Chengdu Huayuan Electric Equipment Co.,Ltd

LGK-40/63/100IGBT OPERATOR’S MANUAL

12

front-below panel.

7.

Connection of cutting ground wire

Connect the fast connector of cutting ground wire with the outlet marked with Cutting Ground Wire on the front-below panel and

screw down it clockwise. The other end of the cutting ground wire is connected to workpiece firmly.

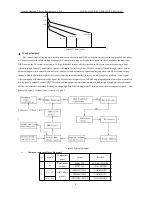

Operation method

1. Security notes

Turn on the power switch after installation and connection. Then the power indicator lamp is ON.

Gas control switch switches to Check air. Adjust the pressure Adjusting knob of gas filter on the back panel to make the pressure

and flux fit cutting condition. After adjusting, set the switch to Cutting position.

Set the cutting current to required value.

Let the nozzle axes plumb the workpiece and cling to it firmly, press down the torch switch and start to cut by striking arc from

the edge of workpiece. To punch hole by plasma arc in the middle of workpiece is not proposed, because the nozzle would be

damaged easily. It is better to punch a hole in the arc-striking position first, then strike arc from the edge of the hole.

If want to stop cutting, please loosen the torch switch, cutting arc extinguishes, and gas supply will stop in 5-8S automatically.

Notes

:

Operation strictly accordant with the following steps

Notice

Electric shock may

hurt or even kill

man.

Cutting may cause fire or explosion

Splashes may ignite flammable materials nearby.

Those materials should be 10m away from the

working place.

Shut off the power during connection

Do not touch the conducted parts

Fume & dust is harmful.

Do not breathe in the fume and dust

caused by cutting

Clean up the oil spot on work piece.

Keep fresh air in working place

Fume extraction equipment should

be prepared.

Arc may hurt your eyes and skin.

Strong arc may hurt your eyes.

Ultraviolet radiation generated by arc may hurt

skin and eyes. Please wear shielded guard when

cutting.

Overheated part may hurt

your skin.

Do not touch the overheated part on

the work piece.

Do not touch hot cable or torch just

by hands.

Fast moving thing may injure you.

Do not put your hands or other things into the

fan shield.

Cover the opened case shell well during cutting

operation.

In case of injury for your skin and eyes, please wear

required guards according to Labor Security and Hygiene

rules. Electrode and nozzle should be replaced only after

the cutter is power off.

Operation should proceed according to related Labor and

Security regulations.

Summary of Contents for LGK-63/100MA

Page 18: ......