MANUAL

HK2 – HK4 25-08-2014

Page

19

3

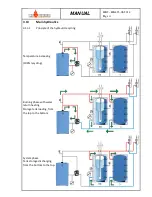

Installation instructions

3.1

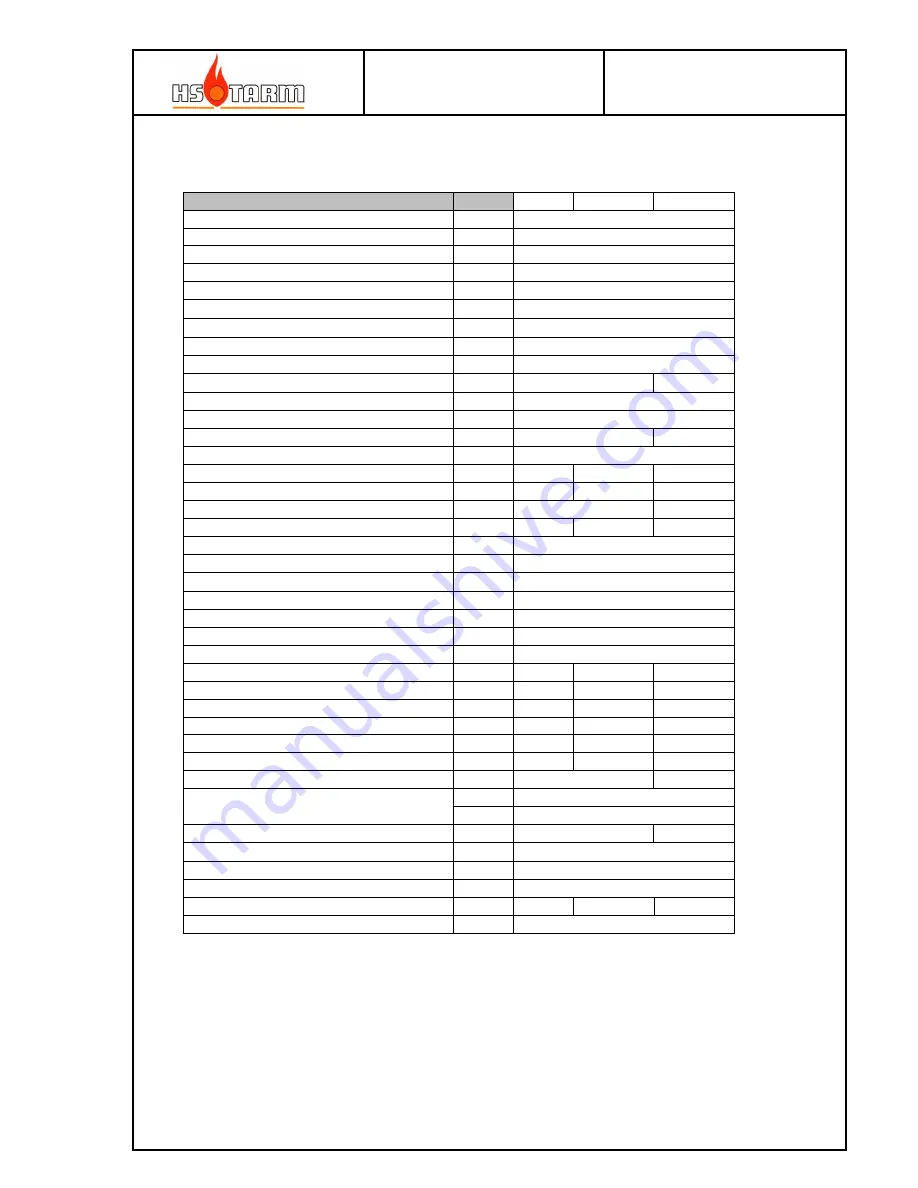

Technical data

See dimensional drawings next pages.

HK2

HK3

HK4

(1) Flow connection

"

1

(2) Return connection

"

1

Power supply

Volt

230

(3) Soot hatch

-

X

(4) Boiler drainage

"

1/2

(5)

∅

ext. flue gas pipe

mm

129

(6) Fan

∅

mm

180

Flue gas sensor pocket

mm

7

(7) Cooling coil hole diameter

"

1

Cooling coil length

mm

380

500

(8) Safety valve sensor placement

"

1/2

Stud for boiler water side sensor pocket

"

1/2

Nominal power

kW

32

50

Wood log chamber length

mm

540

Comb. period hard wood

h 3.5 – 4.0

4.5 – 5.5

4.0 – 5.0

Comb. period soft wood

h 2.5 – 3.5

3.5 – 4.5

3.0 – 4.0

Loading door : w. / h.

mm

250/340

330/420

Wood log chamber volume (net)

l

110

150

200

Wood logs length - max

cm

50

∅

hard wood max diameter

cm

10-15

∅

soft wood max diameter

cm

10-15

Max service pressure

bar

3.0

Boiler production test pressure

bar

4.5

Cooling coil test pressure

bar

25

Max operating temperature

°C

100

Total empty weight

kg

505

615

822

Water capacity

l

120

140

270

Minimum storage tank volume

l

1250

1750

2250

Dusts 10 % O

2

mg/m

3

45

30

<60

CO 10 % O

2

mg/m

3

677

612

<700

OGC 10 % O

2

mg/m

3

28

28

<30

Nominal flue gas temperature

°C

130

<160

Minimum draught needed

mm WC

1-1,5

Pa

10-15

Mass flow of flue gas

g/s

20

33

Pressure loss

∆

T 20°C

mmWC

3,5

Pressure loss

∆

T 10°C

mmWC

14

Electric consumption

W

<70

Efficiency

%

91.6

92,7

>90

Boiler class EN 303.5 2012

Class

5

Summary of Contents for HK2

Page 27: ...MANUAL HK2 HK4 25 08 2014 Page 27 3 8 Electrical connections ...

Page 33: ...MANUAL HK2 HK4 25 08 2014 Page 33 No text ...

Page 34: ...MANUAL HK2 HK4 25 08 2014 Page 34 No text ...

Page 35: ...MANUAL HK2 HK4 25 08 2014 Page 35 No text ...

Page 36: ...MANUAL HK2 HK4 25 08 2014 Page 36 Rev 02 010914 ...