--- 32 ---

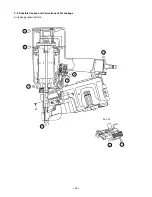

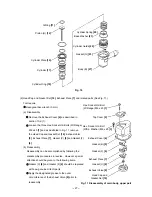

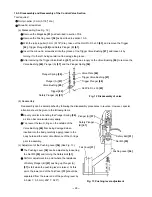

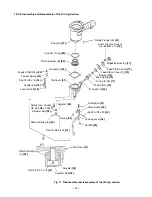

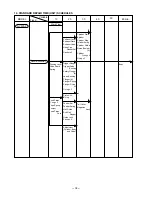

10-5. Disassembly and Reassembly of the Driving Section

Fig. 17 Disassembly and reassembly of the driving section

Piston Bumper (B) [29]

Body (B) [27]

Cylinder O-ring [28]

Feeder Spring [33]

Gasket (A) [30]

Tail Cover [31]

Feeder Shaft Ring [32]

Roll Pin D3 x 16 [34]

Magazine Bushing [77]

Safety Plunger (B) [61]

Seal Lock Hex. Socket

Hd. Bolt M5 x 10 [76]

O-ring (P-22) [71]

Feed Piston Cover [75]

Feed Piston Cover (A) [74]

Feed Spring [72]

Bumper [73]

Ratchet Spring (A) [40]

Nylock Hex. Socket

Hd. Bolt M8 x 22 [37]

Adjuster Bolt [38]

Roll Pin D2.5 x 18 [41]

Roll Pin D2.5 x 18 [41]

Spring [50]

Ratchet Spring

(A) [40]

Feeder Set [35]

Feeder Shaft [36]

Feed Piston [70]

O-ring (P-9) [69]

Pushing Lever [54]

Safety Bolt [51]

Roll Pin D3 x 45 [53]

Valve Guard [52]

Nut M5 [55]

Adjuster [39]

Adjuster [39]

Adjuster Bolt [38]

Tail Cover [31]

Summary of Contents for NV 83A2

Page 15: ... 12 Pushing Lever 54 Part NV 83A2 NV 83A Bent Welded Cover 105 ...

Page 46: ......