GENERAL / Tightening

W1-2-6

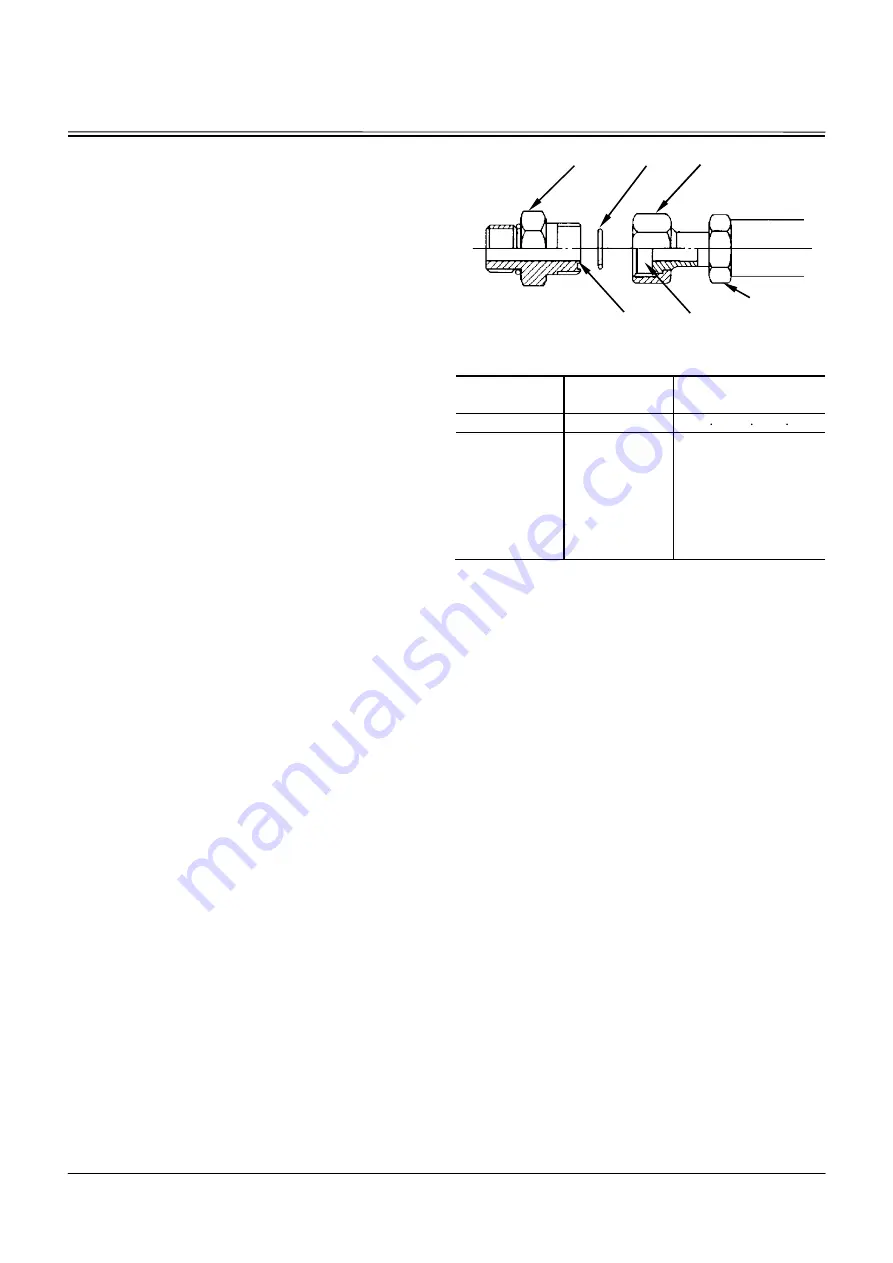

O-ring Seal Joint

O-ring (6) seats against the end face of adapter (7) to

seal pressure oil.

IMPORTANT: 1. Be sue to replace O-ring (6) with

a new one when reconnecting.

2. Before tightening nut (9), confirm

that O-ring (6) is seated correctly

in O-ring groove (e). Tightening

nut (9) with O-ring (6) displaced

will damage O-ring (6), resulting

in oil leakage.

3. Take care not to damage O-ring

groove (8) or sealing surface

(10).

Damage to O-ring (6) will cause

oil leakage.

4. If nut (9) is loose and oil is leak-

ing, do not re-tighten nut (9). Re-

place O-ring (6) with a new one

and check that O-ring (6) is cor-

rectly seated in place, tighten nut

(9).

M104-07-033

Wrench Size

mm

Wrench Size

mm

Tightening Torque

Union Nut

Hose Fittings

N m (kgf m, lbf ft)

19

17

29.5 (3.0, 21.5)

22

19

69 (7.0, 51)

27

22

93 (9.5, 69)

32

27

137 (14.0, 101)

36

30, 32

175 (18.0, 129)

41

36

205 (21.0, 151)

46

41

205 (21.0, 151)

7

6

9

8

1

Hose Fittings