20

9, Common faults and eliminating methods

If there some problems that can not be judged or solved, please do not hesitate to

contact our company to get some technical assistance. Please do not repair or open the

machine arbitrarily. There is high voltage after cutting power for 10 minutes, only qualified

electrician can operate!

Common faults and eliminating methods: (see below sheet)

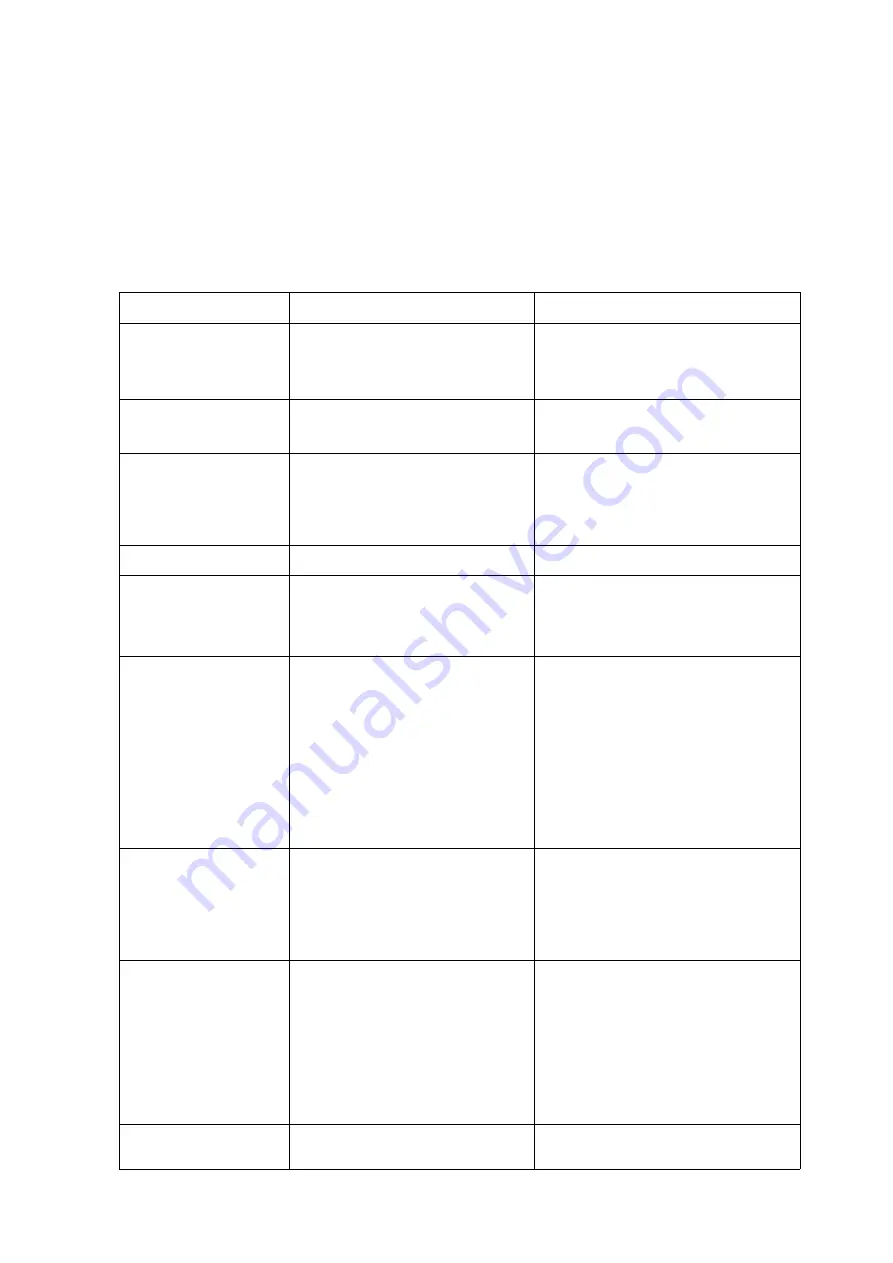

Table 9 Common faults and eliminating methods

Faults

Reasons

Eliminating methods

1

.

Put power on, the power

indicator do not light,

digital display meter don't

work

1.Open phase of three phase power;

2.The power switch is old and damaged;

3.The 1.5A fuse of power control is melt;

1.Check the three phase power switch;

2.Replace power switch;

3.Replace the fuse;

2

.

Welding machine do not

work, under

1

.

Open phase on three phase power;

2

.

Under voltage on three phase power;

Check three phase supply power, make sure

supply voltage fit the required voltage;

3

.

Welding machine do not

work, the over-heating

indicator lights

1.The environment temperature is too

high;

2.There is something wrong with the

cooling fan;

3.The temperature relay is damaged;

1.Make welding machine rest for a moment;

2.Check the power of cooling fan or replace

cooling fan;

3.Replace the temperature relay;

Faults

Reasons

Eliminating methods

4. There is wire feeding, but

no current spark, or there is

noise in machine

1.The fast recovery diode is damaged;

2.IGBT is damaged;

3.Circuit or other components are

damaged;

1.Check and replace the damaged fast

recovery diode;

2.Replace IGBT or PCB;

3.Check and replace the damaged parts;

5

.

Press torch switch, wire

wheel moves, but there is

no wire sending out from

torch, or the wire feeding is

unstable

1.The wire wheel is not tighten;

2.The diameter of wire slot is not same as

electrode wire;

3.The contact tip is blocked by spatter;

4.The wire reel slog is abraded;

5.The wire feeding pipe of torch is

blocked;

6.The torch cable is excessive bended;

1.Fasten the wire wheel;

2.Replace wire slot;

3.Eliminate the spatter on contact tip;

4.Replace wire feeding wheel;

5.Clean the dirty or dust in wire feeding pipe

by dry compressed air or replace it with a

new one;

6.Make the bending diameter of torch cable

larger than 300mm;

6

.

Press torch switch, the

wire feeding wheel do not

move or there is no no-load

voltage

1

.

Control cable of wire feeder is

damaged;

2

.

Open circuit on control cable of

welding torch switch;

3

.

The PCB is damaged;

4. The wire feeding motor is damaged;

1

.

Check the control cable;

2

.

Repair the wire feeding motor or replace it

with a new one;

3

.

4. Repair or replace motor;

5. Repair or replace PCB;

7

.

There are too many air

holes on welding seam;

1.CO

2

gas is not pure;

2.The gas flow is not enough;

3.There is grease dirt or rust on welding

seam;

4.The wind in the welding place is too

heavy;

5.CO

2

gas circuit is blocked or blab;

6.Gas valve doen`t actuate;

7.Deformation on nozzle;

1.Use high purity CO

2

gas;

2.Adjust the gas flow;

3.Eliminate the grease dirt or rust on welding

seam;

4.Do something to reduce the wind in

welding place;

5.Check the gas circuit, dredge it or block it;

6.Replace the nozzle of welding torch;

8. Current and voltage can

not be adjusted

1.The potentiometer of current and

voltage is damaged;

1.Replace potentiometer;

2.Repair or replace the PCB;