MSXX10, MSXX20 SERIES

63-2607—26

8

Mounting

CAUTION

Device Malfunction Hazard.

Improper shaft coupling tightening causes device

malfunction.

Tighten shaft coupling with proper torque to

prevent damper shaft slippage.

CAUTION

Actuator Damage Hazard.

Using actuator as shaft bearing causes device

damage.

Use actuator only to supply rotational torque. Avoid

any side loads to actuator output coupling bearings.

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a

wrench.

Forcibly turning the motor shaft can damage the

gear train.

To mount the actuator to an external drive shaft of a

damper, proceed as follows:

1.

Place actuator over damper shaft; and hold mounting

bracket in place. See Fig. 9.

2.

Mark screw holes on damper housing.

3.

Remove actuator and mounting bracket.

4.

Drill or center-punch holes for mounting screws (or

use no.10 self-tapping sheet metal screws).

5.

Turn damper blades to desired normal (closed) posi-

tion.

6.

Place actuator and mounting bracket back into posi-

tion and secure bracket to damper box with sheet

metal screws.

7.

Using 10 mm wrench, tighten shaft coupling securely

onto damper shaft using minimum 120 lb-in. (13.6

Nm), maximum 180 lb-in. (20.3 Nm) torque.

NOTE:

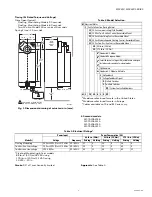

See Fig. 8 for proper mounting to a square

damper shaft.

Fig. 8. Proper mounting to square damper shaft.

Fig. 9. Mounting actuator to damper housing.

WIRING

CAUTION

Electrical Shock or Equipment Damage Hazard.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than

one disconnect.

IMPORTANT

All wiring must comply with local electrical codes,

ordinances and regulations.

DAMPER SHAFT

M21007

M20956

ENSURE THAT MOUNTING ASSEMBLY PREVENTS ACTUATOR

ROTATION AND ALLOWS ACTUATOR TO FLOAT ALONG

INDICATED AXIS. WHEN TOO TIGHT, THE RESULTING BINDING

CAN DAMAGE THE ACTUATOR OR REDUCE TORQUE OUTPUT.

THE BRACKET CAN BE BENT TO ALLOW MOUNTING THE

ACTUATOR PARALLEL TO THE MOUNTING SURFACE.

1

PART NO. 5006427-001

1

2

2