−

2

−

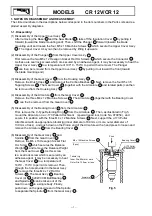

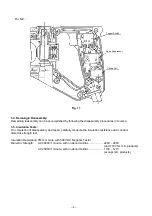

1-2. Reassembly:

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

(1) Insert 30 g of grease (Molub-Alloy #1) into both the Gear Cover and Upper Cover. Also apply a

liberal amount of grease to the following parts:

The 6202VVCM Ball Bearing

24

in the Gear Cover

26

, the Neelde Roller

17

, Connecting Piece

(A)

16

, the teeth portion of the Gear Ass’y

21

, the inside of the Connector

14

, the Connector

sliding portion in the Upper Cover Ass’y

11

, and the metal sliding portion of the Plunger

5

.

(2) When pressure fitting the Gear Ass’y

21

onto the Spindle

25

, do not forget to assemble Bearing

Cover (A)

23

.

(3) Prior to reinstalling the Plunger

5

into the Upper Cover Ass’y

11

, ensure without fail that the Felt

Packing

7

, Packing Washer

6

and 1AP12 O-Ring

8

are properly assembled.

(4) The screws listed below are seal lock screws. Once they have been removed, they must be treated

with Cemedine 1500 or ThreeBond TB2410 adhesive as indicated if they are to be used again.

z

#

M6 x 16 Hexagon Socket Flat Hd. Screws

18

z

#

M5 x 12 Hexagon Socket Flat Hd. Screws

15

z

#

M5 x 16 Machine Screws

10

z

#

M4 x 12 Machine Screws

44

..................................................................... ThreeBond TB2410

z

#

M4 x 12 Flat Hd. Screws

22

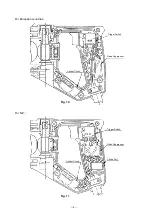

(5) When reassembling the Upper Cover Ass’y

11

onto the Gear Cover

26

, do not forget to assemble

the Seal Packing

12

.

(6) When reassembling the Handle Cover

56

onto the Housing Ass’y

42

, ensure without fail that none

of the leadwires are pinched between them.

(7) Tightening Torques:

D4 Tapping Screw ........................................................................... 20 ± 5kgf-cm (17.4 ± 4.34 in-lb)

D5 Tapping Screw ........................................................................... 30 ± 5kgf-cm (26 ± 4.34 in-lb)

M4 Machine Screw, Flat Hd. Screw ................................................ 15 - 20kgf-cm (13.02 ± 17.4 in-lb)

M5 Machine Screw .......................................................................... 30 - 55kgf-cm (26 ± 47.75 in-lb)

M5 Hexagon Socket Flat Hd. Screw ................................................ 50 - 60kgf-cm (43.41 ± 52.09 in-lb)

M6 Hexagon Socket Flat Hd. Screw ................................................ 80 ± 10kgf-cm (69.45 ± 8.68 in-lb)

11111111111111111111111111111111111111111111

Cemedine 1500

Summary of Contents for CR12

Page 1: ......