6 FUNCTIONALITIES

47

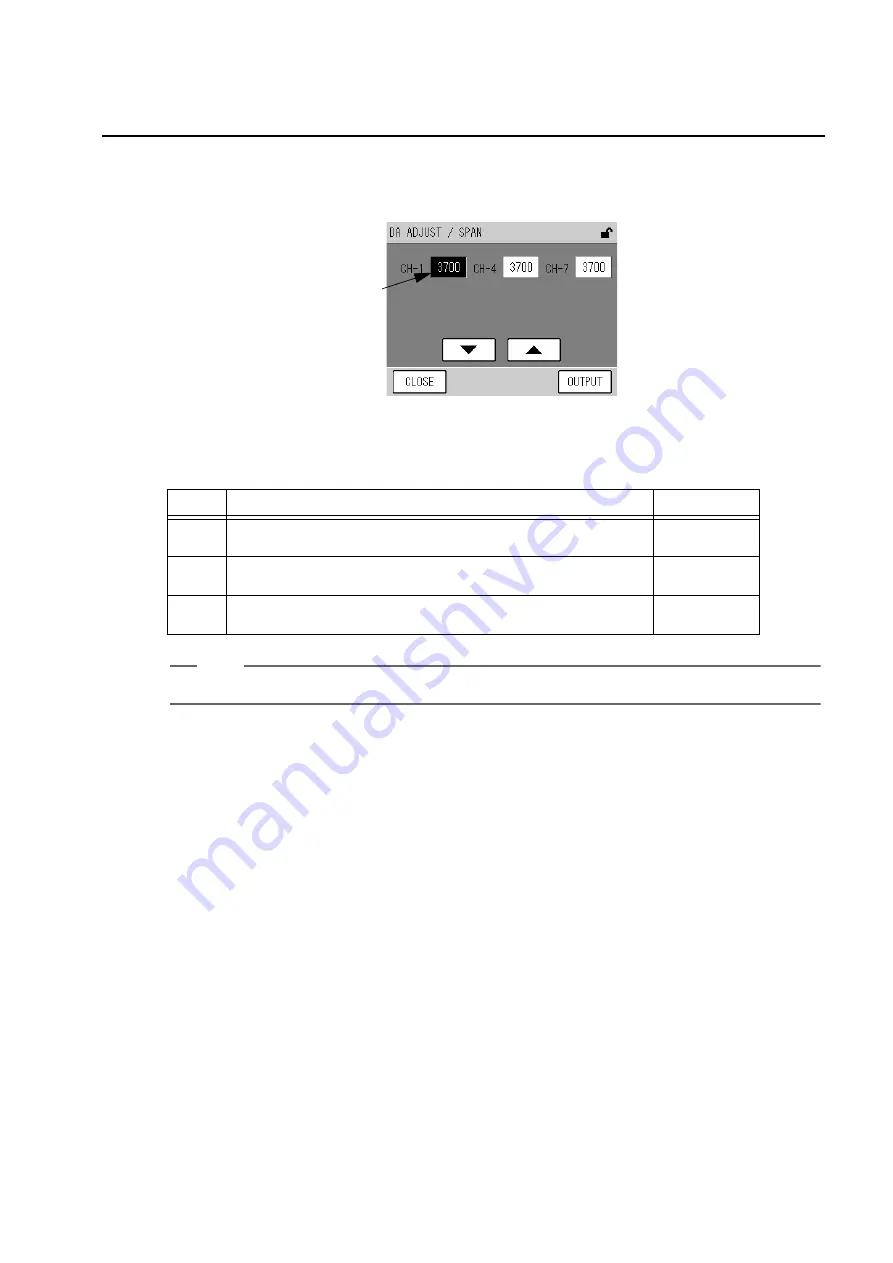

Span output adjustment

1.

Output [100%] on the ANALOG OUTPUT screen and then press the [SPAN] key.

The DA ADJUST/SPAN screen will be displayed.

Fig. 58 DA ADJUST/SPAN screen

The respective output point values of the channels are displayed.

The outputs allocated to the channels are as follows:

Tip

For the terminal block output, see the rear panel signal table at the end of this document.

Press a point value button, and the button will be highlighted.

In this state, the following buttons allow you to perform the following operations.

The keys allow you to perform the following operations.

2.

Press the point value button for the channel to be adjusted. The selected point

value will be highlighted.

3.

Change the point value by pressing the [

] or [

] button.

4.

To establish all the point values, press the [OUTPUT] key.

5.

Press the [CLOSE] key to return to the ANALOG OUTPUT screen (Fig. 56 on page

44).

6.

Check the output (page 45). If necessary, repeat the above steps to make

readjustment.

Point value

CH

Analog output

Terminal

CH-1

Non-insulated output of momentary value (0 V to 1 V)

(ANALOG OUTPUT 1)

C1 — C4

CH-4

Insulated output of momentary value (0 V to 1 V)

(ANALOG OUTPUT 2)

A8 — A9

CH-7

Non-insulated output of rolling average value (0 V to 1 V)

(ANALOG OUTPUT 2)

C5 — C8

[

]:

Increases the point value for the selected channel. A 10-point increment increases the

output about 3 mV.

[

]:

Decreases the point value for the selected channel. A 10-point decrement decreases

the output about 3 mV.

[CLOSE]:

Returns to the ANALOG OUTPUT screen.

[OUTPUT]:

Establishes each point value.

Summary of Contents for APMA-370

Page 1: ...Ambient CO monitor APMA 370 Operation Manual eng CODE GZ0000051249J...

Page 8: ......

Page 12: ......

Page 106: ......

Page 107: ...2 Miyanohigashi Kisshoin Minami ku Kyoto 601 8510 Japan http www horiba com...