1-10

XL2 0 0

GENERAL INFORMATION

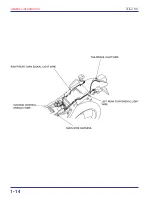

CABLE & HARNESS ROUTING

Note the following when routing cables and wire harnesses:

• A loose wire, harness or cable can be a safety hazard. After

clamping, check each wire to be sure it is secure.

• Do not squeeze a wire against a weld, or the end of its clamp.

• Secure wires and wire harnesses to the frame with their

respective bands at the designated locations. Tighten the

bands so that only the insulated surfaces contact the wires or

harnesses.

• Route harnesses so they are not pulled taut or have excessive

slack.

• Protect wires and harnesses with electrical tape or tubing

where they contact a sharp edge or corner. Clean all surfaces

thoroughly before applying tape.

• Do not use wires or harnesses with damaged insulation.

Rapair the wires by wrapping them with protective tape.

• Route wire harnesses to avoid sharp edges or corners.

• Avoid the projected ends of bolts and screws.

• Keep wire harnesses away from the exhaust pipes and other

hot parts.

• Be sure grommets are seated in their grooves properly.

• After clamping, check each harnesses to be certain that it is not

interfering with any moving or sliding parts.

• After routing, check that the wire harnesses are not twisted or

kinked.

• Wire harnesses routed along the handlebars shoud not be

pulled taut, have excessive slack, or interfere with adjacent or

surrounding parts in any steering position

• Do not bend or twist control cables. Damaged control cables

will not operate smoothly and may stick or bind.

O – Correct

X – Incorrect

Summary of Contents for XL200 2001

Page 1: ...SH O PMANU AL XL200 MOTO HONDA DA AMAZÔNIA LTDA 2001 1 ...

Page 15: ...XL2 0 0 GENERAL INFORMATION 1 11 ...

Page 16: ...XL2 0 0 1 12 GENERAL INFORMATION ...

Page 17: ...XL2 0 0 GENERAL INFORMATION 1 13 ...

Page 18: ...XL2 0 0 1 14 GENERAL INFORMATION ...

Page 19: ...XL2 0 0 GENERAL INFORMATION 1 15 NOTES ...

Page 22: ...XL2 0 0 LUBRICATION 2 0 CRANKSHAFT OIL FILTER ROTOR OIL PUMP COUNTERSHAFT MAIN SHAFT CAMSHAFT ...

Page 29: ...XL2 0 0 2 8 LUBRICATION NOTES ...

Page 48: ...XL2 0 0 FUEL SYSTEM 4 0 ...

Page 64: ...XL2 0 0 FUEL SYSTEM 4 17 NOTES ...

Page 67: ...5 0 XL2 0 0 ENGINE REMOVAL INSTALLATION ...

Page 92: ...XL2 0 0 CYLINDER HEAD VALVES 6 19 NOTAS ...

Page 95: ...XL2 0 0 CYLINDER PISTON 7 0 ...

Page 101: ...XL2 0 0 CYLINDER PISTON 7 7 NOTAS ...

Page 116: ...XL2 0 0 CLUTCH GEARSHIFT LINKAGE 8 13 NOTES ...

Page 119: ...XL2 0 0 ALTERNATOR STARTER CLUTCH 9 0 75 Nm 7 5 kg m 53 ft lb 5 Nm 0 5 kg m 4 ft lb ...

Page 129: ...XL2 0 0 ALTERNATOR STARTER CLUTCH 9 11 NOTAS ...

Page 132: ...XL2 0 0 CRANKSHAFT TRANSMISSION 10 0 12 N m 1 2 kg m 9ft lb ...

Page 144: ...XL2 0 0 CRANKSHAFT TRANSMISSION 10 13 NOTAS ...

Page 169: ...XL2 0 0 FRONT WHEEL SUSPENSION STEERING 11 23 NOTAS ...

Page 172: ...XL2 0 0 REAR WHEEL SUSPENSION 12 0 ...

Page 190: ...XL2 0 0 REAR WHEEL SUSPENSION 12 19 NOTAS ...

Page 226: ...XL2 0 0 IGNITION SYSTEM 16 7 NOTES ...

Page 237: ...XL2 0 0 ELECTRIC STARTER 17 9 NOTES ...

Page 240: ...XL2 0 0 LIGHTS METERS SWITCHES 18 0 ...

Page 248: ...XL2 0 0 LIGHTS METERS SWITCHES 18 9 NOTES ...

Page 250: ...XL2 0 0 19 WIRING DIAGRAM 19 1 19 ...

Page 257: ...MOTO HONDA DA AMAZÔNIA LTDA ...