42

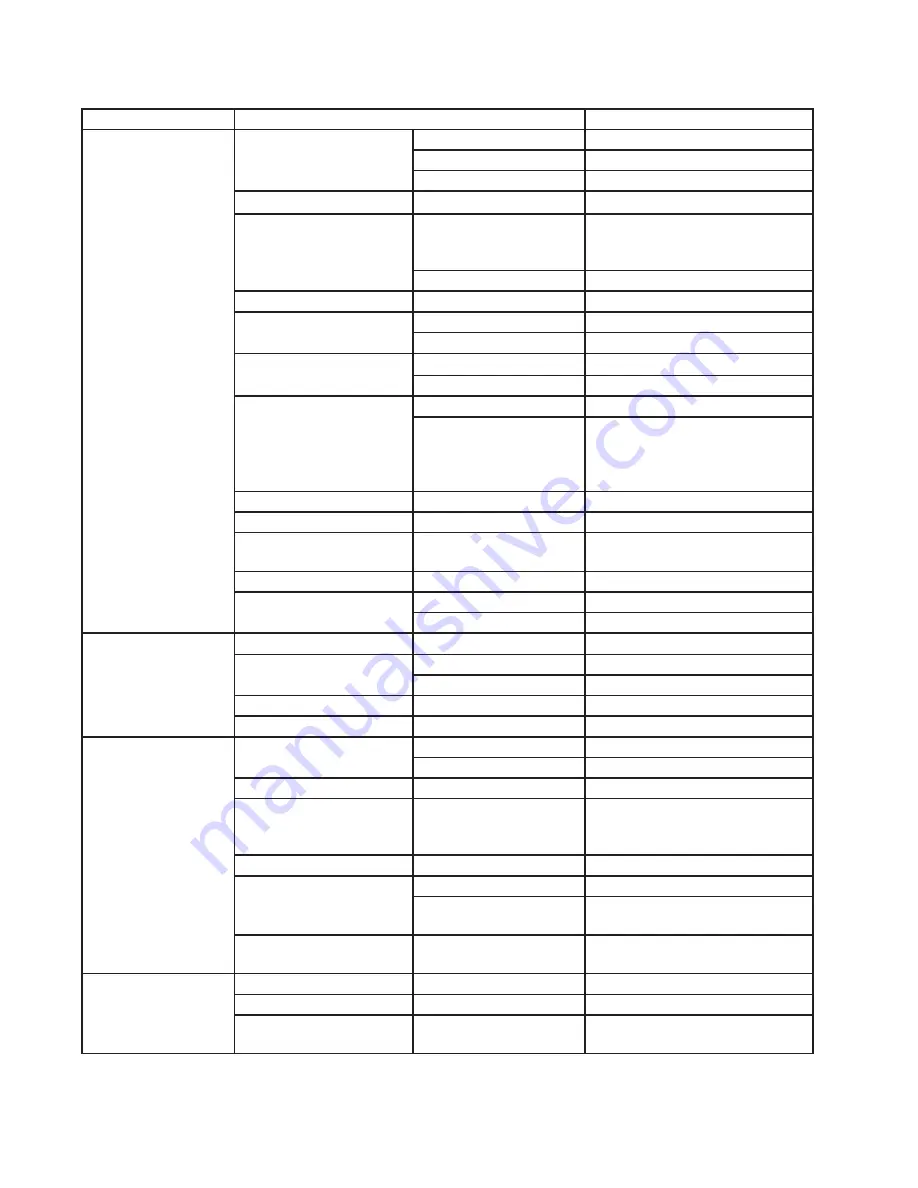

B. Diagnosis Chart

Problem

Possible Cause

Remedy

[1] Compressor will

not start—no

current draw.

a) Power Supply

1. "OFF" position.

1. Move to "ON" position.

2. Loose connection(s). 2. Tighten or reconnect.

3. Failure.

3. Call electrician.

b) Cord and Plug

1. Defective.

1. Replace.

c) Circuit Breaker

(kitchen)

1. Tripped.

1. Check and reset. Call

electrician if breaker trips

repeatedly.

2. Defective.

2. Call electrician.

d) Transformer

1. Open coil winding.

1. Check continuity and replace.

e) Wiring to Control Board 1. Loose connection(s). 1. Tighten.

2. Faulty.

2. Check continuity and replace.

f) Voltage

1. Too low.

1. Call electrician.

2. Too high.

2. Call electrician.

g) High Pressure Switch

1. Bad contacts.

1. Check continuity and replace.

2. Has operated 5 or

more times in one

hour. (E4 should be

displayed)

2. Determine why pressure

switch is activated.

h) Thermistor

1. Defective.

1. Check and replace.

i) Control Board

1. Defective.

1. Replace control board.

j) Compressor Overload 1. Defective. (Contacts

open)

1. Replace.

k) Compressor

1. Open windings.

1. Check continuity and replace.

l) Relay (Condensing

Unit)

1. Bad contacts.

1. Replace.

2. Open coil winding.

2. Check and replace.

[2] Compressor will

not run—draws

current and trips

on overload.

a) Voltage

1. Too low.

1. Call electrician.

b) Start Relay

1. Bad contacts.

1. Replace.

2. Open coil windings.

2. Replace.

c) Compressor

1. Locked rotor.

1. Replace.

d) Start Capacitor

1. Defective.

1. Check and replace.

[3] Compressor runs

intermittently and

trips on overload.

a) Voltage

1. Too low.

1. Call electrician.

2. Too high.

2. Call electrician.

b) Condenser Filter

1. Clogged.

1. Clean filter.

c) Refrigerant Line or

Component

1. Plugged or restricted. 1. Clean and replace drier. Clean

and replace capillary tube heat

exchanger assembly.

d) Condenser Fan Motor

1. Failed.

1. Replace.

e) Refrigerant

1. Overcharged.

1. Evacuate and recharge.

2. Non-condensibles in

system.

2. Evacuate and recharge.

f) Location of Unit

1. Restricted air flow to

condenser.

1. Move unit or increase

ventilation.

[4] Cabinet

temperature too

high; compressor

will not start.

a) Thermistor

1. Defective.

1. Check and replace.

b) Compressor Relay

1. Defective.

1. Check and replace.

c) Control Board

1. Defective.

1. Replace.

Summary of Contents for HUF40A

Page 6: ...6 Units mm in 1a HUR40A D HUF40A D 1 HUR40A HUF40A ...

Page 7: ...7 2 HWR40A HWF40A Units mm in 2a HWR40A D HWF40A D ...

Page 8: ...8 3 HUR68A HUF68A Units mm in 3a HUR68A D HUF68A D ...

Page 9: ...9 4 HWR68A HWF68A Units mm in 4a HWR68A D HWF68A D ...

Page 10: ...10 5 HUR96A 5a HUR96A D Units mm in ...