and shim legs

accordingly. Case must be raised correctly, under legs

where support is best, to prevent damage to case.

1. Check level of floor where cases are to be set.

Determine the highest point of the floor; cases will

be set off this point.

2. Set first case, and adjust legs over the highest part of

the floor so that case is level. Prevent damage – case

must be raised under leg or by use of 2x6 or 2x4 leg

brace. Remove side and back leg braces after case is

set.

3. Set second case as close as possible to the first case,

and level case to the first using the instructions in

step one.

4. Apply masking tape 1/8" in from end of case on

inside and outside rear mullion on both cases to be

joined.

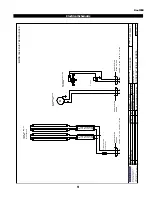

5. Apply liberal bead of case joint sealant (butyl) to

dotted area shown in (Fig.2, #1) of first case. Apply

heavy amount to cover entire shaded area.

DO NOT USE PERMAGUM!

6. Slide second case up to first case snugly. Then level

second case to the first case so the front bumper

and top fascia are even.

7. To compress silicone at joint, use two Jurgenson

wood clamps. Make sure case is level from front to

back and side to side on inside bulkheads at joint.

8. Bolt tops together behind llight, and close camlocks

usiong a 5/16" allen wrench. Camlocks are located in

the rear of the case below air discharge and be-

tween the front legs.

Do not use cam locks to pull cases together.

ENDS

Bolt the end(s) onto the case using the bolts provided in

the pre-drilled holes on the side(s) of the case.

D

O

N

OT

S

EAL

J

OINT

T

RIM

T

O

F

LOOR

!

Installation

Summary of Contents for Chino RED

Page 14: ...IGUP RED 0309 14...