12

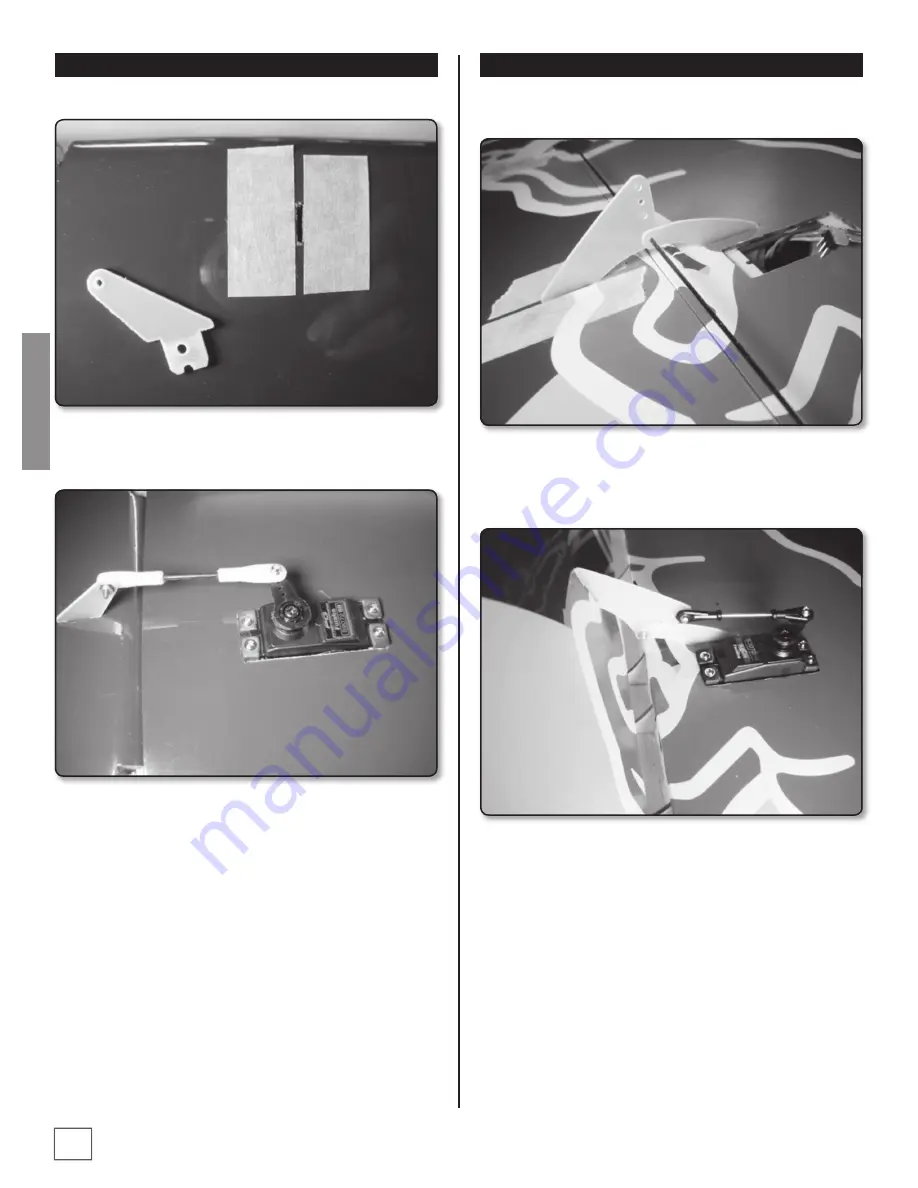

WING ASSEMBLY

❏

1. Glue the aileron levers into the aileron fl aps. Round the

fl anges and sand it. Cover the slots with tape.

❏

2. Glue the hinges into the main wings, looking for right

movement direction. In a second step glue the aileron fl aps to

the main wing. Take care for smooth movement of the fl aps.

❏

3. Mount the aileron servos so, that the servo lever is

nearer to aileron fl ap. Assemble the linkages and screw it to

the servo- and aileron levers with M2x10mm screws. (Thread

lock!). In neutral position of the aileron fl aps, the servo levers

and the linkages should enclose an angel of 90 degrees.

INSTALLATION OF THE LANDING FLAPS

All levers with 3 holes on the bottom are for the main wing. All

lever with 2 holes on the bottom are for landing fl aps.

❏

1. All levers should be glued to wings and fl aps carefully.

To have corresponding centers of rotation you can put a 2mm

carbon fi ber tube through the center of the hinges, until the

epoxy glue is hardened.

❏

2. Now you can screw the landing fl ap to the mainwing.

Use shims on both sides of the fi ber glass levers. The hinges

should have no gap but good movement. Fix all screwings

with thread

lock.

❏

3. Assemble the linkages with the ball links and screw

them to the levers. Take care for maximum way downwards

of the fl aps.

In the following picture you can see the servolever in neutral

position of the landing fl ap.

ENGLISH