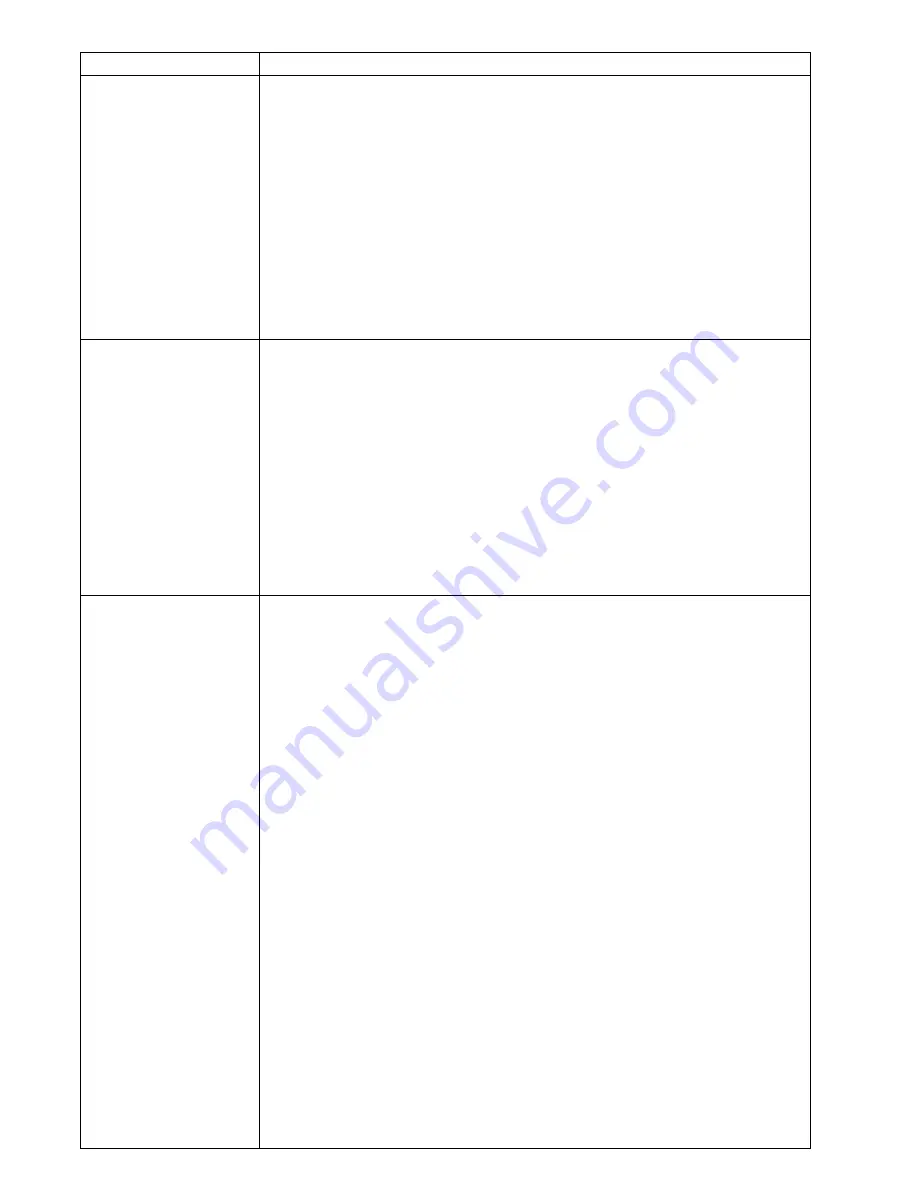

15

Fault Symptoms

Rectification

4. While this

welding

equipment

is operated,

fault indicator

is off, HF

electricity

releasing is

available, and

welding current

output is

unavailable.

1. Possible disconnection of welding torch cable.

2. Possible disconnection of earth cable, or unavailability of

connection of the earth cable and work piece.

3. The connection between positive output terminal or the

gas or electricity output terminal and this welding

equipment is possibly unavailable. Reconnect them if

necessary.

5. While is this

welding

equipment is

operated, the

fault indicator

is off, no

electricity

releasing, and

the arc starting

available.

1. The cable connection between the transformer of arc

starting and power PCB is possibly unavailable. Check

and reconnect it.

2. Possible oxidization of electricity releasing parts occurs.

Or the distance is larger than the maximum distance

available. Remove the oxidization of the electricity

releasing parts and adjust the distance of the electricity

releasing parts to range of 1mm.

3. Possible damage to MMA/TIG switch. Replace them if

necessary.

4. Components of HF arc starting circuit are possibly

damaged. Check and replace them if necessary.

6. While this

welding

equipment is

operated, fault

indicator is on,

and there is no

output.

1. It is possible of over-current protection status. Switch

off the power supply, wait till the fault indicator is off,

and restart this welding equipment.

2. It is possible of over-heating protection status. Wait till

the fault indicator is off, and the welding operation will

be available.

3. Possible fault with Inverter circuit. Disconnect the power

supply plug (VH-07) of transformer of MOS PCB. And

restart this welding equipment.

3.1 If the fault indicator is still on. Turn off the power

supply of this welding equipment. Disconnect the

power supply plug (VH-03) of HF arc starting.

3.1.1 If the fault indicator is on, MOFESTS of top PCB is

possibly defective. Replace it, if necessary.

3.1.2 Possible damage of transformer of center PCB.

Replace it if necessary.

3.2 If the fault indicator is off.

3.2.1 Possible damage of transformer of center PCB.

Replace it if necessary. Measure the inductance

value and Q value. L=0.9-1 .6mH Q>35. If both

of the inductance value and Q value are

comparatively low, replace them.

3.2.2 Possible damage of secondary rectifier of

transformer. Replace it if necessary.

4. Possible damage of feed back circuit. Replace it if

necessary.