Chengdu Huayuan Electric Equipment Co.,Ltd

LGK-40/63/100IGBT OPERATOR’S MANUAL

8

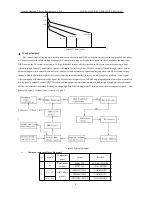

External Characteristic

◆

Work principles

The control circuit of cutting machine adopts advanced electronic part IGBT as the main inverter switch component. Three-phase

AC power is converted to 20KHz high-frequency DC current after being rectified by three phase rectifier. Then under the function of

IGBT inverter the DC current is inverted to AC high frequency current, which is inverted to DC current after experiencing voltage

reduction in high frequency transformer, current rectifying in fast recovery diode. This DC current is filtered through reactor, and the

output cutting current is obtained. Control circuit can control output current by controlling driven pulse width. The real time cutting

current, which is obtained through current sensor connected to output terminal in series, is used as negative feedback control signal.

After comparing with current adjusting signal, the negative control signal is sent to PWM adjusting integrated circuit, then a controlled

driving pulse is output to control IGBT. Thereby a constant output current can be maintained, and a steep dropping & constant current

external characteristic is obtained. Striking arc adopts high-frequency striking model. The main circuit refers to appendix figure1

,

and

principle diagram of control circuit is shown as figure 2.

Figure 2 Principle diagram

Common component list as diagram 1

No.

Symbol

Components

name

Model

Remark

1

V1

Three phase

rectifier

MDS35-14

LGK-40

、

63IGBT

MDS75-12

LGK-100IGBT

2

V2

~

V5

IGBT single

module

IKW25N120T2

LGK-40IGBT

IKW40N120T2

LGK-63IGBT

V2

、

V3

GD75HFV120C2S

LGK-100IGBT

I

270V

240V

40A

U

63A/105.2V

40A/96V

63A

296V

100A

100A/120V

Summary of Contents for LGK-63/100MA

Page 18: ......