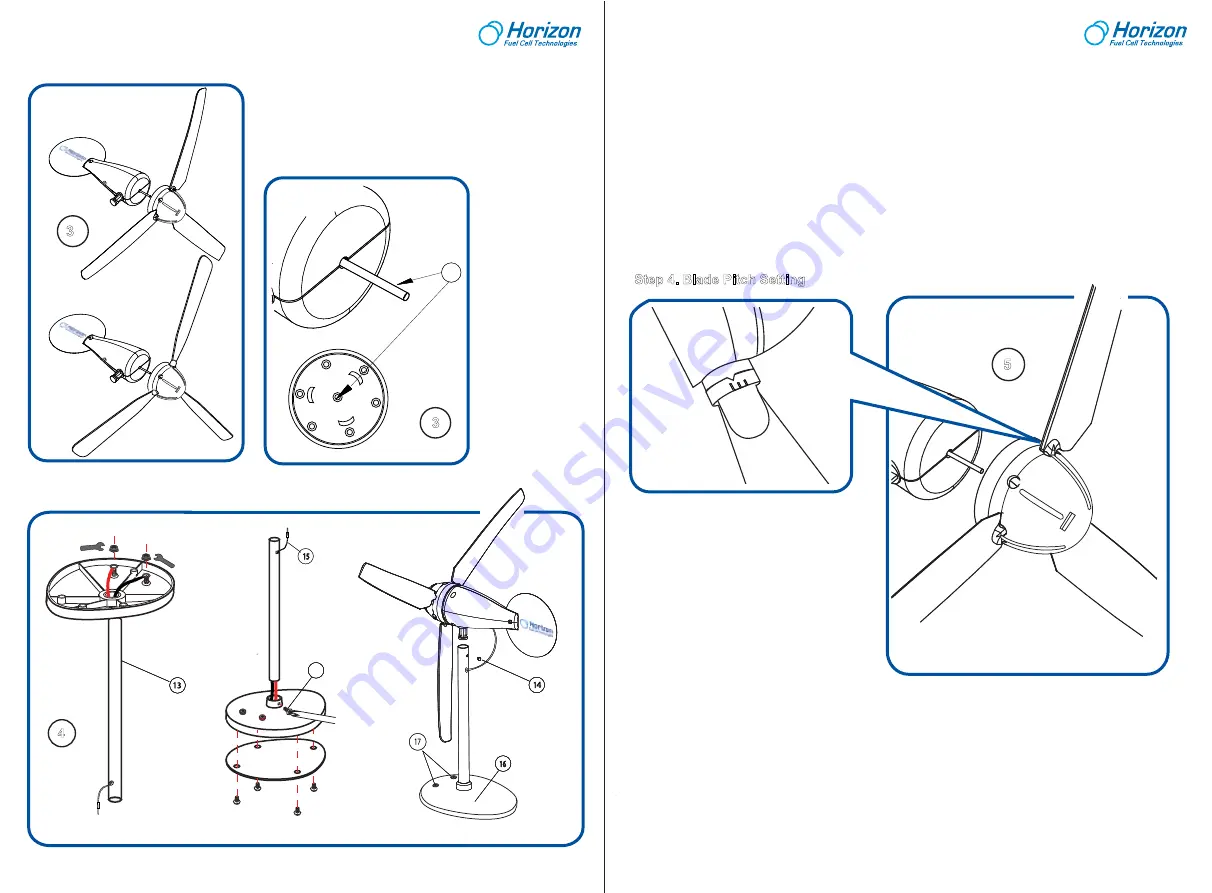

Step 2. Blade Unit Installation

Step 3. Post and Support Base Assembly

Push the rotor shaft to the rotor base to ensure the main body

and rotor head are properly connected. Make sure you press

the Blade Unit all the way onto the shaft. Check that the Blade

Unit is securely connected onto the shaft of the turbine. If not

properly installed, the rotor may not effectively turn the rotor

shaft and will not generate electricity.

Enable Yawing:

Disable Yawing (Not shown in the Assembly Drawing):

Yaw- To turn about on vertical axis.To move unsteadily or weave.

The wire connector hole should be located on the

same

side of the tube (13) with two vertically aligned holes. Insert

the Aluminium Tube into the Support Base. Install the Body Assembly onto the top of the Aluminium Tube and secure it with

the screw (14). The screw should be secured from the

back

side of the wind turbine body into the groove of the plastic

stud to

enable

yawing and movement of the turbine body.

The wire connector hole should be located on the

opposite

side of the tube (13) with two vertically aligned holes.

Insert the Aluminium Tube into the Support Base. Install the Body Assembly onto the top of the Aluminium Tube and

secure it with the screw (14). The screw should be secured from the

front

side of the wind turbine body through the

hole on aluminum tube into the solid plastic stud to

disable

yawing and movement of the turbine body.

5

V

*

3

3

To adjust and set the pitch of the blades,

carefully pull out the blade and rotate it to adjust

the pitch. Totally you have 3 pitches, which can

be adjusted.

The blades themselves have different set angles at different sections to enhance the performance. This setting is

to compensate the rotating speed of the blade at different radius (sections) so that the blades will not stall at a

particular section. You may have to learn more about a parameter called Tip Speed Ratio to understand more

thoroughly. This Ratio defines how fast the turbine is rotating under a wind speed environment. By changing the

blade pitch, this ratio will be changed. Thus the output power of the turbine is changed. Each adjustment

represents a change of 22 degrees. Therefore, the pitch is allowed to be adjusted from 6 to 50 degrees.

At smaller pitch value settings, the start up wind speed has to be very high. Maximum output power occurs at a

pitch of around 28 degrees. The start up wind speed is higher at a lower pitch setting. If the wind speed is low you

should increase the pitch so that you can achieve a higher power output.

Step 4. Blade Pitch Setting

The Pitch Angle

4

50

o

28

o

6

o

11

12

18