Rev.0210

5

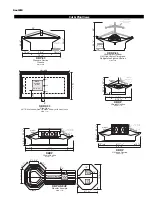

SETTING AND JOINING

The sectional construction of these models enable them

to be joined in line to give the effect of one continuous

display. A joint trim kit is supplied with each joint.

LEVELING

IMPORTANT! IT IS IMPERATIVE THAT

CASES BE LEVELED FROM FRONT TO

BACK AND SIDE TO SIDE PRIOR TO JOIN-

ING. A LEVEL CASE IS NECESSARY TO IN-

SURE PROPER OPERATION, WATER

DRAINAGE, GLASS ALIGNMENT, AND OP-

ERATION OF THE HINGES SUPPORTING

THE GLASS. LEVELING THE CASE COR-

RECTLY WILL SOLVE MOST HINGE OPERA-

TION PROBLEMS.

NOTE: A. To avoid removing concrete flooring, begin lineup

leveling from the highest point of the store floor.

B. When wedges are involved in a lineup, set them first.

All cases were leveled and joined prior to shipment to

insure the closest possible fit when cases are joined in the

field. When joining, use a carpenters level and shim legs

accordingly. Case must be raised correctly, under legs

where support is best, to prevent damage to case.

1. Check level of floor where cases are to be set.

Determine the highest point of the floor; cases will

be set off this point.

2. Set first case, and adjust legs over the highest part of

the floor so that case is level. Prevent damage – case

must be raised under leg or by use of 2x6 or 2x4 leg

brace. Remove side and back leg braces after case is

set.

3. Set second case as close as possible to the first case,

and level case to the first using the instructions in

step one.

4. Apply masking tape 1/8" in from end of case on

inside and outside rear mullion on both cases to be

joined.

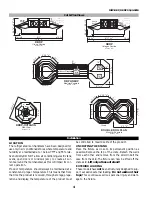

5. Apply liberal bead of case joint sealant (butyl) to

dotted area shown in (Fig.2, #1) of first case. Apply

heavy amount to cover entire shaded area.

DO NOT USE PERMAGUM!

It is the contractor’s responsibility to install

case(s) according to local construction and

health codes.

6. Slide second case up to first case snugly. Then level

second case to the first case so glass front, bumper

and top are flush.

7. Apply bead of silicone to side of either half of case (if

case is built in two pieces). Also apply silicone to

seam between overhead light tubes.

8. Slide second half up to first case snugly. To compress

silicone at joint, use two Jurgenson wood clamps to

pull the inside of the bulkheads together. Make sure

case is level from front to back and side to side at

joint. DO NOT USE BOLTS TO DRAW CASES UP

TIGHT! DAMAGE MAY OCCUR!6. Make sure cases

are tight and bolted together in all locations (see

diagram next page). Remove clamps. Cleanup excess

silicone.

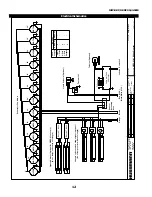

9. There may be an interlock system built into the tower,

depending on the height of it. Joining involves a

number of bolts, again dependent on the height.

10. Attach joint trim pieces, that will hide the loose joint

where the case halves come together.

11.Connect case to field electrical, refrigeration, and

pipe to floor sink.

12. Install body covers.

13. Attach cart bumper, if applicable.

SPLASH GUARD

After cases have been leveled and joined, and refrigera-

tion, electrical, and wasted piping work completed, install

the splashguards. Fasten along the top edge, or center, with

#10 X 3/3" sheet metal screws.

D

O

N

OT

S

EAL

J

OINT

T

RIM

T

O

F

LOOR

!

Installation (cont.)

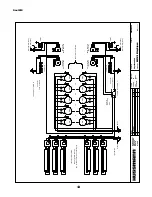

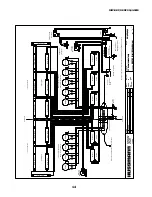

BOLT LOCATIONS

SEALANT APPLICATION

Summary of Contents for Chino DBP Series

Page 18: ...IGIP DBP DBRP 01 03 0210 18...