MAN0878-09-EN_XLE_XLT_UserManual

A u g u s t 2 3 , 2 0 1 8

P a g e 147 | 158

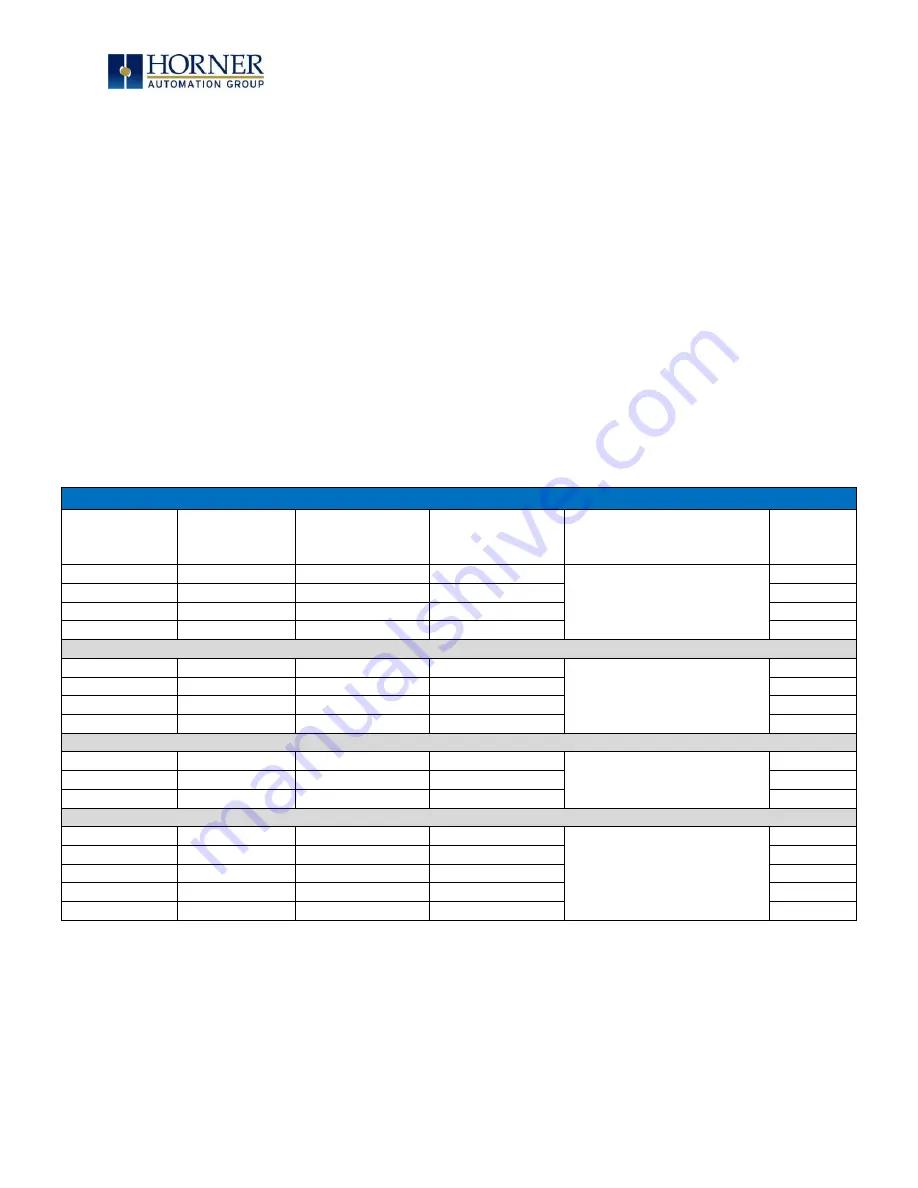

19.4 Modbus Addressing Table for XLE/XLT Units

To access XLE/XLT registers, a Modbus Master must be configured with the appropriate

register type and offset. This is usually accomplished with one of two methods:

Method 1: The first method uses Traditional Modbus References, in which the high digit

represents the register type and the lower digits represent the register offset (starting with

Register 1 for each type). Since only four register types can be represented in this manner,

XLE/XLT Modbus Function Blocks pack several XLE/XLT register types into each Modbus

register type. Starting addresses of each XLE/XLT register type are shown in the Traditional

Modbus Reference column of the Table 19.1.

Method 2: The second method requires the Modbus Master to be configured with a specific

Modbus Command and Modbus Offset. The supported Modbus commands and the associated

offsets are also illustrated in table below, Table 19.1.

XLE/XLEe Modbus Table

Table 19.1

–

XLE/XLEe Modbus Master Mapping

XLE/XLEe

Reference

Maximum

Range

Trad.

Modbus Ref.

(5 digits)

Expanded

Modbus Ref.

(6 digits)

Modbus Command(s)

Modbus

Offset

%I1

2048

10001

010001

Read Input Status (2)

0

%IG1

64

13001

013001

3000

%S1

13

14001

014001

4000

%K1

10

15001

015001

5000

%Q1

2048

00001

000001

Read Coil Status (1)

Force Coil (5)

Force Multiple Coils (15)

0

%M1

2048

03001

003001

3000

%T1

2048

06001

006001

6000

%QG1

64

09001

009001

9000

%AI1

512

30001

030001

Read Input Register (4)

0

%AIG1

32

33001

033001

3000

%SR1

192

34001

034001

4000

%AQ1

512

40001

040001

Read Holding Register (3)

Load Register (6)

Load Multiple Registers (16)

0

%R1

2488

40513

040513

0

%R1

2048

43001

043001

3000

%AQG1

32

46001

046001

6000

%R1

9999

--

410001

10000