Plastic gauge

1. Using the plasti-gauge

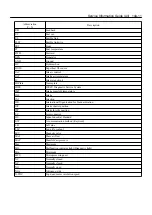

Type

Measurable range

PG-1 (Green)

:

0.025 to 0.076 mm { 0.00098

to 0.00299 in }

PR-1 (Red)

:

0.051 to 0.152 mm { 0.00201

to 0.00598 in }

PB-1 (Blue)

:

0.102 to 0.229 mm { 0.00402

to 0.00902 in }

Method for measuring clearance between the connecting

rod bearing and the crank pin

Clean the connecting rod and bearing, and assemble the

bearing to the connecting rod.

Cut the PLASTIGAUGE to the width of the crank pin

and lay it parallel avoiding the crank pin oil hole.

Align the markings on the connecting rod and cap, and

assemble them on the crank pin. Apply molybdenum

disulfide to the threaded portion and the seating surface

of the tightening bolts, and tighten the caps alternately to

the specified torque.

Caution

:

・

Never move the connecting rod when using

PLASTIGAUGE.

Gently remove the cap and the connecting rod, and

measure the width of the flattened PLASTIGAUGE using

the scale printed on the packaging.

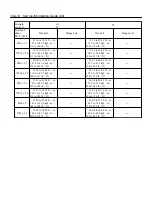

Method for measuring clearance between the crank

bearing and the crank journal

Clean the bearing, as well as the cylinder block and

crankcase bearing mounting surfaces, and assemble to the

cylinder block and crankcase.

Gently place the crankshaft on the cylinder block, and

settle it by turning it approximately 30 degrees.

Cut the PLASTIGAUGE to the width of the crank journal

and lay it parallel avoiding the journal oil hole.

Gently place the crankcase on the cylinder block, and

apply molybdenum disulfide to the threaded portion and

the seating surface of the tightening bolts. Tighten to the

specified torque in the specified order .

Caution

:

・

Never move the connecting rod when using

PLASTIGAUGE.

Gently remove the crankcase, and measure the width of

the flattened PLASTIGAUGE using the scale printed on

the packaging.

14A-4 Service Information Guide (All)

Find manuals at https://best-manuals.com

Find manuals at https://best-manuals.com