68-0150

10

VR8405

OPERATION

If main burner flame is restarted successfully, operation

continues as described above. Gas control operation is de-

scribed in more detail below.

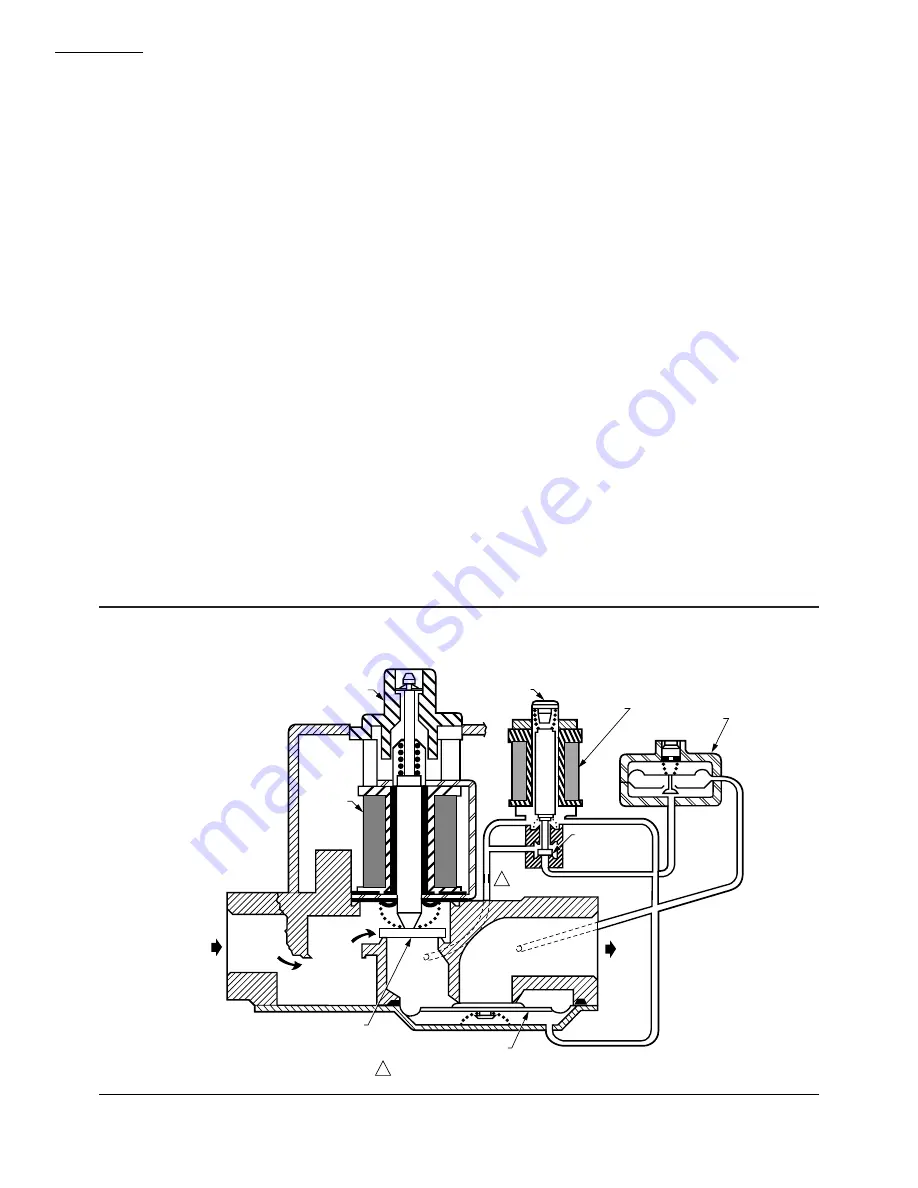

VALVE POSITION DURING THERMOSTAT OFF

CYCLE

Each valve is positioned as shown in Fig. 8 when the:

• Gas control knob is in the ON position.

• Thermostat is not calling for heat.

The first automatic valve is closed. The second automatic

valve operator is de-energized, closing the channel to the

pressure regulator, and opening a channel to the underside

of the second automatic valve operator valve diaphragm.

The combination of spring pressure under the second auto-

matic valve diaphragm and lack of outlet pressure hold the

diaphragm firmly closed. Main burner gas flow is blocked

by both valves.

WHEN THERMOSTAT CALLS FOR HEAT

When the thermostat calls for heat, the DI module gener-

ates a spark at the main burner and the first automatic valve

and second automatic valve operators are energized, Fig. 9.

The first automatic valve opens, and the second automatic

valve operator valve disc is lifted off its seat. This diverts

gas flow from the second automatic valve diaphragm, and

causes a reduction of pressure on the underside of this

diaphragm. The reduced pressure on the bottom of the auto-

matic valve diaphragm repositions the diaphragm down-

ward, away from the valve seat, allowing main burner gas

flow.

Standard-Opening Pressure Regulation (VR8405M)

During the ON cycle, the servo pressure regulator pro-

vides close control of outlet pressure, even if inlet pressure

and flow rate vary widely. Any outlet pressure change is

immediately reflected back to the pressure regulator dia-

phragm, which repositions to change the flow rate through

the regulator valve and, thus, through the automatic valve.

If outlet pressure begins to rise, the pressure regulator

diaphragm moves slightly higher, allowing less gas flow to

the gas control outlet. This increases gas pressure under the

automatic valve diaphragm and repositions the valve disc

closer to the seat. Thus, flow of gas through the second

automatic valve is reduced, and outlet pressure falls to the

desired level.

If outlet pressure begins to fall, the pressure regulator

diaphragm moves slightly lower, allowing more gas flow to

the gas control outlet. This decreases gas pressure under the

second automatic valve diaphragm and repositions the

valve disc further from the seat. Thus, gas flow through the

second automatic valve is increased, and outlet pressure

rises to the desired level.

Slow-Opening Pressure Regulation (VR8405H)

Slow-opening gas controls function the same as stan-

dard-opening models except that when the thermostat calls

for heat, the second automatic valve opens gradually. Open-

ing is slowed because a flow restrictor in the passage from

the second automatic operator slows the rate at which gas

pressure is reduced under the second automatic valve dia-

phragm after the second automatic operator opens. Outlet

FIRST

AUTOMATIC

VALVE

SOLENOID

CONTROL

KNOB

GAS

CONTROL

INLET

SECOND AUTOMATIC

VALVE OPERATOR

SECOND

AUTOMATIC

OPERATOR

SOLENOID

SECOND

AUTOMATIC

OPERATOR

VALVE DISC

SERVO PRESSURE

REGULATOR

GAS

CONTROL

OUTLET

SECOND AUTOMATIC

VALVE DIAPHRAGM

FIRST AUTOMATIC VALVE

NOTE: AUTOMATIC VALVE OPERATOR AND SERVO

PRESSURE REGULATOR SHOWN OUTSIDE GAS

CONTROL FOR EASE IN TRACING GAS FLOW.

SLOW-OPENING GAS CONTROL HAS A GAS FLOW RESTRICTOR IN THIS PASSAGE.

M9114

1

1

Fig. 8—Position of gas control components during thermostat Off cycle. Both valves positioned the

same; one valve shown for simplicity.