Removal and replacement procedures 65

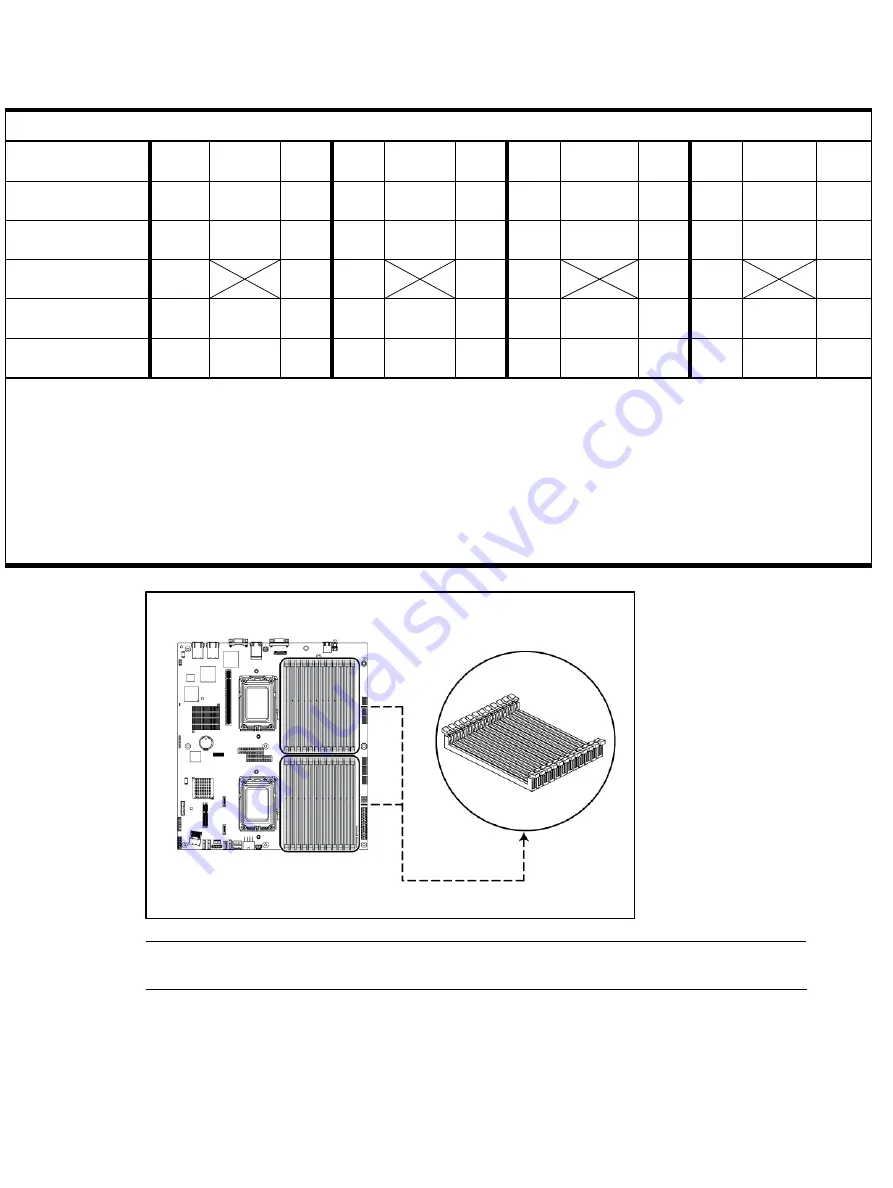

Memory module population order

Processor memory

socket

1

2

3

4

5

6

7

8

9

10

11

12

Rank support per

memory socket

SR/DR SR/DR/

GR

SR/D

R

SR/D

R

SR/DR/

GR

SR/D

R

SR/D

R

SR/DR/G

R

SR/D

R

SR/D

R

SR/DR/

GR

SR/DR

RDIMM Population

order without QR

A

1

E

C

K

G

B

J

F

D

L

H

UDIMM Population

order without QR

A

E

C

G

B

F

D

H

Population order with

QR along with SR/DR

E

A

1

G

C

K

F

B

J

H

D

L

Processor memory

bank number

1

3

2

1

3

2

1

3

2

1

3

2

NOTES:

SR = Single Rank, DR = Dual Rank, QR = Quad Rank.

Population rules must be followed for both processors.

Memory modules may be populated one at a time per processor, but populating two at a time per processor provides better performance.

Memory modules should be populated four at a time per processor for best performance.

Memory modules within a memory bank must be identical for best performance.

Quad Rank memory module can only be installed in memory sockets 2, 5, 8, and 11.

For more information on memory configurations, see the server user guide located on the Documentation CD or the HP Support website

(http://www.hp.com/support).

Figure 45

DIMM Slots

NOTE:

Before installing the memory, remove the air baffle first. For a detailed procedure, see

the ”Processor” section in this chapter.

Summary of Contents for ProLiant DL165 G7

Page 12: ...Customer self repair 12 ...

Page 13: ...Customer self repair 13 ...

Page 14: ...Customer self repair 14 ...

Page 15: ...Customer self repair 15 ...

Page 20: ...Illustrated parts catalog 20 ...

Page 60: ...Removal and replacement procedures 60 7 Engage the load lever ...

Page 92: ...Removal and replacement procedures 92 Figure 89 Reinstalling the System Fan ...