IGUP-RED-0309

12

APPENDIX A. – Temperature Guidlines

The refrigerators should be operated according to Hussmann’s

published engineering specifications for entering air temperatures for

specific equipment applications. Table 1 shows the typical temperature

of the air entering the food zone one hour before the start of defrost

and one hour after defrost for various categories of refrigerators.

Refer to Appendix C for Field Evaluation Guidelines.

TABLE 1

Type of Refrigerator

Typical Entering

Air Temperature

I. OPEN DISPLAY

A. Non frozen:

1) Meat

28°F

2) Dairy/Deli

32°F

3) Produce

a. Processed

36°F

b. Unprocessed

45°F

B. Frozen

0°F

C. Ice Cream

-5°F

II. CLOSED DISPLAY

A. Non frozen:

1) Meat

34°F

2) Dairy/Deli

34°F

3) Produce

a. Processed

36°F

b. Unprocessed

45°F

B. Frozen

0°F

C. Ice Cream

-5°F

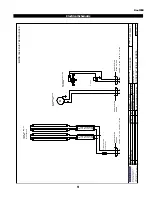

Single Deck

Multi Deck

ServiceCase

Reach-In

I. Open Display Styles

II. Closed Display Styles

APPENDIX B. – Application Recommendations

1.0 Temperature performance is critical for controlling bacteria

growth. Therefore, the following recommendations are included in

the standard. They are based on confirmed field experience over

many years.

1.1 The installer is responsible for following the installation instruc-

tions and recommendations provided by Hussmann for the

installation of each individual type refrigerator.

1.2 Refrigeration piping should be sized according to the equipment

manufacturer’s recommendations and installed in accordance with

normal refrigeration practices. Refrigeration piping should be

insulated according to Hussmann’s recommendations.

1.3 A clogged waste outlet blocks refrigeration. The installer is

responsible for the proper installation of the system which

dispenses condensate waste through an air gap into the building

indirect waste system.

1.4 The installer should perform a complete start-up evaluation prior to

the loading of food into the refrigerator, which includes such items as:

a) Initial temperature performance, Coils should be properly fed with

a refrigerant according to manufacturer’s recommendations.

b) Observation of outside influences such as drafts, radiant

heating from the ceiling and from lamps. Such influence should

be properly corrected or compensated for.

c) At the same time, checks should be made of the store dry-

bulb and wet-bulb temperatures to ascertain that they are

within the limits prescribed by Hussmann.

d) Complete start-up procedures should include checking through

a defrost to make certain of its adequate frequency and length

without substantially exceeding the actual needs. This should

include checking the electrical or refrigerant circuits to make

sure that defrosts are correctly programmed for all the

refrigerators connected to each refrigeration system.

e) Recording instruments should be used to check performance.

APPENDIX C. – Field Recommendations

Recommendations for field evaluating the performance of retail

food refrigerators

1.0 The most consistent indicator of display refrigerator performance

is temperature of the air entering the product zone (see

Appendix A). In practical use, the precise determination of return

air temperature is extremely difficult. Readings of return air

temperatures will be variable and results will be inconsistent. The

product temperature alone is not an indicator of refrigerator

performance.

NOTE

: Public Health will use the temperature of the product in

determining if the refrigerator will be allowed to display potentially

hazardous food. For the purpose of this evaluation, product

temperature above the FDA Food Code 1993 temperature for

potentially hazardous food will be the first indication that an

evaluation should be performed. It is expected that all refrigerators

will keep food at the FDA Food Code 1993 temperature for potentially

hazardous food.

1.1 The following recommendations are made for the purpose of

arriving at easily taken and understood data which, coupled with

other observations, may be used to determined whether a display

refrigerator is working as intended:

a) INSTRUMENT – A stainless steel stem-type thermometer is

recommended and it should have a dial a minimum of 1 inch

internal diameter. A test thermometer scaled only in Celsius or

dually scaled in Celsius and Fahrenheit shall be accurate to

Appendices

Summary of Contents for Chino RED

Page 14: ...IGUP RED 0309 14...