6 FUNCTIONALITIES

71

�

Changing the IP address

1.

Press the IP ADDRESS button.

The IP ADDRESS screen will be displayed.

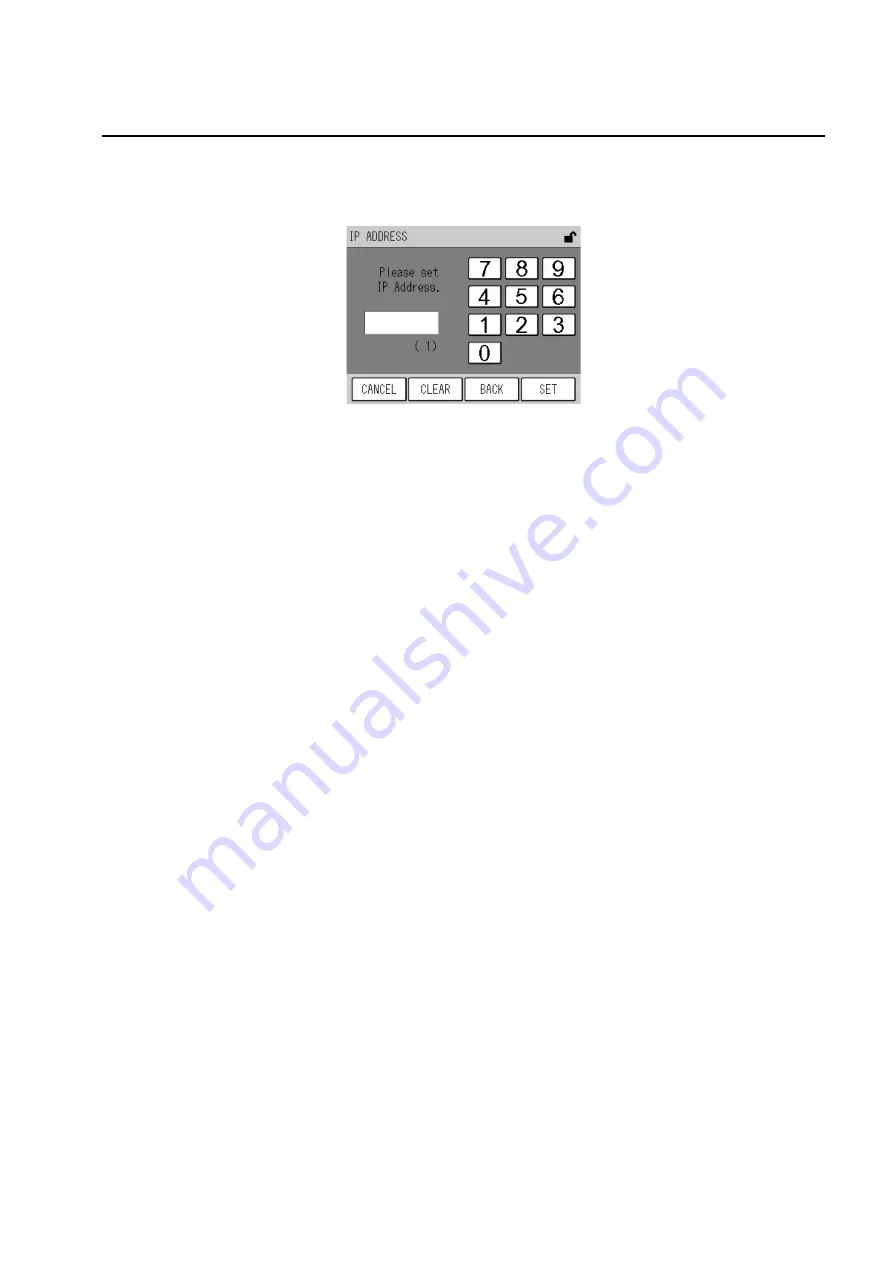

Fig. 91 IP ADDRESS screen

The currently set IP address is displayed in parentheses below the edit box.

Use the numeric keypad to enter a value in the following range:

The keys allow you to perform the following operations.

2.

Use the numeric keypad to enter a desired value.

3.

Press the [SET] key. You will return to the TCP/IP SETTING screen.

At this stage, the changed setting is not reflected. For the reflection of the setting, see "

�

Reflecting the TCP/IP setting" (page 74).

[Setting range]: 0 to 255

[CANCEL]:

Returns to the TCP/IP SETTING screen without changing the setting.

[CLEAR]:

Deletes the value entered in the edit box.

[BACK]:

Deletes the previously entered value (1-digit).

[SET]:

Establishes the changed value and then returns to the TCP/IP

SETTING screen.

Summary of Contents for APSA-370

Page 1: ...Ambient SO2 monitor APSA 370 Operation Manual CODE GZ0000051251C...

Page 10: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ...2 Miyanohigashi Kisshoin Minami ku Kyoto 601 8510 Japan http www horiba com...