F118 IN-CEILING MEDIA AIR CLEANER

68-0209-2 Revised 11-07

8

OPERATION

Local, Federal and professional ventilation engineering

standards and codes prescribe minimum ventilation rates to

dilute air contamination in specific applications. The

ventilation rates usually assume the injection of outdoor air

measured as air exchange rate.

Using the F118 Air Cleaner to comply with ventilation

requirements is an acceptable alternative to ventilation with

outdoor air. However, at least 20 percent of a specified

ventilation code rate must be derived from outdoor air. The

F118 Air Cleaner filtered and re-circulated air can supply the

remaining 80 percent.

Airborne contaminants are always present in the air where

contaminant generation occurs. Air cleaning systems and

ventilators do not eliminate airborne contaminants; they

reduce excessive contaminant accumulation. To eliminate the

contamination, the source of contamination must be removed.

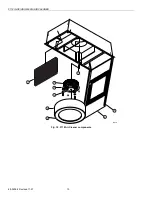

The F118 in Ceiling Media Air Cleaner was engineered to

improve indoor air quality for commercial and industrial

applications. The filters are effective for capturing atmospheric

dust, mold spores, smoke, fumes, mists and aerosols. See

Fig. 9.

Fig. 9. F118 Air Cleaner operation.

The air cleaner may be operated on high, medium, or low

speed, depending on the number of people and activities in

the space.

The unit may be used only while people are using the room, or

when contaminants from other sources must be removed from

the room. And the air cleaner may be operated continuously

to prevent buildup of airborne contaminants, even when the

room is unoccupied.

The CPZ™ sorbent module collects and holds gas-phase

compounds and vapors typically found in commercial and light

industrial facilities. These gases and vapors frequently appear

as odors that can be annoying and irritating. CPZ™ material

extends the maintenance service life.

The minimum recommended air exchange rate is 2.5 times

per hour. In a heavily contaminated area, up to 15 air

exchanges per hour can be necessary. The factors that

determine the rate of air exchange are:

•

Generation rates of the various pollutants;

•

Concentration level of the pollutants;

•

Desired contamination reduction level.

SERVICE

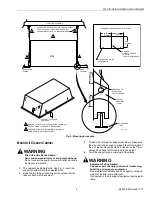

WARNING

Fire or Electric Shock Hazard.

Can cause personal injury or equipment damage.

Turn off power source before servicing air cleaner.

IMPORTANT

A very dirty filter reduces air cleaner airflow.

Opening/Closing Grille

IMPORTANT

Use this procedure when opening the grille to pre-

vent damage to the cover and prevent ceiling buck-

ling.

To open the grille and remove and replace the filters:

1.

Pull apart the spring-loaded plungers to disengage from

the grille.

2.

Turn the plungers to keep them from closing and reen-

gaging the grille.

3.

Slide the grille forward toward you. It can travel about

one inch.

4.

Slowly and carefully allow the grille to swing down.

To close the grille:

1.

Swing grille into the closed position.

2.

Engage the plungers.

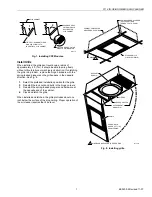

Particle Filter

The particle filter collects particles that are not trapped by the

pre-filter. The particle filter life is from 6 to 24 months (typically

12 to 24 months). Change modules and filters more frequently

in facilities that operate 24 hours a day. When the filter is

loaded with contaminants, there is a pulsing sound, and

decreasing air quality. Replace the filter when the pulsing

sound becomes audible.

IMPORTANT

The filter must be removed and replaced. Washing,

vacuuming or reverse air blasting does not clean it.

CAUTION

Equipment Damage Hazard.

Handling can damage the filter media.

Handle only the filter frame.

Do not touch the pleated filter media.

1.

Push aside the two spring-loaded support rods that hold

the filter frame in place.

2.

Rotate the rods; the filter is released and can be

removed.

3.

With both hands, slide the filter toward you.

4.

Place the removed filter in a plastic trash bag and dis-

pose of properly.

5.

Unwrap and install a new filter.

DROP

CEILING

LINE

PREFILTER

(WRAPS AROUND

PARTICLE FILTER)

1 (25)

11-1/2

(292)

INTAKE AIR

PARTICLE

FILTER

MOTOR

BLOWER

CPZ™ SORBENT

FILTER MODULE

CLEAN AIR

DISCHARGE

M14420