Excessive oil on the after cooler pipe or compressor

head usually indicates air leakage. Locate air leaks with

soap solution while the compressor is operating.

While

the compressor is in the off cycle, check the unloaders

under pressure.

Excessive oil consumption is a difficult problem.

Before repair, take the following steps:

a.

Confirm the

Complaint-Oil at the tank drain does

not necessarily indicate

high oil

consumption.

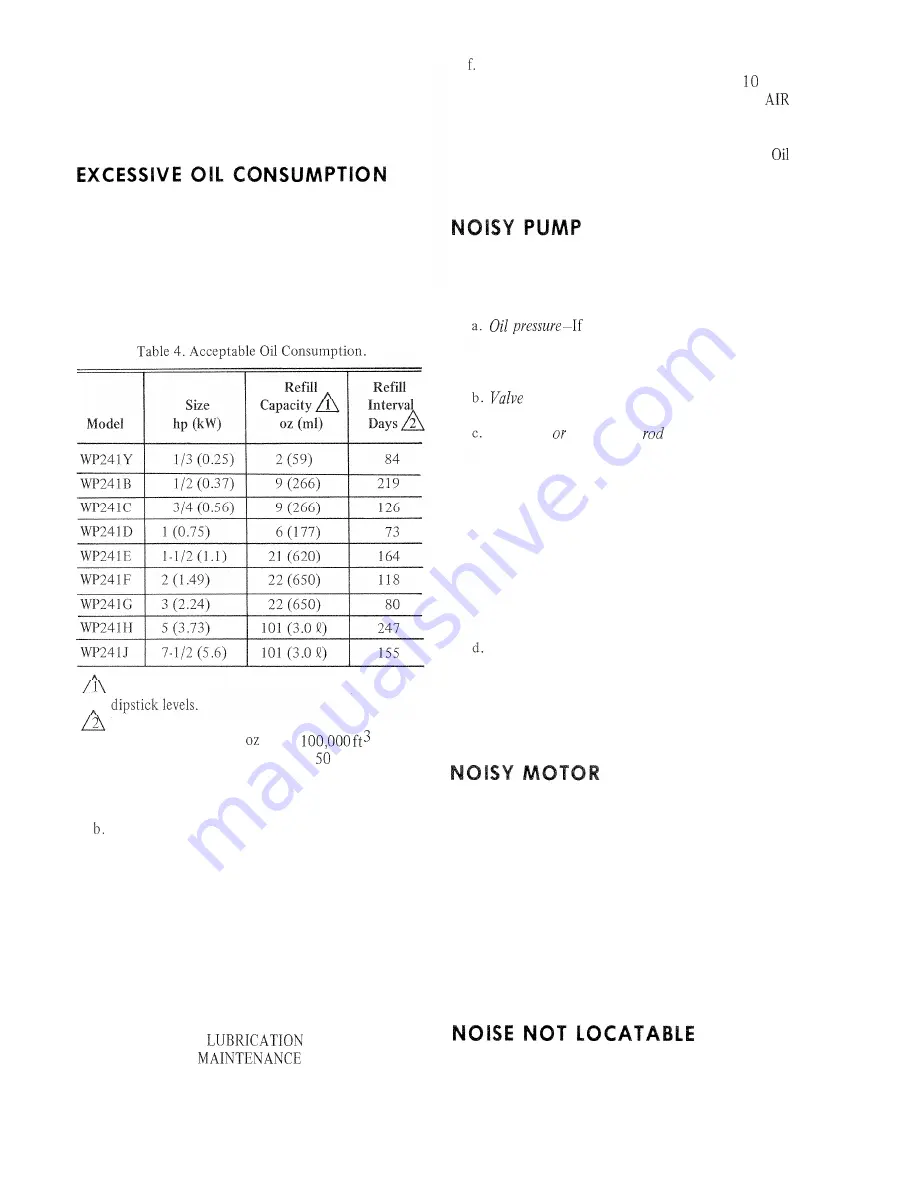

Table 4 shows acceptable oil consumption in terms

of fill amount and time between refills.

Oil capacity in crankcase between high and low

Days running time between high and low dipstick

levels, based on three oil per

air used

(31

ml

oil per Ml air used) and

percent maxi-

mum duty cycle. Does not allow for spillage or

leakage.

Make certain proper grade of nondetergent oil is

being used (see Table 2) and compressors are not

being overfilled. Overfilling always causes high oil

consumption. Oil level should never be above the

high mark on the dipstick.

c. Check for leaks.

d. Check intake filter/piping and crankcase breather

valve(s) for cleanliness and obstruction.

e. Check for excessive oil pressure or high percent

operation (see

and PRESSURE

paragraphs in

section). If, after

performing the above, a unit is still considered an

oil consumer with no apparent external cause, then:

Check pump-up and cycle pressures against the

values in Table 3. Differences greater than

per-

cent indicate worn parts (see WON’T PUMP

paragraph).

g. Remove valves and examine piston top for oil.

wetting is acceptable, but an accumulation of oil

indicates a defective pump.

The

most common reason for a noisy pump is a loose

flywheel or motor pulley. Check for these first, then

check:

low,

check pump as described in

WRONG

OIL

PRESSURE paragraph.

Lack

of oil

pressure may have caused bearing damage.

assemblies

-Make certain they are tight.

Wrist pin connecting

bearings-Stop

pump

and remove belts. Using the flywheel, rotate pump

back and forth about two inches (5 1 mm). If knock

is heard, a bad wrist pin or connecting rod bushing

probably exists. Inspect the rod bushings by

removing side plate and rod caps or

remove

head

and observe piston while rocking flywheel. Piston

should follow movement without play (except at

top and bottom dead center where piston appears

to hesitate). Inspect cylinder and head for carbon

build-up.

Bad main

bearings-Check for end play by attempt-

ing to move flywheel in different directions. Listen

and feel for any play. End play on the crankshaft

is usually eliminated by removing one of the

shims

beneath the bearing housing adjustment plate. A

slight drag, when turned by hand, is proper,

Check for a loose

motor

pulley. A low-pitch growl is

an indication

of low voltage.

If noise is slight, lubricate motor in accordance with

instructions on nameplate. Noise should disappear so

motor runs properly. Watch for dry bearings, as

these

shorten motor life. To check bearings, stop motor,

remove belt and check for side play in motor shaft. Turn

motor by hand. Any side play or noise is an indication

of bad bearings. If bearings are bad, replace motor. End

play (movement or motor shaft in and out) is common

in this type of motor and is not an indication of wear.

Use a large screwdriver or similar implement. Place

the point end against suspected areas and the other against

the ear. Listen for abnormalities.

75-7268

8