5

39

502 50 65-01

503 97 64-01

Angle gear

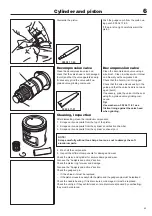

Remove the lubricant top-up plug.

Warm the gearbox and knock it against a

wooden block so that the input axle falls

out.

Remove the lubricant top-up plug and

warm the entire gearbox using a hot air

gun to about 150°C.

Knock the gearbox against a wooden

block so that the input axle and bearing

fall out.

NOTE!

The input axle with pinion must be

dismantled fi rst.

Remove the output axle.

Then remove the output axle and bear-

ings, while the gearbox is still warm.

Use puller no. 502 50 65-01.

Assembly

Replace damaged parts.

Assemble the angle gear in the reverse

order as set out for dismantling.

Fit the bearings on their respective axles.

It is easier if the bearings are heated to

approx. 100°C.

NOTE!

Do not forget the circlip holding the

bearing on the input axle. Make sure

the bearings bottom in their seats.

Heat the gearbox to approx. 150°C and

fi rst lift the output axle in position and then

the input axle. Make sure the bearings

bottom in their seats.

Mount the circlips and make sure they lie

correctly in their grooves.

Rotate the axles and check that they

rotate easily without a tendency for the

cogwheels to seize.

Fill the gearbox with special grease no.

503 97 64-01. Wipe any excess grease

from the joint between the shaft and the

angle gear before the gear is fi tted to pre-

vent it from turning around the shaft.

Summary of Contents for 345FR

Page 1: ...Workshop manual English 545RX 545FR 545FX 545FXT 545RX 545RXT 345FR ...

Page 2: ......

Page 16: ...2 14 Electrical system ...

Page 52: ...6 50 Cylinder and piston ...

Page 58: ...7 56 Crankshaft and crankcase ...

Page 62: ...8 60 List of tools ...

Page 65: ......

Page 66: ...2012W12 115 48 40 26 ...