GB-9

D

GB

F

NL

I

E

?

1

2

Power

yellow and permanently lit?

!

Safety interlock input signal is interrupted, no

voltage at terminal 5. The tightness test is still

being carried out. No enable signal is issued to

the automatic burner control unit.

•

Check safety interlocks.

!

Fuse F2 defective.

•

Replace fuse F2, see page 9 (Replacing the

fuse).

?

1

2

Power

yellow and flashing?

!

Permanent remote reset. The remote reset signal

has been active for more than 10 s.

•

The warning signal is cancelled once the remote

reset signal to terminal 11 has been removed.

?

1

2

Power

red and permanently lit?

!

Incorrect jumper/DIP switch setting.

•

Correct jumper and DIP switch setting, see

pages 7 (Setting measurement time tM)

and 6 (Setting the test instant). Then press

the reset button.

!

Internal error.

•

Remove the unit and return it to the manufacturer

for inspection.

?

1

2

Power

red and flashing?

!

Too frequent burner start commands. The TC

performs a fault lock-out. The start commands

are limited to 5 x in 15 minutes.

▷

As long as this limit is not exceeded, another

start-up attempt is possible after three further

minutes. If a tightness test is completed, the

counter which limits the number of start com-

mands is reset.

•

Then press the reset button.

!

Too many remote resets. More than 5 resets

have been conducted within the last 15 minutes,

either automatically or manually.

!

Consecutive fault caused by a previous fault

whose actual cause has not been remedied.

•

Pay attention to previous fault messages.

•

Remedy cause. Then press the reset button.

?

1

2

Power

or

1

2

Power

red and permanently lit?

!

The valve is leaking. The TC performs a fault

lock-out.

•

Replace the valve.

!

Wiring of the TC to the valves is faulty.

•

Start the program and observe the interspace

pressure p

z

. The pressure must change during

the TEST phase. Check the wiring.

!

Inlet pressure p

u

< 10 mbar.

•

Provide the min. inlet pressure of 10 mbar.

!

Interspace pressure p

z

cannot be reduced.

•

The volume downstream of the valve on the

burner side must be 5 times higher than the

volume between the valves and atmospheric

pressure must prevail.

!

The measurement time t

M

is too long.

•

Readjust t

M

, see page 7 (Setting measure-

?

1

2

and

1

2

Power

red and permanently lit?

!

During the tightness test, the TC has determined

that inlet valve 1 and outlet valve 2 have been

reversed (fault lock-out).

•

Check the wiring. Then press the reset button.

? No LED lit even though mains voltage ap-

plied?

!

Fuse F1 defective.

•

Replace fuse F1, see page 9 (Replacing the

fuse).

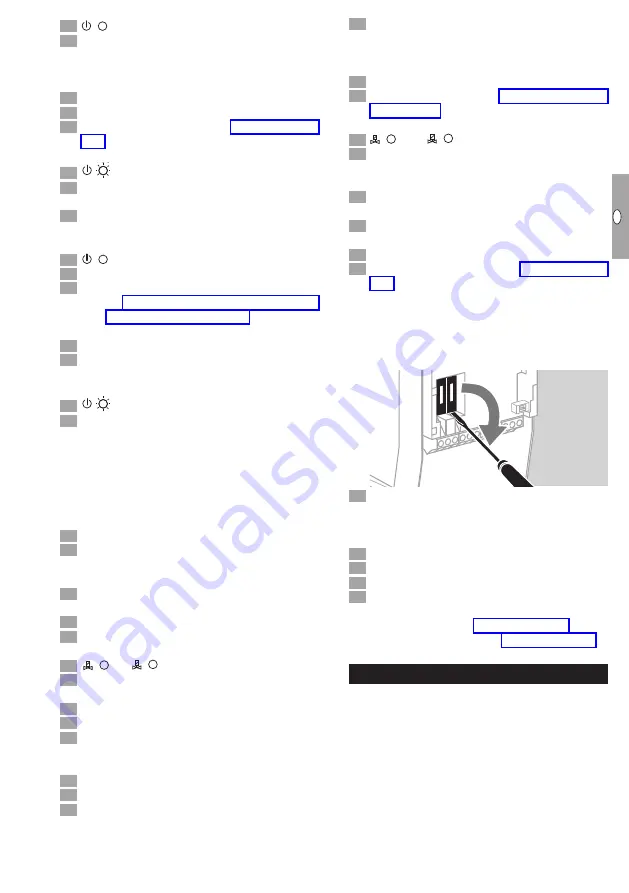

Replacing the fuse

▷

The fuses F1 and F2 can be removed for in-

spection.

▷

Insert a screwdriver into the opening in the con-

tact guard to prise out the fuse.

Disconnect the TC from the electrical power

supply.

▷

Before opening the unit, the fitter should ground

himself.

Unscrew the housing cover.

Remove fuse F1 or F2.

4

Check function of fuse.

5

Replace the defective fuse.

▷

When replacing the fuse, use only the approved

fuse type, see page 10 (Technical data).

▷

Restart the TC, see page 8 (Commissioning).

Maintenance

Tightness controls TC require little servicing. We rec-

ommend carrying out a function check once a year

or twice a year in the case of biogas.