--- 17 ---

8-3-3. Adjustment of the Rip Fence (Fence Ass'y)

Before shipment from the factory the saw blade is set parallel to

the miter-gauge groove and the rip fence is adjusted parallel to

the miter-gauge groove. Check and adjust the parallelism of the

rip fence with the following procedures in order to assure

accuracy and prevent kickback when ripping.

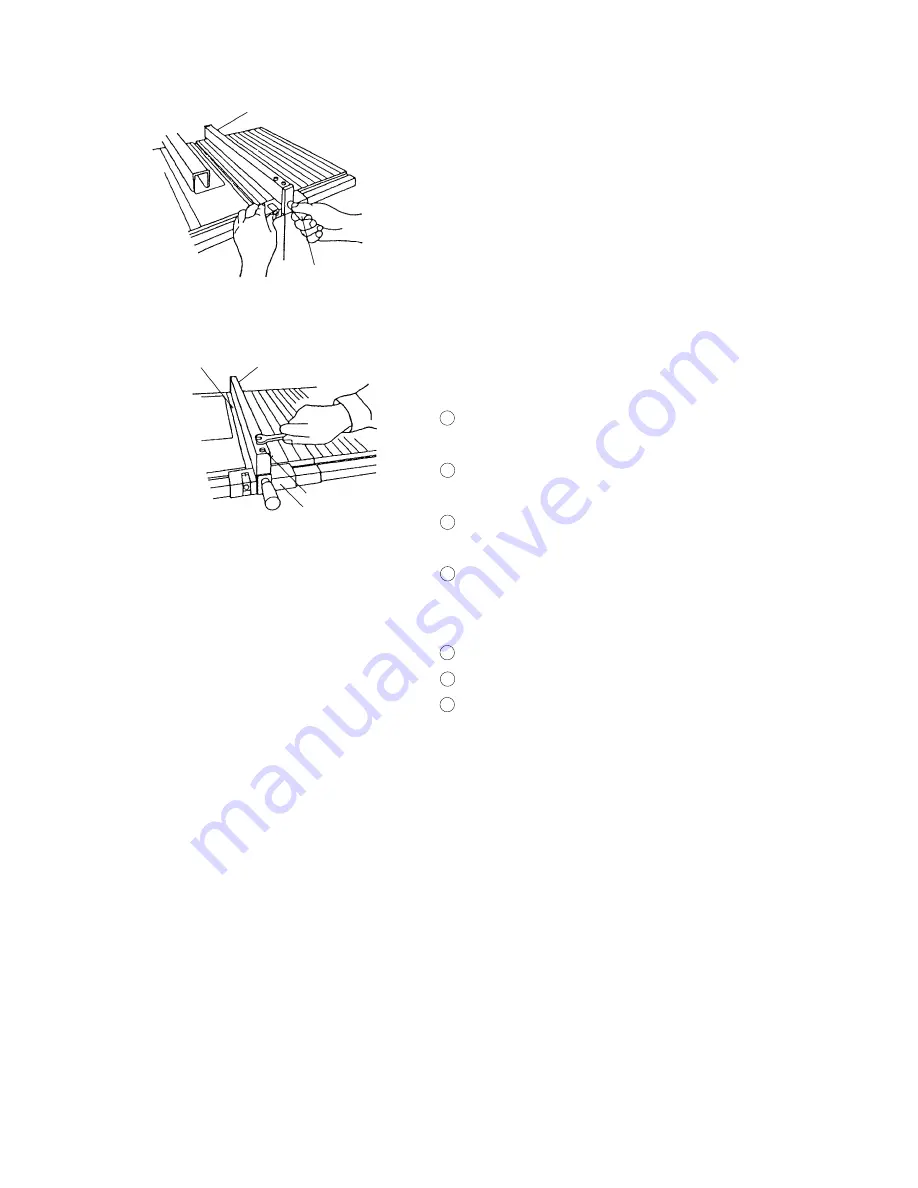

(1) Loosen clamp handle (A) (see Fig. 18-a).

(2) Position the rip fence at one edge of the miter-gauge groove.

(3) Lock the rip fence to the table with clamp handle (A).

The edge of the rip fence should then line up parallel with the

miter-gauge groove.

(4) If the edge of the rip fence is not parallel with the miter-

gauge groove,

1 Loosen the two 6 mm bolts securing the parallel bracket to

the fence bracket (see Fig. 18-b).

2 Loosen clamp handle (A), align the rip fence parallel to the

groove, and tighten the clamp handle (A).

3 While holding the parallel bracket to prevent movement,

tighten the two 6 mm bolts previously loosened.

4 Loosen clamp handle (A), move and return the parallel

bracket adjacent to the groove, tighten clamp handle (A)

and verify that the parallel bracket is parallel to the groove.

5 Repeat adjustment until it is parallel.

6 After adjustment, tighten the two 6 mm bolts.

7 On completion of adjustment, recheck the rip fence is

parallel with the miter-gauge groove.

Rip fence

Fig. 18-a

Clamp handle (A)

6 mm Bolt

Fig. 18-b

Fence bracket

Groove

Rip fence

Summary of Contents for C 10RA

Page 34: ... 30 Motor Parts Fig 30 ...

Page 45: ... 41 Assembly Diagram for C 10RA ...

Page 46: ... 42 Assembly Diagram for C 10RA ...