9

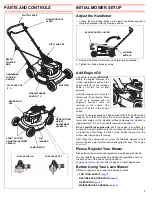

Blade Inspection

1. Turn the fuel valve OFF (

2. Disconnect the spark plug cap from the spark plug (

).

3. Tilt the mower to the right side so that the fuel cap side is up. This

will help to prevent fuel leakage and hard starting due to carburetor

flooding.

4. Inspect the blade for damage, cracks, and excessive rust or

corrosion.

A dull blade can be sharpened, but a blade that is excessively worn,

bent, cracked, heavily rusted, or otherwise damaged must be

replaced.

If a blade is bent, take the lawn mower to an authorized Honda

servicing dealer for inspection.

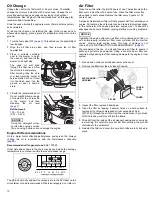

Blade Mounting Bolt Inspection

Inspect the blade bolts for any signs of damage

or looseness. If they are damaged, they must

be replaced.

If they appear loose, a torque wrench must be

used to accurately tighten the blade bolts to the

required torque. If you do not have a torque

wrench, take your lawn mower to an authorized

dealer to have the bolts replaced or tightened.

Use only Honda Genuine blade bolts and

special washers, since they are specifically

designed for this purpose. Replacement part

numbers are on

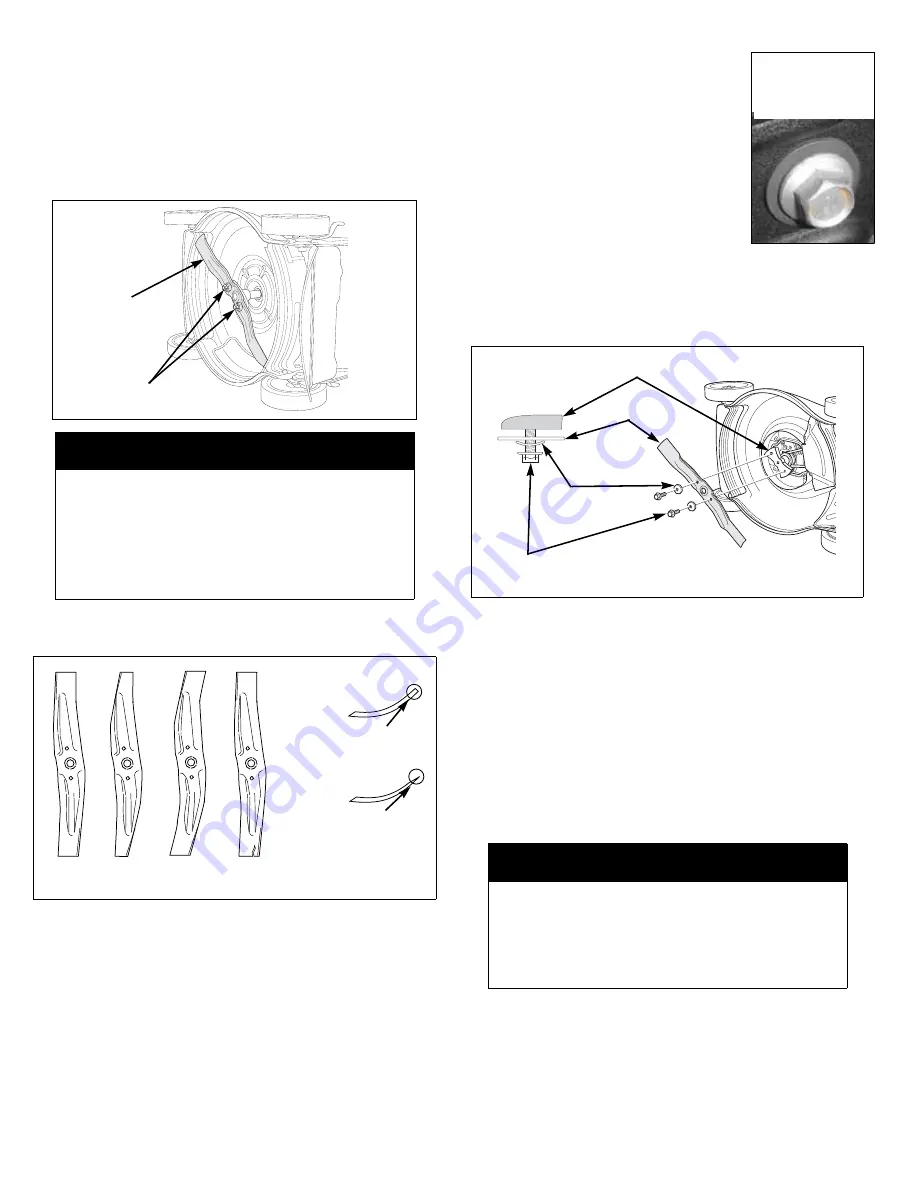

Blade Replacement

1. Remove the two blade bolts with a 14 mm (6 point) socket wrench.

Use a wooden block to prevent the blade from turning when

removing the bolts. Remove the blade.

2. Clean dirt and grass from around the blade mounting area.

3. Install the sharpened or replacement blade using the two blade

bolts and special washers as shown below.

The blade bolts and washers are specially designed for this

application. When replacing bolts and washers, use only Honda

Genuine replacement parts.

4. Tighten the blade bolts with a torque wrench to the specified

torque. Use a wooden block to prevent the blade from turning

when tightening the bolts.

Blade bolt torque:

36 ~ 43 ft-lb (49 ~ 59 N·m)

If you do not have a torque wrench, have an authorized Honda

servicing dealer tighten the blade bolts.

WARNING

A worn, cracked, or damaged blade can break, and

pieces of the damaged blade can become dangerous

projectiles.

Thrown objects can cause serious injury.

Inspect the blade regularly, and do not operate the mower

with a worn or damaged blade.

BLADE

BLADE BOLTS

NORMAL

WORN

BENT

CRACKED

NORMAL

TRAILING EDGE

EXCESSIVELY WORN

TRAILING EDGE

DANGER

If the blade bolts are not torqued properly, the blade could

loosen and be thrown from the mower.

Blades thrown from the mower could seriously hurt or kill

someone.

Ensure the blade bolts are torqued properly.

INSPECT WASHERS

AND BOLT HEADS

FOR LOOSENESS

AND DAMAGE

BLADE HOLDER

BLADE

SPECIAL

WASHER (2)

BLADE BOLT (2)