16

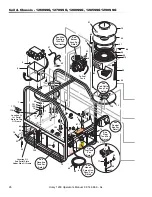

Operrations

Operation Instructions

Before Starting

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness, replace as required.

1.

Read all manuals provided with this pressure

washer. Become familiar with location and function

of all operating and safety controls.

2.

Connect the water supply hose to the float tank

water inlet (standard garden hose connector). The

water faucet and supply hose must be capable of

providing 6.0 GPM.

3.

Fill the burner fuel tank. Use kerosene, #1 grade

home heating oil, #1 or #2 diesel fuel.

DO NOT USE GASOLINE.

4.

Fill the gasoline tank. Use lead free gasoline

minimum 86 octane.

DO NOT

use gasoline

containing more than 10% ethanol, 15% MTBE, or

5% methanol.

5.

Check pump and engine oil levels.

6.

If detergents are to be used, only use detergent for

pressure washers. Follow instructions on detergent

container.

IMPORTANT: Before installing the pressure nozzle

on initial start-up, turn on the water supply and

allow water to run from the end of the wand until

clear to prevent the pressure nozzle from clogging.

IMPORTANT: If the pressure washer has not been

used for an extended period of time, remove the

pressure nozzle from the end of the wand and turn

on the water supply. Allow water to run from the

end of the wand until clear.

7.

Install the proper pressure nozzle for your cleaning

needs on end of wand.

IMPORTANT: The trigger gun provided with this

pressure washer is equipped with a manual trigger

lock to prevent accidental operation of the trigger

gun. The manual trigger lock should be used

whenever the trigger gun is not in use.

Fuel Pump

Some 1200 models are equipped with an electric fuel

pump which operates only when the engine is running.

The pump is primed when the key switch is held in the

start position. In the event that the engine stalls for any

reason the fuel pump will shut off.

WARNING: The fuel pump installed on this machine

has been adjusted at the factory to provide a

maximum pressure of 1.3-1.7 PSI at the pump

outlet. Whenever the fuel pump is replaced the new

pump must be adjusted using the following proce-

dure:

AVERTISSEMENT: La pompe à carburant installée

sur cette machine a été ajustée à l'usine pour

fournir une pression maximale de 1,3-1,7 PSI au

niveau de la sortie de la pompe. Chaque fois que la

pompe à carburant est remplacée, la nouvelle

pompe doit être réglée en utilisant la procédure

suivante.

1.

Place the ignition switch in the OFF position.

2.

Disconnect the fuel line from the engine mounted

fuel filter and connect a fuel pump pressure gauge

(0-5 PSI) to the fuel pump discharge line.

3.

Turn the ignition key to the start position and

observe pressure gauge. Pressure must be set to

between 1.3 and 1.7 PSI. It will be necessary to

bleed off accumulated pressure in line prior to each

gauge reading. Turn screw on top of fuel pump to

adjust pressure (CCW to decrease, CW to

increase).

4.

After adjustment, reconnect fuel line to engine

mounted fuel filter and start machine. Check for

fuel leakage and tighten fittings/clamps as

required.

To Start

DANGER: DO NOT point wand or spray gun at

yourself or at any person. Bodily injury may result

from water under high pressure.

DANGER : NE PAS pointer la lance ou le pistolet

pulvérisateur dans votre direction ou la direction

d'une autre personne. L'eau sous haute pression

peut causer des lésions corporelles.

Manual Trigger Lock

Pre

ss

ure

Nozzle

Hotsy 1200 Operator’s Manual 8.914-366.0 - AL