63-2483—2

2

ML6185

SPECIFICATIONS • ORDERING INFORMATION

Specifications

MODELS: ML6185 Spring Return Direct Coupled Rotary

Actuators.

ML6185A: Medium Torque (50 lb-in.) Direct Coupled

Rotary Actuator without auxiliary switches and

without time-out function.

ML6185C: Medium Torque (50 lb-in.) Direct Coupled

Rotary Actuator with two line voltage rated aux-

iliary switches, without time-out function.

ML6185D: Medium Torque (50 lb-in.) Direct Coupled

Rotary Actuator without auxiliary switches and

with time-out function.

ML6185F: Medium Torque (50 lb-in.) Direct Coupled

Rotary Actuator with two line voltage auxiliary

switches and time-out function.

ELECTRICAL RATINGS:

Power Input: 24 Vac

±

20%, 50/60 Hz.

Power Consumption:

ML6185A-C: 12 VA maximum at 24 Vac.

ML6185D,F: 12 VA maximum at 24 Vac.

Auxiliary Switch Ratings: 120, 240 Vac: 3 AFL, 18 ALR,

1A pilot duty.

Control: Standard models include nonplenum UL/

CSA rated, 30V, 60

°

C, 20 gauge cable.

Auxiliary Switch: UL/CSA rated 300V 90

°

C, 18

gauge.

TORQUE RATINGS (at Rated Voltages):

Lift and Hold: 50 lb-in. (6 N•m).

Breakaway Minimum: 50 lb-in. (6 N•m).

Stall Minimum: 50 lb-in. (6 N•m) spring return.

Stall Driving Maximum: 130 lb-in. (15 N•m).

ACTUATOR STROKE: 95

°

Nominal

±

2

°

, mechanically

limited.

ACTUATOR TIMING at 90

°

Stroke:

88 +/- 2 seconds synchronous at 60 Hz from 0

°

F to

140

°

F;

106 +/- 2 seconds at 50 Hz;

100 seconds at -30

°

F.

Spring Wind Timing (Upon Power Restoration Only):

100 seconds nominal at 60 Hz, 120 seconds at 50 Hz.

Spring Return Timing:

10 seconds minimum per 90

°

at 72

°

F no load;

30 seconds maximum per 90

°

at 72

°

F at rated load;

5 minutes maximum at -30

°

F at rated load.

AMBIENT TEMPERATURE RANGE: -30

°

F to +140

°

F

(-35

°

C to +60

°

C).

STORAGE TEMPERATURE: -30

°

F to 150

°

F (-35

°

C to

65

°

C).

HUMIDITY: 5 to 95 percent relative humidity, noncondensing.

MOUNTING: Mounts directly on horizontal 3/8 in. to

5/8 in. (12 to 16 mm) round or square damper shaft.

Minimum shaft length required: 3.5 in. (76 mm) when the

shaft attachment is made on the side of the actuator

opposite the duct; 0.65 in. (16 mm) when the hub is

mounted on the shaft before the actuator is installed. Most

actuators are shipped with specifically sized hubs. Some

models contain an assembly with assorted hub inserts.

Mounting bracket is included with most models.

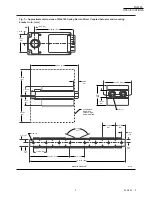

DIMENSIONS: See Fig. 1.

Ordering Information

When purchasing replacement and modernization products from your TRADELINE

®

wholesaler or distributor, refer to the TRADELINE

®

Catalog or price sheets for complete ordering number, or specify:

1. Model number.

2. Application.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North,

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Limitée, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9. International Sales and Service

offices in all principal cities of the world.