-13-

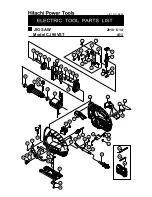

(1) Apply Nippeco SEP-3A grease to the following:

●

Entire Gear

[21]

, particularly its teeth

●

Both sides of Washer (A)

[25]

●

Both sides of Orbital Cam

[24]

●

Both sides of Balance Weight

[23]

●

Periphery of Connecting Piece (A)

[19]

●

Tooth plane of Armature

[31]

●

Contacting parts of Spindle

[26]

and Steel Ball D3.97

[62]

●

Entire Plunger

[15]

●

Sliding part of Roller Holder

[46]

and Needle Roller

[47]

(2) Apply Molub-Alloy No.777-1 grease to the following:

●

Inner diameter part of the gear assembly (metal part, grease stopper groove, and needle bearing part: 1.0 g)

●

Inner periphery of Connecting Piece (A)

[19]

(0.5 g)

●

Tapping Screw (W/Flange) D4

[38][49][57]

---------------------------- 1.96 ± 0.49 N

•

m (20 ± 5 kgf

•

cm)

●

Machine Screw (W/Washer) M4 X 8 (Black)

[65]

--------------------- 1.96 ± 0.49 N

•

m (20 ± 5 kgf

•

cm)

●

Machine Screw M4 X 30 (Black)

[40]

------------------------------------ 1.96 ± 0.49 N

•

m (20 ± 5 kgf

•

cm)

●

Seal Lock Hex. Socket HD. Bolt M3

[1][12]

---------------------------- 2.45 ± 0.49 N

•

m (25 ± 5 kgf

•

cm)

●

Hex. Socket HD. Bolt M5 X 16

[69]

--------------------------------------- 3.43 to 6.37 N

•

m (35 to 65 kgf

•

cm)

●

Special Bolt M4

[5]

------------------------------------------------------------ 4.4 ± 1.0 N

•

m (45 ± 10 kgf

•

cm)

●

Machine Screw (W/Washer) M3.5 X 6

[42]

----------------------------- 0.6 ± 0.15 N

•

m (6 ± 1.5 kgf

•

cm)

Check the following after reassembly:

(1) Confirm normal switching operation of Switch (E) (1p Screw Type) W/Lock

[41]

.

(2) Confirm that the stroke speed changes depending on the turning amount of Controller

[43]

.

(3) Confirm that the blade can be attached securely.

Upon completing disassembly and repair, measure the insulation resistance and conduct an insulation test

(dielectric strength test).

Insulation resistance: 7 M

Ω

or more with 500 V DC megohm tester.

Dielectric strength:

AC 4,000 V for 1 minute, with no abnormalities ---- 110 V, 220 V, 230 V, 240 V

AC 2,500 V for 1 minute, with no abnormalities ---- 120 V

After no-load operation for 30 minutes, the no-load current value should be as specified below at a

frequency of 50/60 Hz.

Voltage (V)

110

120

220

230

240

Current (A) Max.

4.0

3.0

1.8

1.8

1.8

Screw Tightening Torque

Checking after Reassembly

Application of Lubricant

Insulation Test

No-load Current