23

3) The "OUTPUT TEST" button provides a relay sequence test. Make sure the control

switch is in the "ICE" position, then press the "OUTPUT TEST" button. The correct

lighting sequence should be 1, 4, 3, 2. Some components (e.g., the compressor) will

cycle during the test. Note that the order of the relays from the outer edge of the board

is 1, 4, 3, 2. After checking the sequence, the unit automatically starts at the 1 minute

fill cycle. If the LEDs light in a different sequence, the control board is bad and should

be replaced.

5. Control Board Replacement

The application switch located between relay X3 & X4 must be set to match the original

board application. Place this switch in the "ALP" position. The dip switches should be

adjusted to the factory default settings. See "II.C.3.a) Default Dip Switch Settings." S4

dip switch #8 must remain off.

D. Harvest Control – Thermistor

A thermistor (semiconductor) is used for a harvest control sensor. The resistance varies

depending on the suction line temperatures. The thermistor detects the temperature of

the evaporator outlet to start the harvest timer. No adjustment is required. If necessary,

check for resistance between thermistor leads, and visually check the thermistor

mounting, located on the suction line next to the evaporator outlet.

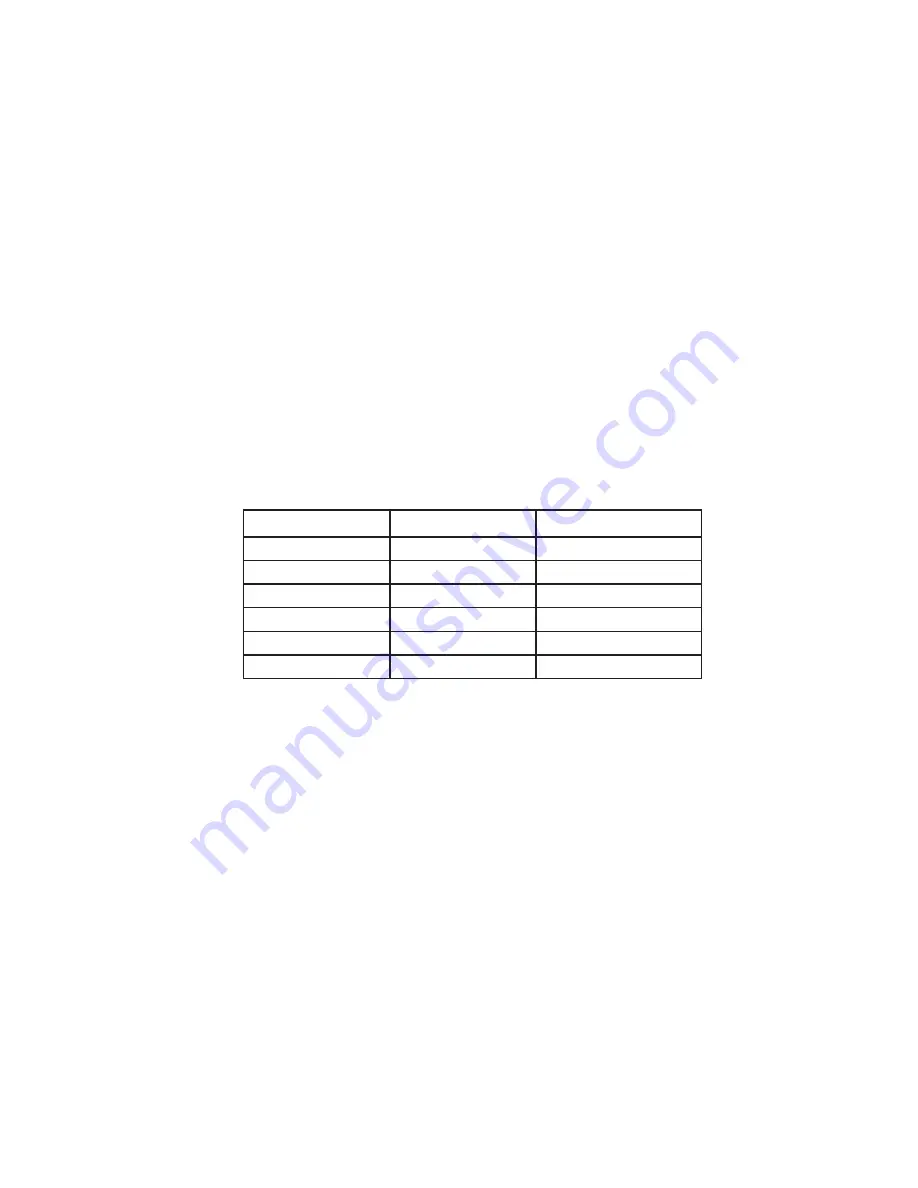

Temperature (°F)

Temperature (°C)

Resistance (kΩ)

0

-18

14.401

10

-12

10.613

32

0

6.000

50

10

3.871

70

21

2.474

90

32

1.633

Check a thermistor for resistance by using the following procedure:

1) Disconnect the connector K3 on the board.

2) Remove the thermistor. See "V.I. Removal and Replacement of Thermistor."

3) Immerse the thermistor sensor portion in a glass containing ice and water for

2 or 3 minutes.

4) Check for a resistance between thermistor leads. Normal reading is within 3.5 to 7 kΩ.

Replace the thermistor if it exceeds the normal reading.