-22-

•

Crank case

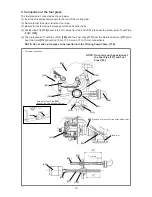

14. Disassembly and reassembly of the crank case

[Tool required]

• Hex. bar wrench (4 mm)

(1) Disassembly

• Remove the four Bolts M5

[13]

by using a hex. bar wrench (4 mm). You can now remove Crank Case

(A)

[6]

, Crank Case (B)

[44]

, and the Crank Shaft

[1]

.

• To disassemble Ball Bearing 6202C3

[4]

and the Oil Seal

[5]

, push both from the Oil Seal

[5]

side.

(2) Reassembly

Reassembly can be conducted by reversing the disassembly procedure. However, special attention

should be given to the following items.

• Do not reuse the Oil Seal

[5]

and Ball Bearing 6202C3

[4]

when disassembled from Crank Case (A)

[6]

and Crank Case (B)

[44]

.

• Do not reuse the Crank Case Packing

[3]

.

• Do not reuse the four Bolts M5

[13]

.

• Apply 50 to 100 mg of Piloknock Universal No. 0 (JX Nippon Oil & Energy) between the lips of the Oil

Seal

[5]

.

• Carefully clean the Crank Shaft

[1]

by using gasoline before mounting.

• Before mounting Crank Case (A)

[6]

and Crank Case (B)

[44]

, fully degrease their threaded holes.

Mount them without pinching Fuel Pipe (FKM)

[150]

.

• Assemble the Crank Case Packing

[3]

by correctly aligning its hole position without any deviation.

After matching Crank Case (A)

[6]

and Crank Case (B)

[44]

, check their outer peripheries and make

sure the Crank Case Packing

[3]

is along the Crank Case mating face.

• Cut off the protrusion of the Crank Case Packing

[3]

at the mating face of the Cylinder

[146]

after

mounting.

NOTE: Do not break the Crank Case Packing [3] when cutting it.

[1]

[3]

[4]

[5]

[6]

[44]

[5]

[4]

[13]

[46]

[45]