4

Table 1 Extension Cord Reference Chart

Unpacking Your New Portable Magnetic Drill

1. Open shipping carton and remove the literature and

hardare packages.

2. Read and follow all Instructions before attempting

to operate your new Magnetic Drill.

3. Complete and mail the Product Registration Card

NOW. It is important that Hougen Manufacturing, Inc.

have a record of product ownership.

4. Open hardware package and check contents.

10565 1/8” Allen Wrench for Gib Adjustment

10569 Feed handles (3)

10570 Feed handle knobs (3)

10727 3/16” Allen Wrench for reversing feed handle.

10730 Safety Chain

10779 7/32” Allen Wrench for cutter installation

13013 5/32” Allen Wrench for arbor installation and

microswitch adjustment

5. Using the handle of the Magnetic Drill, lift unit out of

the shipping case.

6. Remove all packing and securing material from the

drill unit.

7. Screw the three Knobs (10570) onto the three feed

handles (10569) and then screw the handles into the

hub .

8. Your Magnetic Drill was factory adjusted prior to shipping.

Check to make sure that all gib adjustment screws,

motor mount screws, front support bracket screws, and

magnet mounting screws are snug and have not vibrated

loose in transit.

9. Your New Magnetic Drill comes complete with arbor

mounted. The 3/4” diameter arbor bore fits all 3/4” -

shank “12000-Series” Rotabroach Cutters. A 1/2”

diameter boreArbor Adapter (10851), for mounting1/2”

shank “12,000-Series” Rotabroach Cutters, is optional.

Recommended cutting capacity when using “12,000-Series” Rotabroach Cutters-

Power Feed Mode

Manual Feed Mode

2” diameter maximum - 1” depth of cut

2-1/16” diameter maximum - 1” or 2” depth of cut

1-1/2” diameter maximum - 2” depth of cut

2” diameter maximum - 3” depth of cut

1-1/16” diameter maximum - 3” depth of cut

Actual cutting capacity may vary based on application. Feed setting chart on panel is recommended starting

point for diameter range. Adjustments may be needed for optimum cutting performance

Cutting Capacity

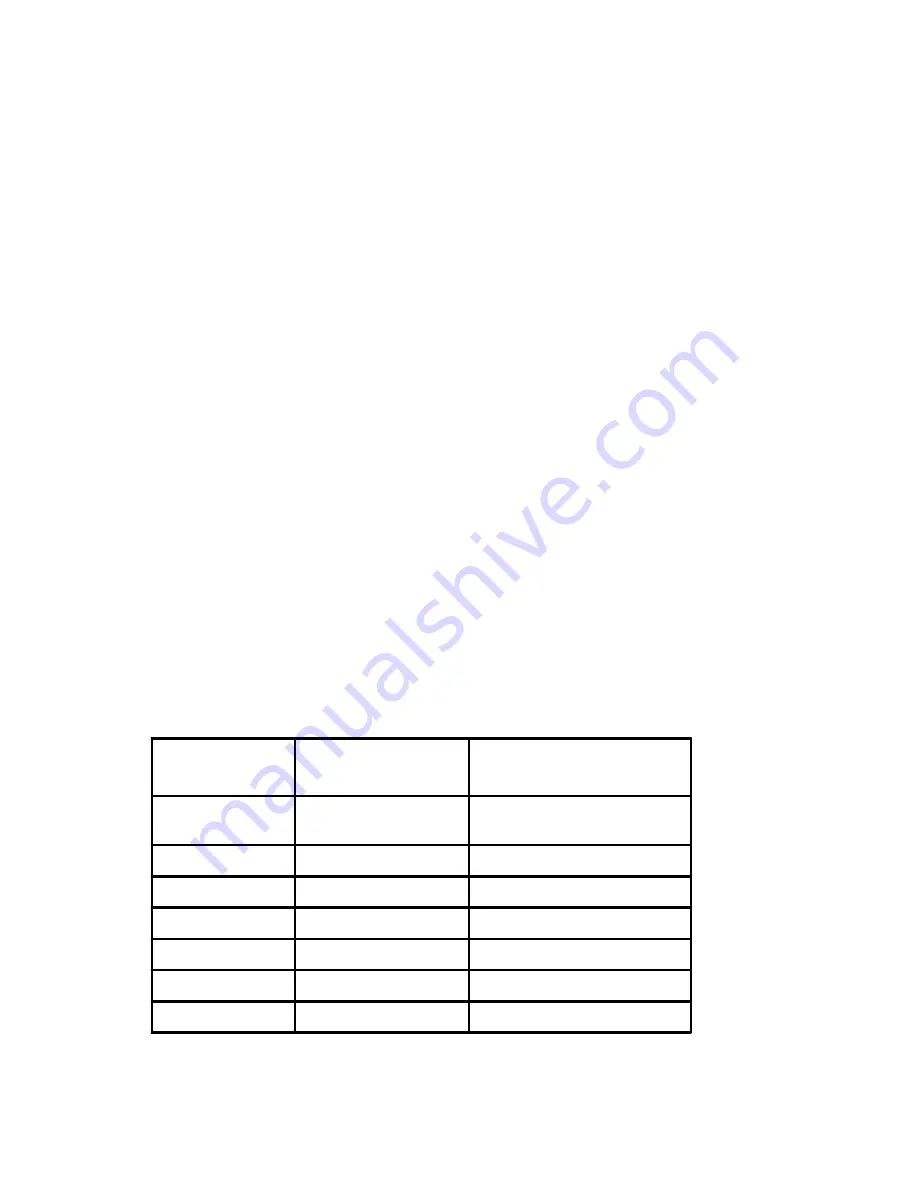

Length of Cord,

Feet

Recommended Wire

Gauge

Recommended Wire Gauge

115V Motor

10-12 Amps

230V Motor

5-6 Amps

Up to 25

16

18

26-50

14

18

51-100

10

16

101-200

8

14

201-300

6

12

301-500

4

10

Summary of Contents for 10925

Page 10: ...10 POWER FEED GEAR MOTOR...

Page 14: ...14 10925 10926 Power Feed Assembly...

Page 15: ...10925 10926 Mechanical Breakdown 15...

Page 16: ...16 Electrical Panel Layout Diagram...