6

49

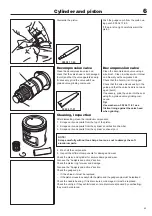

Cylinder and piston

Service tips

Wear tolerances

When the surface coating is worn

and aluminium appears.

Max. 1.0 mm with the piston ring

inserted in the lower part of the

cylinder.

Max. 1.6 mm. Clean the groove be-

fore checking the measurement.

Max. 0.15 mm. Clean the groove

before checking the measure-

ment.

Piston ring play

Piston ring groove

Piston ring gap

Cylinder

bore

Defect:

Broken cooling

fi

ns, damaged threads or sheared bolts by

the exhaust port.

Seizure marks in the cylinder bore (especially by the ex-

haust port).

Surface coating in the cylinder bore worn out (primarily at

the top of the cylinder).

The piston shows signs of seizure score marks.

Piston ring burnt in its groove.

Bolts much too tight in the aluminium material.

Action:

In severe cases – replace the cylinder.

Repair the threads using Heli-Coil.

Polish the damaged area using a

fi

ne grade emery cloth so

that the coating of aluminium disappears.

With deep seizure score marks the piston and cylinder

should be replaced.

Replace the cylinder and piston.

Carefully polish the damaged area using a

fi

ne

fi

le of

fi

ne

grade emery cloth. Before the piston is re

fi

tted the cylinder

should be polished as above. With deep score marks the

piston and cylinder should be replaced.

Carefully loosen the piston rings and clean the groove well

before re

fi

tting. Carbon deposits in the groove impair the

important heat transfer between the piston and cylinder.

NOTE!

Be careful with the lower edge of the piston ring

groove. If this is damaged, or if carbon deposits

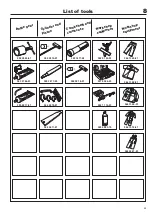

remain, the compression pressure can leak through.

Summary of Contents for 345FR

Page 1: ...Workshop manual English 545RX 545FR 545FX 545FXT 545RX 545RXT 345FR ...

Page 2: ......

Page 16: ...2 14 Electrical system ...

Page 52: ...6 50 Cylinder and piston ...

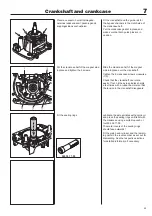

Page 58: ...7 56 Crankshaft and crankcase ...

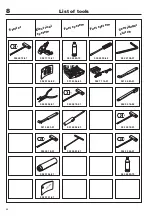

Page 62: ...8 60 List of tools ...

Page 65: ......

Page 66: ...2012W12 115 48 40 26 ...