32

Chapter 1 Engine, clutch and gearbox

5 Piston ring wear is measured by removing the rings from

the piston and inserting them in the cylinder bore using the

crown of the piston to locate them approximately 25 mm (1 in)

from the top of the bore. Make sure they rest square with the

bore. Measure the end gap with a feeler gauge; if it exceeds

mm

in) the rings require renewal.

22 Examination and

cylinder barrel

1 The usual indications of a badly worn cylinder barrel and

piston are excessive oil consumption and piston slap, a metallic

rattle that occurs when there is little or no load on the engine. If

the top of the bore of the cylinder barrel is examined carefully, it

will be found that there is a ridge on the thrust side, the depth of

which will vary according to the amount of wear that has taken

place. This marks the limit of travel of the uppermost piston

ring.

2 Measure the bore diameter just below the ridge, using an

internal micrometer. Compare this reading with the diameter at

the bottom of the cylinder bore, which has not been subject to

wear. If the difference in readings exceeds 0 0 9 mm

in) it is necessary to have the cylinder rebored and to fit an

size piston and rings.

3 If an internal micrometer is not available, the amount of

cylinder bore wear can be measured by inserting the piston

without rings so that it is approximately 20 mm

in) from the

top of the bore. If it is possible to insert a 0 1 0 mm ( 0 0 0 4 in)

feeler gauge between the piston and the cylinder wall on the

thrust side of the piston, remedial action must be taken.

4 Check the surface of the cylinder bore for score marks or

any other damage that may have resulted from an earlier engine

seizure or displacement of the gudgeon pin. A rebore will be

necessary to remove any deep indentations, irrespective of the

amount of bore wear, otherwise a compression leak will occur.

5 Check the external cooling fins are not clogged with oil or

road dirt; otherwise the engine will overheat.

23 Cylinder head: valve removal, examination and renova-

tion

1 Remove each valve in turn, using a valve spring com-

pressor, and place the valves, springs, seats and collet halves in

a suitable box or bag marked to denote inlet or exhaust as

appropriate. Assemble the valve spring compressor in position

on the cylinder head, and gradually tighten the threaded portion

to place pressure on the upper spring seat. Do not exert undue

force to compress the springs, the tool should be placed under

slight load, and then tapped on the end to jar the collet halves

free. Continue to compress the springs until the collet halves

can be dislodged using a small screwdriver. Note that the valve

springs exert considerable force, and care should be taken to

avoid the compressed assembly flying apart. To this end, a small

magnet is invaluable for retrieving the collet halves, being more

delicate than fingers.

2 After cleaning the valves to remove all traces of carbon,

examine the heads for signs of pitting and burning. Examine

also the valve seats in the cylinder head. The exhaust valve and

its seat will probably require the most attention because these

are the hotter running of the two. If the pitting is slight, the

marks can be removed by grinding the seats and valves

together, using fine valve grinding compound.

3 Valve grinding is a simple task, carried out as follows:

Smear a trace of fine valve grinding compound (carborundum

paste) on the seat face and apply a suction grinding tool to the

head of the valve. With a semi-rotary motion, grind in the valve

head to its seat. It is advisable to lift the valve occasionally, to

distribute the grinding compound evenly. Repeat this operation

until an unbroken ring of light grey matt finish is obtained on

both valve and seat. This denotes the grinding operation is com-

plete. Before passing to the next operation, make quite sure that

all traces of the grinding compound have been removed from

both the valve and its seat and that none has entered the valve

guide. If this precaution is not observed, rapid wear will take

place, due to the abrasive nature of the carborundum base.

4 When deeper pit marks are encountered, it will be

necessary to use a valve refacing machine and also a valve seat

cutter, set to an angle of 45°. Never resort to excessive grinding

because this will only pocket the valve and lead to reduced

engine efficiency. If there is any doubt about the condition of a

valve, fit a new replacement.

5 Examine the condition of the valve collets and the groove

on the valve in which they seat. If there is any sign of damage,

new replacements should be fitted. If the collets work loose

whilst the engine is running, a valve will drop in and cause

extensive damage.

6 Measure the valve stems for wear, making reference to the

tolerance values given in the Specifications Section of this

Chapter.

7 Check the free length of the valve springs against the list of

tolerances in the Specifications. If the springs are reduced in

length or if there is any doubt about their condition, they should

be renewed.

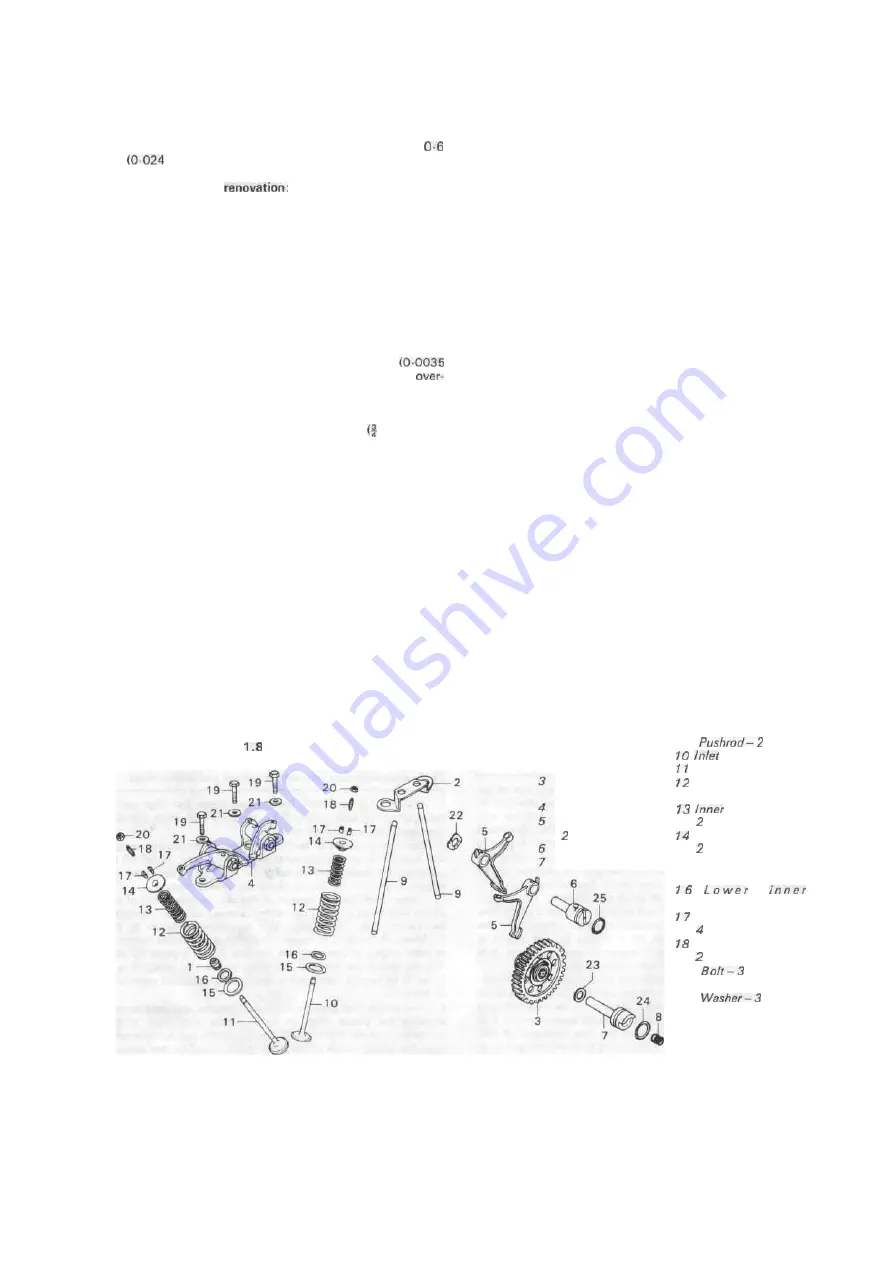

Fig.

Valve gear - component parts

Exhaust valve

stem seal

Pushrod guide

plate

Cam and gear

assembly

Rocker assembly

Cam follower —

off

Pivot shaft

Cam gear shaft

8 Spring

9

off

valve

Exhaust valve

Outer valve spring -

2 off

valve spring -

off

Upper spring seat —

off

1 5 L owe r outer

spring seat -2 off

spring seat — 2 off

Collet halves -

off

Adjusting screw -

off

19

off

20 Locknut-2 off

21

off

22 Wave washer

23 Washer

24 0 ring

25 0 ring