Site Requirements

3

To ensure personal and equipment safety, observe all the safety

precautions on the equipmentand in this document.

and and items do not cover all the safety precautions and

are only supplementary to the safety precautions.

The device needs to be installed in a clean, dry, well ventilated, and

temperature-controllable standard equipment room. In addition, the

equipment room must be free from leaking or dripping water, heavy

dew, and condensing.

Dustproof measures must be taken in the installation site. This is

because dust will cause electrostatic discharges on the device and

affect connections of metal connectors and joints, shortening the

service life of the device and even resulting in device failures.

The installation site must be free from acidic, alkaline, and other

types of corrosive gases.

The device that is operating may cause radio interference. If this is the

case, relevant measures may be needed to reduce the interference.

Generally, devices such as wireless antennas should not be installed in

the equipment room. If such devices must be installed indoors, ensure

that the electromagnetic environment meets relevant requirements or

take necessary electromagnetic shielding measures.

The device to be installed must be used indoors. To ensure normal

operation and long service life of the device, the following requirements

must be met:

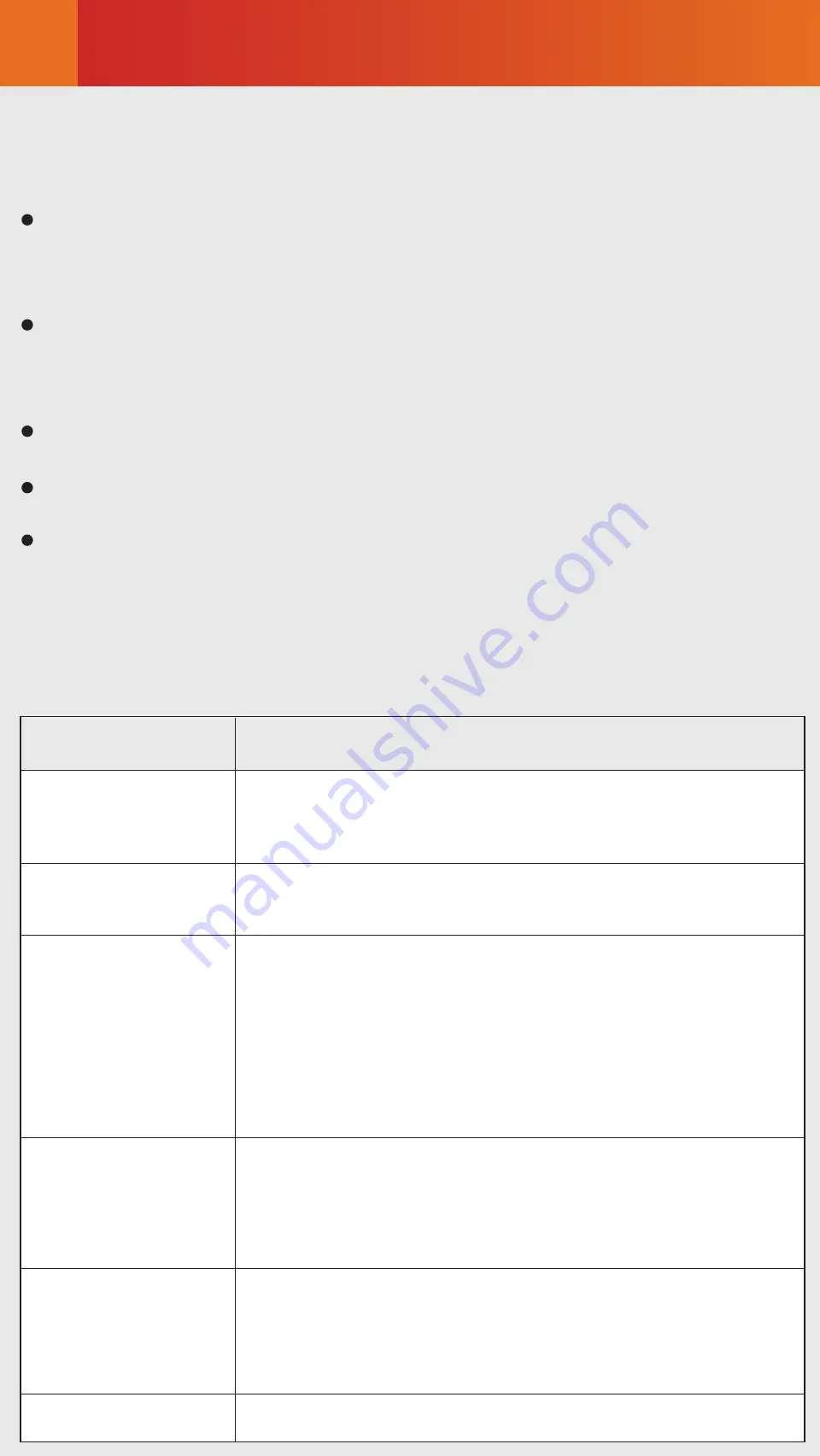

The temperature and humidity in the installation site must meet device

requirements described in the following table.

Long-term operating

temperature [°C]

Relative operating

humidity [RH]

DC:

PTN devices: –20°C to +60°C

Other devices: –40°C to +65°C

AC:

–20°C to +55°C

≤ 4000 m (For the altitude in the range of 1800 m

to 4000 m, the operating temperature of the device

decreases by 1°C every time the altitude increases

by 220 m.)

Item

Requirements

Storage temperature

[°C]

–40°C to +70°C

Relative storage

humidity [RH]

Long-term operating

altitude [m]

Storage altitude [m] < 5000 m

ATN 980C:

Long-term: 5% to 95% RH,

non-condensing Short-term: N/A

NetEngine 8000 M8/PTN 6900-2-M8C:

Long-term: 5% to 85% RH, non-condensing

Short-term: 5% to 95% RH, non-condensing

OptiX PTN 980/980B:

Long-term: 10% to 90% RH,

non-condensing Short-term: N/A

ATN 980C:

5% to 100% RH, non-condensing

NetEngine 8000 M8/PTN 6900-2-M8C:

5% to 95% RH, non-condensing

OptiX PTN 980/980B:

10% to 100% RH, non-condensing