ML7999C UNIVERSAL PARALLEL-POSITIONING ACTUATOR

32-00079EF—01

6

Actuator Initial Setup

IF the system is being commissioned, perform the

following to set the ML7999C and linkage/damper of the

air/fuel/fgr.

1.

During the actuator setup, use the auto seek closed

or the CW/CCW buttons to find the mechanical fixed

stop of the actuator. The air/fuel/fgr is not connected

at this time.

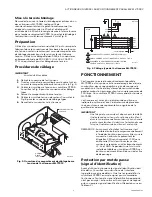

Fig. 7. Mechanical end stop changes for auto seek open/closed function.

2.

Auto seek closed to find the actuator mechanical

closed fixed stop. See Fig. 8.

Fig. 8. Auto seek closed to find actuator mechanical

closed fixed stop.

3.

Move the actuator closed position five (5) degrees off

the mechanical closed fixed stop. See Fig. 9.

Fig. 9. Move actuator closed position five degrees off

mechanical closed fixed stop.

4.

Verify that the gas/fuel/fgr linkage/dampers are at

their closed positions.

5.

Tighten the set screws on the actuator.

OPEN ACTUATORS 2 - 5

DEGREES. LOCK

ACTUATOR CLOSED

POSITION.

ACTUATOR

MECHANICAL CLOSED

FIXED STOP.

Mechanical open/closed fixed stops of actuator (ML7999C).

Move actuator 5 degrees of mechanical closed fixed stop. Verify that air/fuel/fgr have been adjusted to their

mechanical fixed closed position. Mechanically lock air/fuel/fgr shaft to ML7999 actuator.

Open actuator 2 - 5 degrees. Lock actuator closed position.

Move actuator 5 degrees off mechanical open fixed stop. Lock actuator open position.

ACTUATOR

MECHANICAL OPEN

FIXED STOP.

MOVE ACTUATOR 5

DEGREES OFF MECHANICAL

OPEN FIXED STOP. LOCK

ACTUATOR OPEN POSITION.

MOVE ACTUATOR 5 DEGREES

OFF MECHANICAL FIXED STOP.

MECHANICALLY LOCK

DAMPER/LINKAGE TO ACTUATOR.

M36779