Item

Description

1

Left bezel ear

2

NVMe drives

3

Right bezel ear

4

Chassis serial label pull tab

5

Non-removable bezel blanks

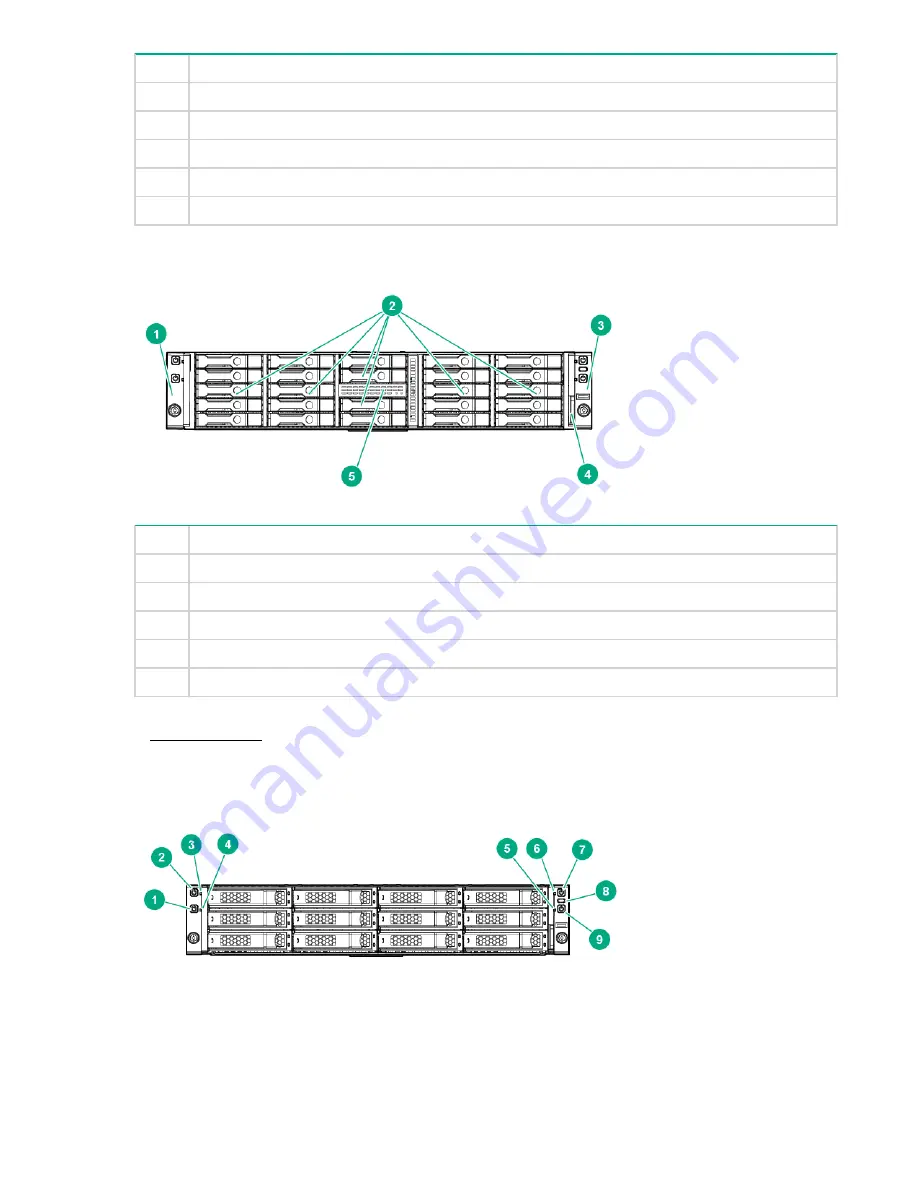

HPE Apollo r2800 Gen10 Chassis (24 SFF model with storage expander backplane)

Item

Description

1

Left bezel ear

2

SFF hot-plug drives

3

Right bezel ear

4

Chassis serial label pull tab

5

Expander daughter module with power LED

1

1

When the LEDs described in this table flash simultaneously, a power fault has occurred. For more information, see

Front panel LEDs

.

Front panel LEDs

14

Front panel LEDs