©

2008 by Huchez Treuils S.A.S.

Original manual

10

FR

Reproduction prohibited

8.6. Unwinding the cable

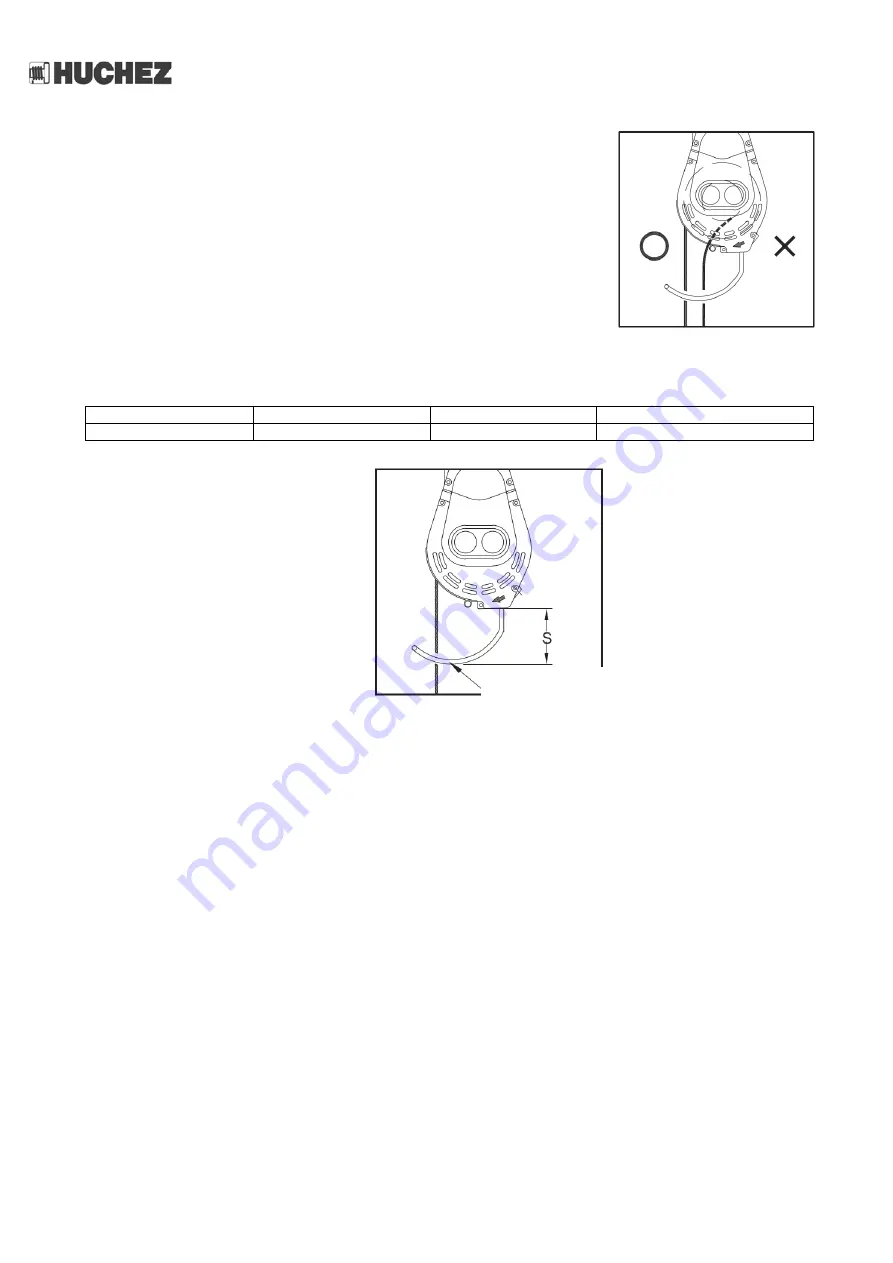

When the cable is fully unwound, it changes position and goes from the

O

position to the

X

position. It is very dangerous to use it in this position.

When the safety feature has stopped the movement, press the button

to return it to the

O

position.

8.7. Adjusting the limit switch

A special mechanism automatically stops the winding in the limit switch.

When the hook stopper touches the limit switch fork, the appliance

stops automatically.

If the limit switch fork is set too close to the winch, the fork or frame

may be damaged. For added security, turn the adjusting screw to space

the fork from the frame as shown. A distance (S) between the limit

switch fork and the cover is suggested below.

Model

PALANBOX 80

PALANBOX 160

PALANBOX 230

Distance

80-100 mm

70-90 mm

70-90 mm

8.8. Braking

The braking system consists of a mechanical brake and an electronic brake. A ratio of 1.5% of cable

length to reel per minute is tolerated between the time the brake is activated and a complete stop.

The no-load winding speed is 1.5 to 1.8 times the nominal speed at nominal load.

8.9. Carbon brushes and drain

The service life of carbon brushes is 150 hours. They should be replaced when they reach 7.5mm in

length. Anything else could seriously damage the motor.

Remove the screw from the brush holder using a screwdriver and replace the carbon brush. Each time

the brush is replaced, the reducer must be lubricated with 100 cm3 of NLGI grade O oil.

Remove the drain bolt using a hex wrench and drain.

Limit switch fork