CAUTION:

To prevent the heat sink from tilting to one side

during installation/removal, turn each screw a couple of turns,

alternatively between both of them, and then apply the final

torque. Do not over tighten the spring loaded screws to prevent

them from breaking off. A maximum torque of 4.5 inch-lb is set

for each screw.

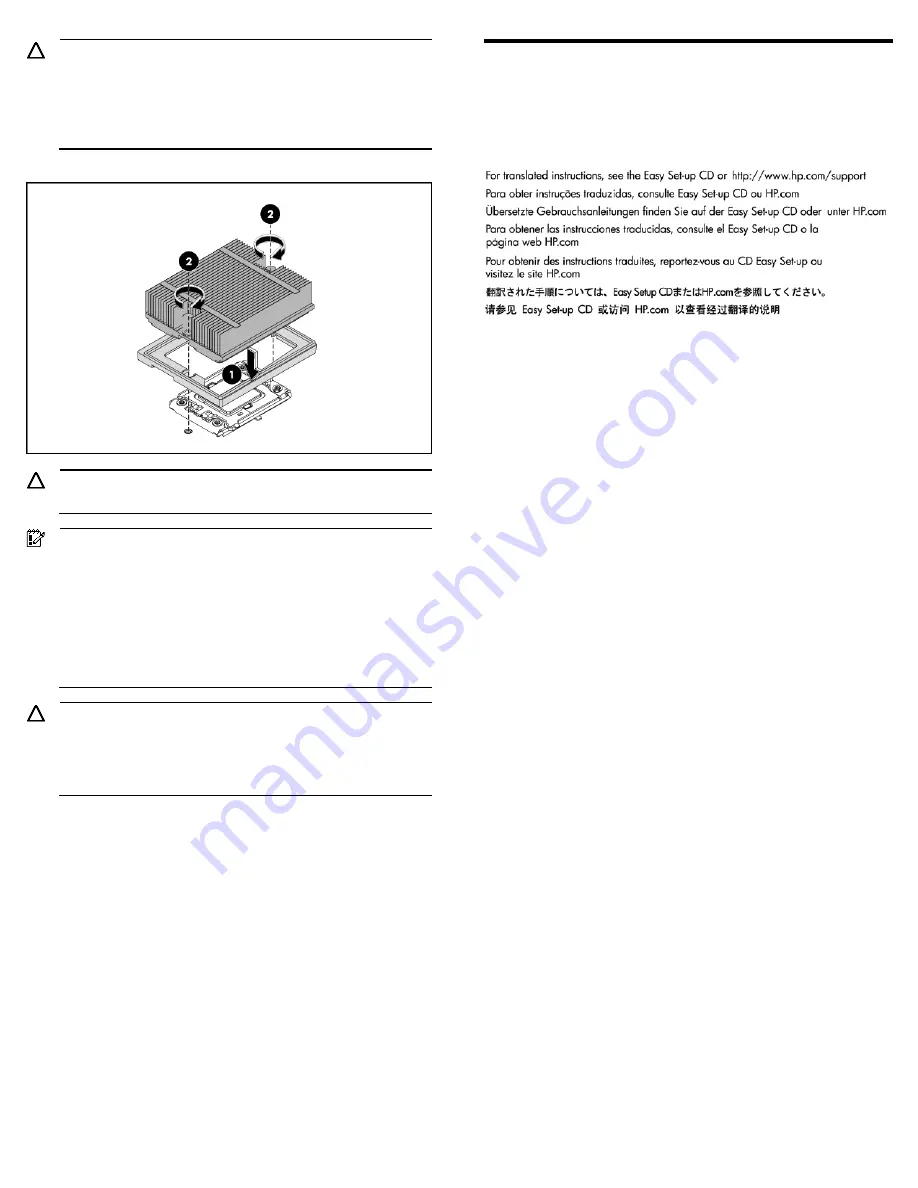

Figure 14

Installing the heat sink assembly

CAUTION:

Be sure that the heat sink sits squarely on the processor,

or overheating and damage to the processor may occur.

IMPORTANT:

If the heat sink has been removed for any reason,

it is critical that you apply more thermal interface material to the

integrated heat spreader on the processor to ensure proper

thermal bonding between the processor and the heat sink.

Clean the contact surface of both the processor and heat sink

with an alcohol pad, then re-apply an HP-approved thermal

interface material before reinstalling the processor. Use a

pattern of five dots when applying the thermal interface

material—one dot in the center, and one dot at each corner.

CAUTION:

To prevent the heat sink from tilting to one side

during installation removal procedures, use a diagonally

opposite pattern (an “X” pattern) when tightening the four

spring-loaded screws. Do not over tighten the heat sink’s

spring-loaded screws to prevent them from breaking off.

Additional Documentation

For additional documentation, refer to HP ProLiant DL170h G6 Easy

Set-up CD. You can also access additional information and

documentation from the HP external website, either by connecting

directly or through the Easy Set-up CD.