U2 COMBINATION VIEWING HEAD AND SIGNAL PROCESSORS

66-2071—02

4

NOTE: If the fault and flame contacts are wired to 220 VAC voltage and cable runs are long, it may be necessary to use

isolating/interposing relays to reduce induced noise.

Table 3. U2 Wires and their function.

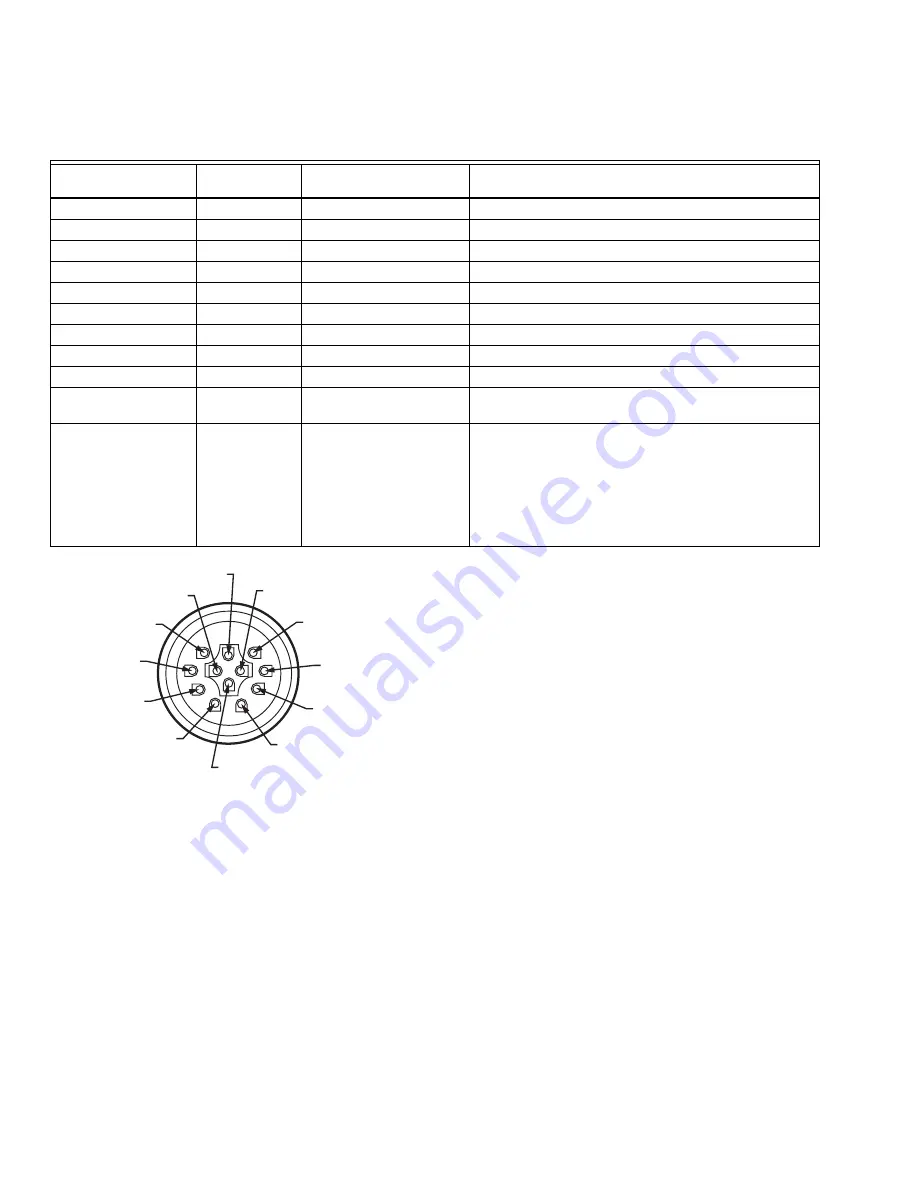

Fig. 1. Connector Pinout.

NOTES:

—

It is recommended to use shielded pairs of cable.

However, any cable can be used as long as ana-

log output and communication cables are individ-

ually shielded. Honeywell offers C12S cable with

12 conductors for use with the U2.

—

18 AWG is recommended

—

Wiring must be in conduit or tray as permitted by

code. Hazardous location wiring must meet area

classifications.

Mounting and Sighting

Mounting is 1 in. NPT (F). Refer to Fig. 7 for suggested U2

mounting. Before beginning the actual installation, determine

the best location for mounting the viewing head based upon

the following factors:

Pressure

The U2 lens will withstand 500 psi. If the U2 will be exposed to

pressures over 500 psi, contact your distributor or Honeywell

for guidance.

Temperature

The U2 can withstand an ambient temperature of 158 ºF

(70 ºC). The case temperature of the housing must not

exceed 158 ºF (70 ºC). Purge air will help reduce conducted

heat through the sight pipe and flange. A heat insulating Ultem

locking coupler adapter (R-518-PT12, R-518-PT12L) is

required and will reduce the conducted heat, however, direct

radiation can cause the housing case temperature to exceed

limits. If the ambient heat (direct radiation) is excessive, then a

fiber optic extension should be considered. The extension

uses a fiber optic cable assembly between the sight pipe and

the U2, allowing the U2 to be placed further away from the

heat source. Refer to the Fiber Optic Manual 69-2683 or

contact your distributor or Honeywell for assistance with fiber

optic selection and pricing.

The U2 models also have an internal sensor for measuring

temperature. To access the temperature reading at the U2,

refer to Fig. 2.

Purge Air

The U2 does not have a purge air connection directly on it, so

purge air must be provided via the mounting method. Refer to

the ACCESSORIES section and Fig. 7 for suggested U2

mounting. Purge air is used to prevent very hot gases from

reaching the U2 by continuously blowing cooler air through the

sight pipe. Air required is about 0.13 Nm

3

/min (5 SCFM)

delivered at 25 mm (1 in.) above the maximum back pressure

as measured at the “Y” or “T” section of the purge air

Pipe Fitting

Connection (CAB19)

Connector

(CAB22)

Function

Comments

Drain wire

Shield

Cable shielding

Tie to ground (black)

Black

Yellow/Green

Ground

Power ground

Red

Black #10

Power

Connect to 22-26 VDC

Green

Yellow #3

Relay common

Common for both flame and self check relays

Yellow

Yellow #4

Self check relay

Normally open contact

Grey

Yellow #2

Flame relay

Normally open contact

Brown

Yellow

- RS 485 communication

Modbus Connection

White

White

+ RS 485 communication

Modbus Connection

Blue

Black #7

Future use

Future use

Orange

Black #8

Current output

0-20 or 4-20 mA output corresponding to flame count. Use

ground as return line.

Purple

Black #9

File select

Grounded = parameter file 0

+24V = parameter file 1

NOTE: The file input wire should not be left uncon-

nected or in an unknown state. If not being

used or if using the default file 0, connect the

file input wire to ground.

M33313

NOT USED

YELLOW

YELLOW 2

YELLOW 3

YELLOW 4

YELLOW/GREEN

SHIELD

WHITE

BLACK 10

BLACK 9

BLACK 8

BLACK 7